High-voltage lithium ion battery, composite electrode couple and preparation methods of high-voltage lithium ion battery and composite electrode couple

A lithium-ion battery and composite electrode technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, battery electrodes, secondary batteries, etc., can solve problems such as short circuit of adjacent battery cells, avoid potential safety hazards, and improve dynamic consistency and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

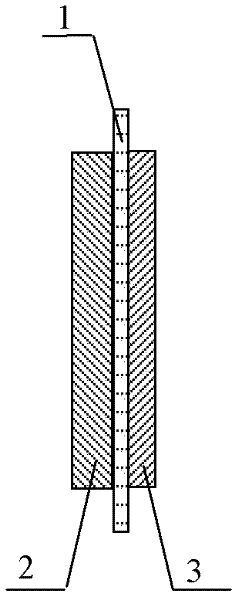

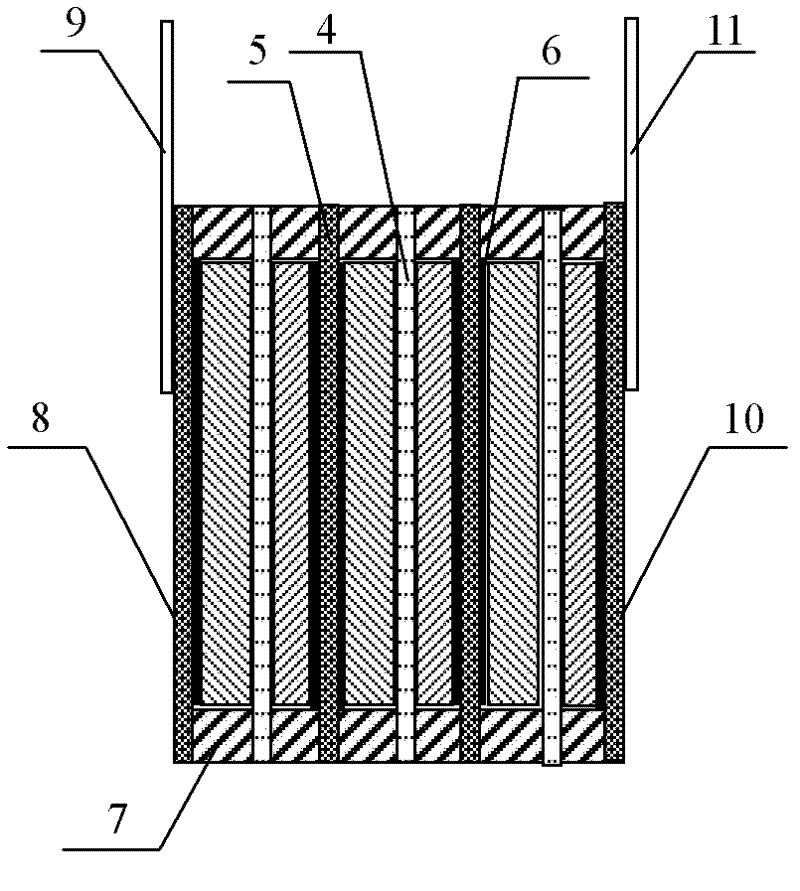

[0018] Preparation of composite electrode pair: polyethylene oxide, LiFePO 4 / C and carbon black are composed of adhesive by weight percentage: carbon black: LiFePO 4 / C=8:7:85 is mixed in deionized water to obtain positive electrode slurry, and the slurry is evenly coated on the surface to be coated with a layer of inorganic nanoparticles (thickness is less than 5 microns, and the inorganic nanoparticles are SiO 2 、Al 2 o 3 、TiO 2 etc.), dry one side of the non-woven porous diaphragm at 80°C; then sodium carboxymethyl cellulose, carbon black, Li 4 Ti 5 o 12 (Lithium titanate) is composed of Li by weight percentage 4 Ti 5 o 12 : carbon black: binder=90: 3: 7 is mixed in deionized water to obtain the negative electrode slurry, and the slurry is evenly coated on the surface to be coated with a layer of inorganic nanoparticles (thickness is less than 5 microns, and the inorganic nanoparticles are SiO 2 、Al 2 o 3 、TiO 2 etc.), dry the other side of the non-woven porous...

Embodiment 2

[0022]Preparation of composite electrode pair: PVDF (polyvinylidene fluoride), modified lithium manganate and carbon black are composed of adhesive by weight percentage: carbon black: lithium manganate=8: 7: 85 mixed with NMP (N-methyl pyrrolidone), fully mixed to make positive electrode slurry. Apply the slurry evenly on one side of the polyolefin porous diaphragm, and dry at 60-110°C; PVDF, lithium titanate and carbon black are composed of lithium titanate: carbon black: adhesive = 90:3 :7 mixed in NMP, fully mixed to make negative electrode slurry, and then evenly coated the slurry on the other side of the polyolefin porous diaphragm, dried at 60 ~ 110 ° C, and then pressed in the range of 6 ~ 20MPa The sheet was cut to make a composite electrode pair.

[0023] Preparation of electronically conductive adhesive layer: PVDF and carbon black weight percentages are composed of carbon black: PVDF=7:3 dissolved in NMP to make a slurry, coated on both sides of the composite elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com