Application of metal-organic framework in adsorption type heat pump distillation

A metal-organic framework and adsorption heat pump technology, applied in fractionation and other directions, can solve the problems of small circulation volume and low rectification heat recovery, and achieve the effects of increasing heat recovery, strengthening heat transfer, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1,3-Butadiene is an important chemical raw material for synthetic rubber, mainly derived from the separation of C4 fractions. At present, pressurized extraction and rectification are often used to separate butadiene in factories. The boiling point of butadiene is -4.4°C, and the rectification adopts a pressurized method, so that the overhead steam can be condensed with water; the boiling point of each component in the C4 fraction is close, adding an extractant to improve the relative volatility between butadiene and other components The pressure at the top of the rectification column is 0.55MPa, the temperature at the top of the column is 47°C, and the temperature at the bottom of the column is 112°C.

[0024] In the heat pump rectification process for butadiene separation and adsorption of the present invention, butadiene is extracted and rectified, the extractant is acetonitrile, the pressure at the top of the tower is normal pressure, the temperature at the top of the...

Embodiment 2

[0028] In the process of butadiene separation and adsorption heat pump rectification of the present invention, butadiene adopts vacuum distillation, the tower top pressure is 19.7kPa, the tower top temperature is -40°C, and the tower bottom temperature is -9°C; the adsorption of the adsorption heat pump The agent adopts metal-organic framework MOF-177[Zn 4 O(btb) 2 ] (The synthesis method and skeleton structure of this material can be found in literature [Millward A R, Yaghi O M. Metal-Organic Frameworks with Exceptionally High Capacity for Storage of Carbon Dioxide at Room Temperature[J]. Journal of the American Chemical Society, 2005 , 127(51): 17998-17999]), carbon dioxide is used as the heat pump working fluid, and the cycle adsorption capacity is 0.31kg / kg. One part of heat energy input to the adsorption heat pump can recover 0.85 part of the heat energy of the rectification system.

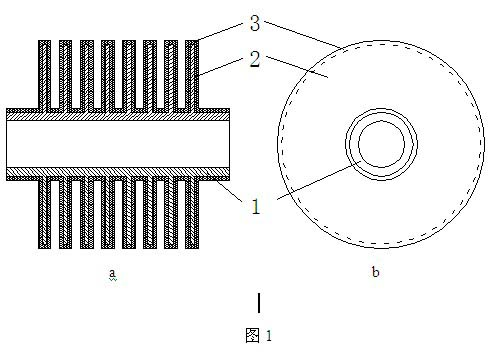

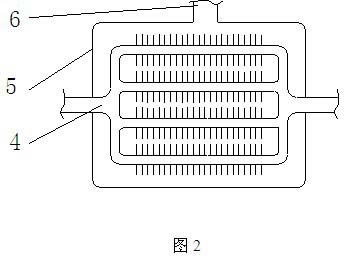

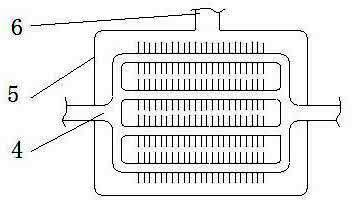

[0029] Among them, the specification parameters of the adsorption bed heat exchange tub...

Embodiment 3

[0032] In the heat pump rectification process for separation and adsorption of butadiene in the present invention, butadiene adopts pressurized extraction and rectification, the extractant is N,N-dimethylformamide, the pressure at the top of the tower is 600kPa, and the temperature at the top of the tower is 40°C , the temperature of the tower kettle is 138°C; the adsorbent of the adsorption heat pump adopts metal organic framework Na- rho -ZMOF [In 48 (C 5 N 2 o 4 h 2 ) 96 Na 48 (C 2 h 5 Oh) 96 (H 2 O) 192 ] (the synthetic method and framework structure of this material, can refer to literature [Nalaparaju A, Zhao X S, Jiang J W. Molecular Understanding for the Adsorption of Water and Alcohols in Hydrophilic and Hydrophobic Zeolitic Metal-Organic Frameworks [J]. Journal of Physical Chemistry. C, 2010, 114(26): 11542-11550]), ethanol is the working fluid of the heat pump, and the cycle adsorption capacity is 0.21kg / kg. One part of heat energy input to the adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com