Permanent hydrophilic modification method for surface of porous membrane and porous membrane obtained by same

A technology of hydrophilic modification and porous membrane, which is applied in the field of porous membrane, which can solve the problems of membrane pore clogging and difficult adsorption, and achieve the effect of small pore size change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

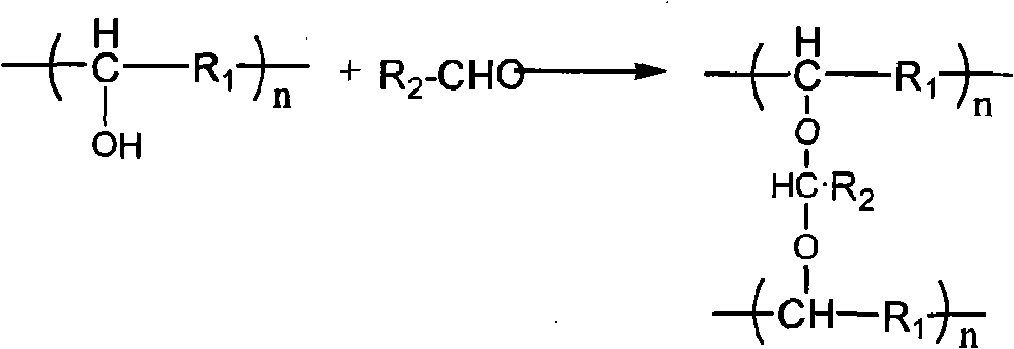

Method used

Image

Examples

Embodiment 1

[0051] The polyvinylidene fluoride hollow fiber membrane prepared by the dry-wet method has a measured pure water flux of 750L / m 2 ·h·0.1MPa, the contact angle is 89°. Soak the polyvinylidene fluoride film in a vinyl alcohol-vinyl acetate copolymer solution, the composition of which is 0.2kg vinyl alcohol-vinyl acetate+94.8kg ethanol+5kg deionized water. The soaking temperature is 25°C, and the soaking time is 10 hours. Then take it out and dry it for 8 hours. The dried porous membrane was cross-linked by immersing in 1.0%wt glutaraldehyde aqueous solution, and the temperature of the glutaraldehyde aqueous solution was kept constant at 30°C. After 3 hours, the porous membrane was taken out and rinsed in deionized water for 1 hour. The measured pure water flux is 1300-1400L / m 2 ·h·0.1MPa, the contact angle is 55°.

Embodiment 2

[0053] Hollow fiber polyvinyl chloride membrane prepared by thermally induced phase separation, with a pure water flux of 800L / m 2 ·h·0.1MPa, the contact angle is 93°. The film is first soaked in vinyl alcohol-vinyl acetate solution, and the components of the solution are 20kg vinyl alcohol-vinyl acetate+60kg methanol+20kg deionized water. The solution temperature was kept constant at 15°C. The soaking temperature is 15°C, the film is taken out after soaking for 12 hours, and the drying time is 8 hours. Cross-linking was carried out with a glyoxal solution with a constant temperature of 15° C. and a concentration of 10% wt. After half an hour, the membrane was taken out and rinsed in deionized water for 2 hours. The measured pure water flux is 1780L / m 2 ·h·0.1MPa, the contact angle is 54°.

[0054] Example 3:

[0055] Flat-plate polypropylene nitrile membrane prepared by dry-wet method, the pure water flux is 750L / m 2 ·h·0.1MPa, the contact angle is 90°. The film was ...

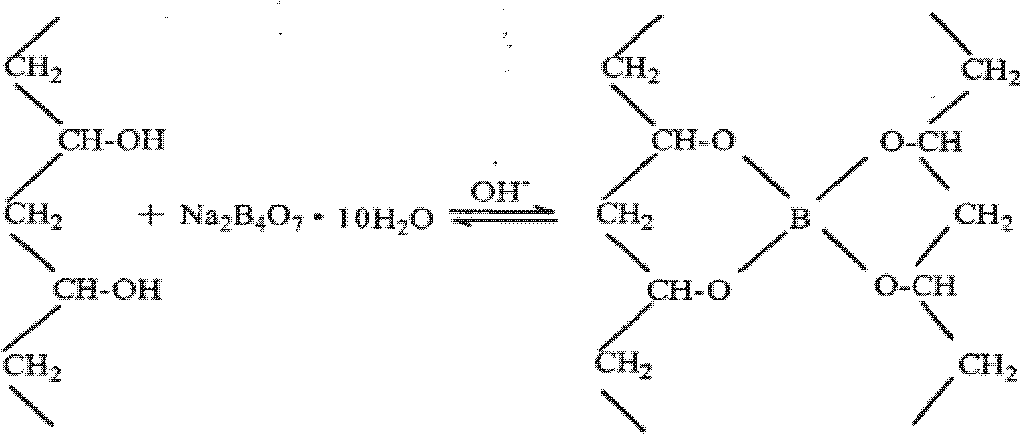

Embodiment 4

[0057] Same as Example 3, the difference is that the membrane is a polyethersulfone hollow fiber membrane, and the pure water flux is 420L / m 2 ·h·0.1MPa, the contact angle is 92°, formaldehyde is replaced by borax, the mass concentration of borax is 2.0%, and the rest are the same. The measured pure water flux is 1380L / m 2 ·h·0.1MPa, the contact angle is 55°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com