Wiper motor speed regulation system with pulse-width modulation and voltage regulation

A technology of motor speed regulation and pulse width modulation, which is used in motor generator/starter, vehicle cleaning, starter of a single DC motor, etc., can solve the problems of low coil utilization, high cost, complicated wiring, etc. The effect of reducing production cost, extending service life and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

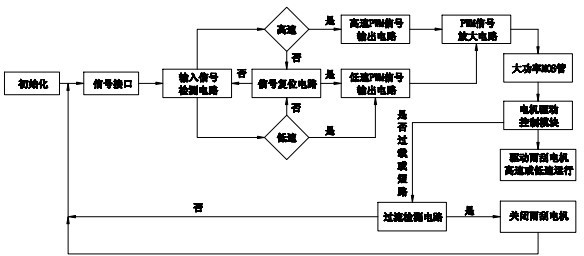

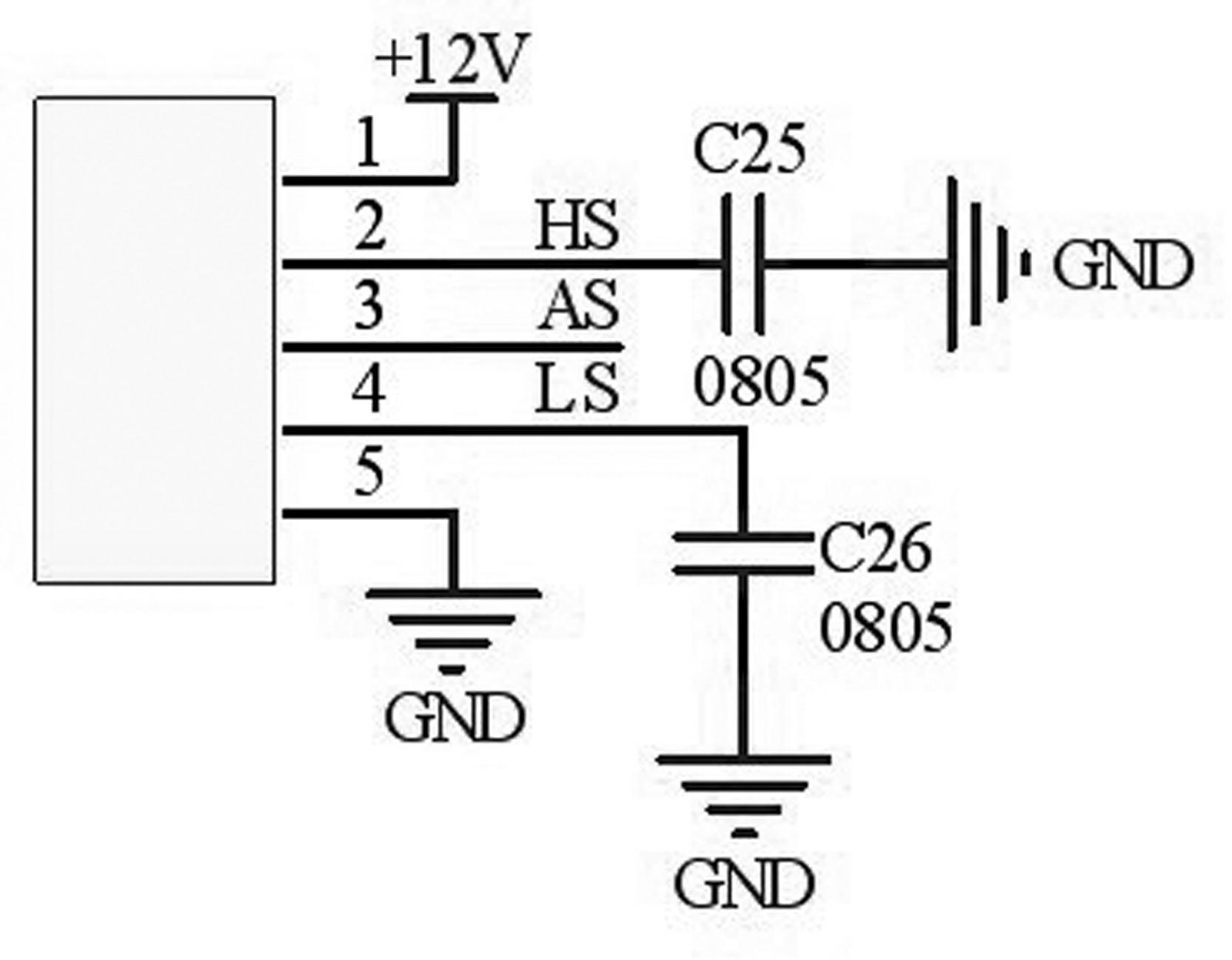

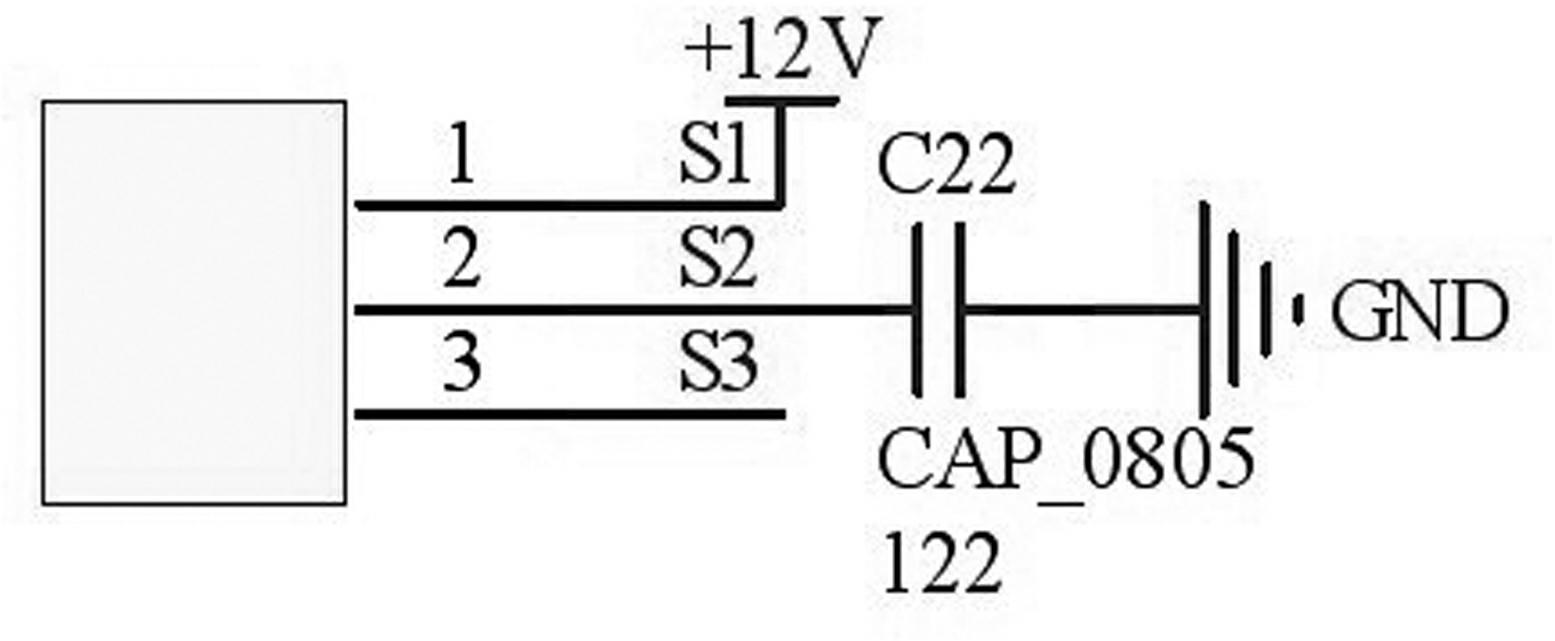

[0015] like figure 1 The figure shows a wiper motor speed control system with pulse width modulation and voltage regulation, including a signal processing module, an integrated controller, and a motor drive control module. The signal processing module includes a signal interface, an input signal detection circuit, and a signal reset Circuit, overcurrent detection circuit, integrated controller including high-speed PWM signal output circuit, low-speed PWM signal output circuit, PWM signal amplification circuit, high-power MOS tube, signal interface receives external signal, and transmits the received signal to input signal detection circuit, the input signal detection circuit sends the signal to the signal reset circuit or integrated controller through detection and judgment, and the integrated controller outputs the signal through the high-speed PWM signal output circuit or low-speed PWM signal according to the high-speed and low-speed operation information of the received sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com