Water-circulating vacuum feeder

A vacuum feeding machine and water circulation technology, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of huge noise application site, large noise pollution, impossible to meet GMP requirements, etc., to overcome the problem of gravity acceleration , Solve the problem of dust pollution and avoid the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

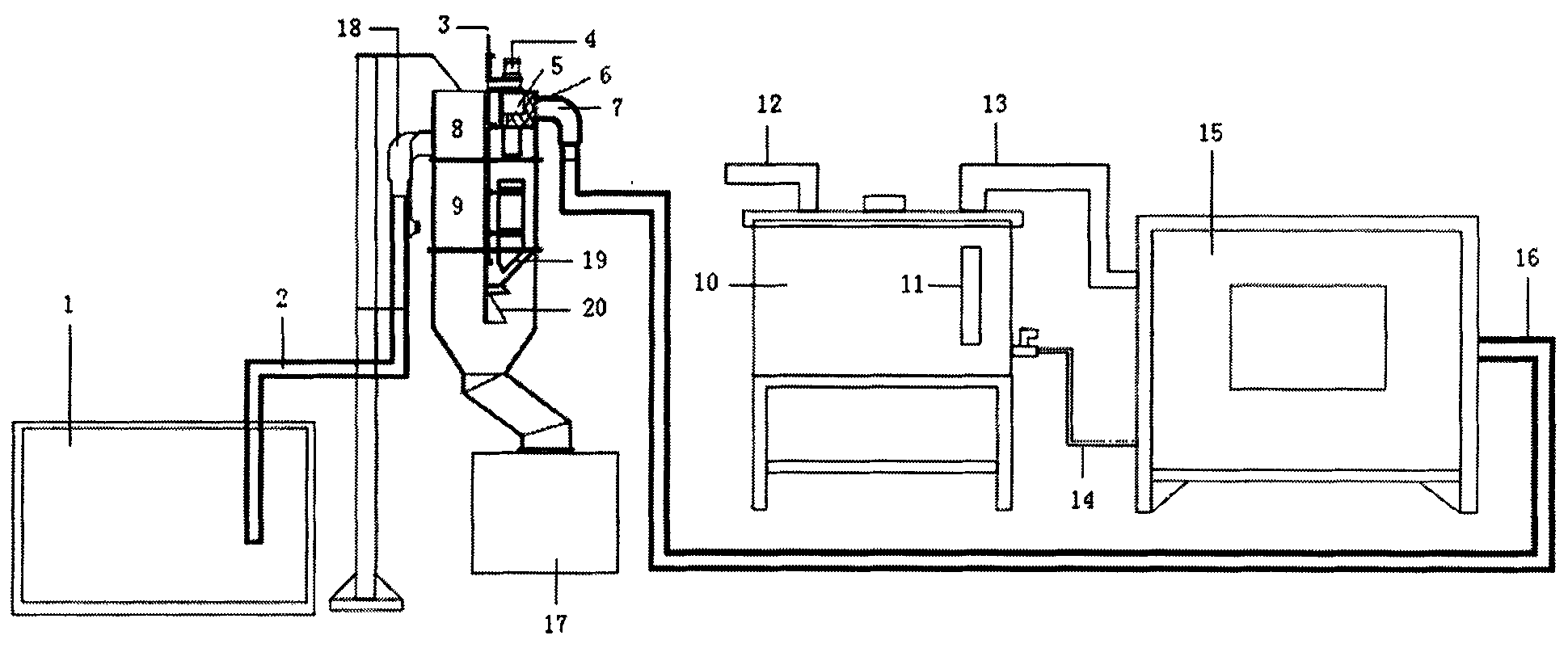

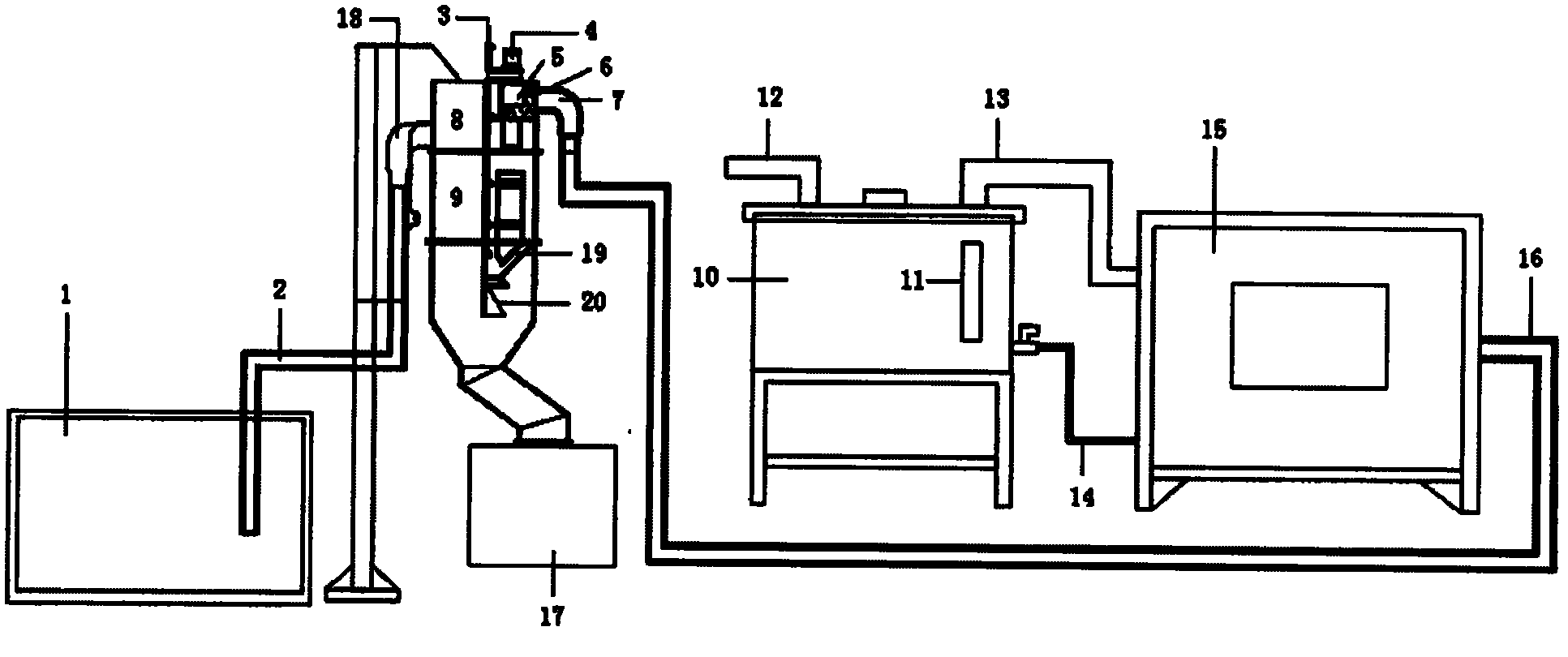

[0017] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0018] Such as figure 1 A water cycle vacuum feeding machine shown includes a storage box, a stirring motor, a feeding storage bin, a discharging storage bin and a receiving device. The storage box 1 is connected to the feeding storage bin through a pumping pipeline 2 The feed port 18, the feed storage bin 8 are respectively equipped with a stirring motor 4, an air pump valve 3, the stirring motor is connected to the stirring blade 19, the stirring blade adopts a spiral stirring blade, and Escherichia coli is respectively housed in the feeding storage bin. The material filter device 5, the air filter device 6, the suction port 7 of the feed storage bin are connected to the suction inlet 16 of the water circulation vacuum pump through the pipeline, the water circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com