Straw-degrading composite microbial inoculum and application thereof in pretreatment of ethanol production

A compound bacterial agent and pretreatment technology, applied in the direction of microorganism-based methods, bacteria, microorganisms, etc., can solve the problems of large environmental impact, low degradation efficiency, and high operation cost, and achieve simple equipment, efficient pretreatment, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

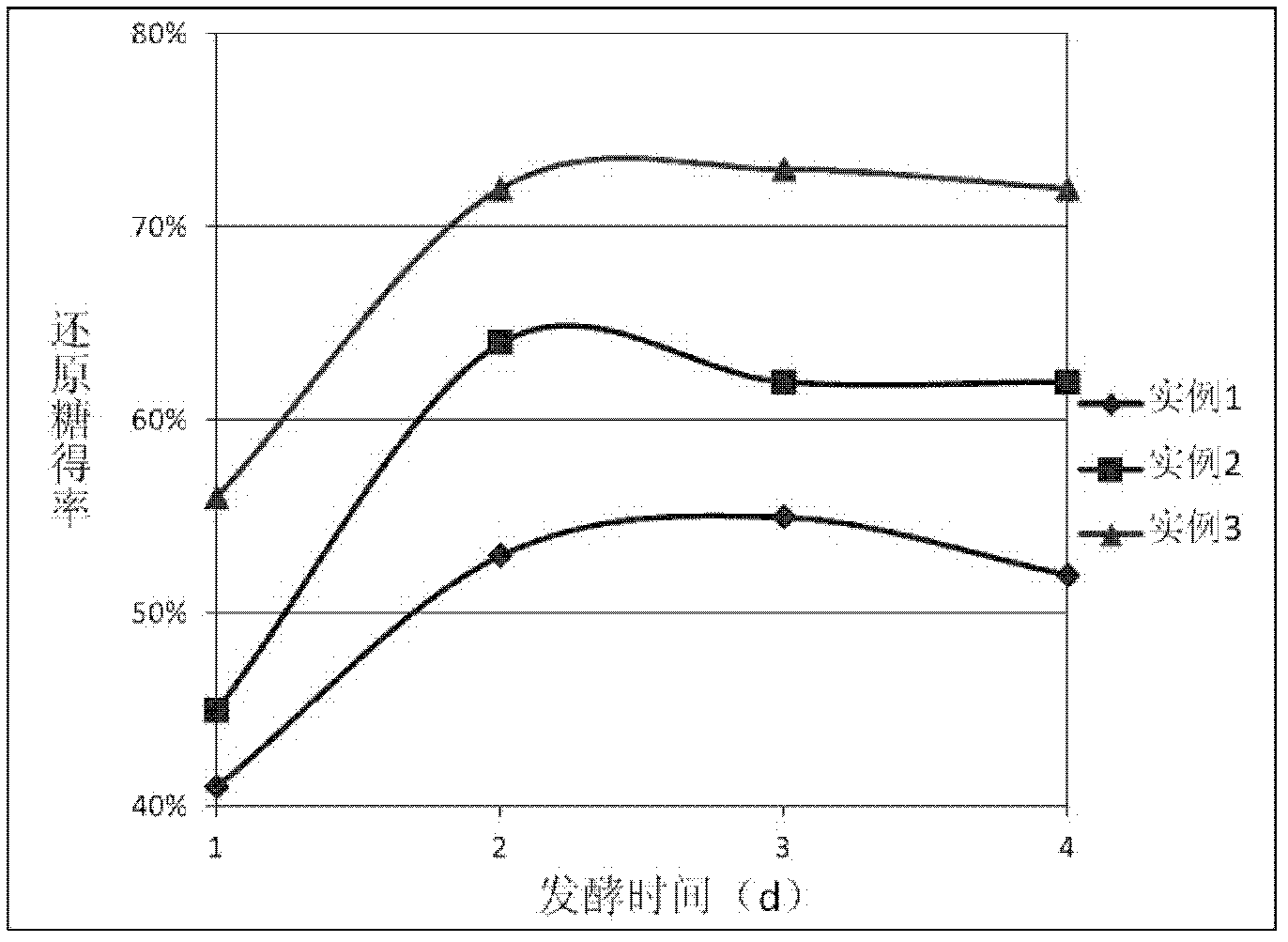

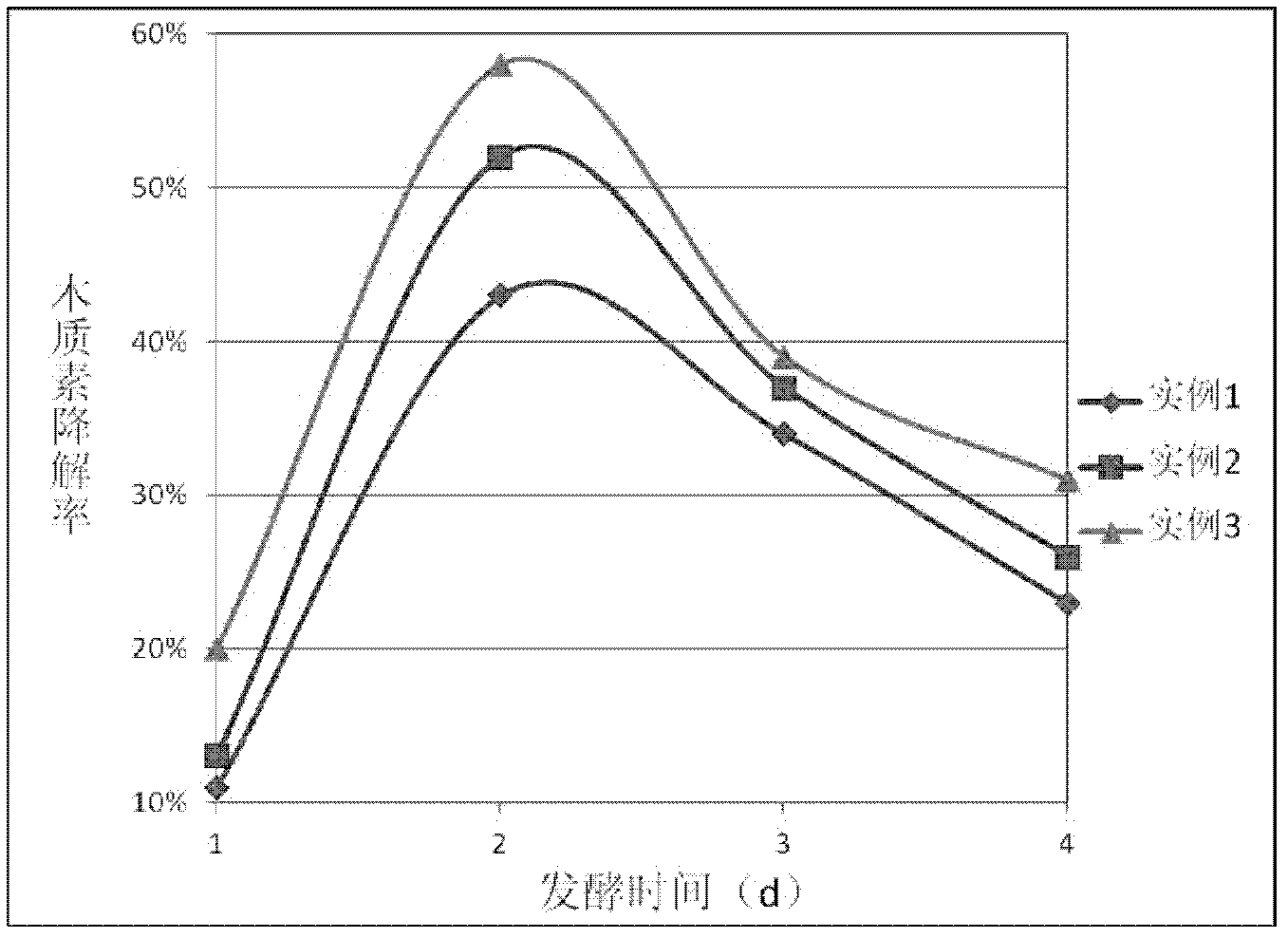

Embodiment 1

[0027] A method for applying straw high-efficiency degradation compound bacterial agent in ethanol production pretreatment, comprising the following steps:

[0028] 1) The rice straw is crushed to a particle size of 0.8 cm by crushing equipment to form straw powder;

[0029] 2) soak the straw powder in 0.1% ammonia solution for purification treatment for 48 hours, take it out and squeeze until no water flows out;

[0030] 3) Add 40% of its quality nutrient solution to the purified straw to make a fermentation substrate; spray lignin-degrading bacteria and cellulose-degrading bacteria liquid into the fermentation substrate, and the quality of the bacterial liquid and the fermentation substrate The ratio is 1:3, and the bacterial concentration in the culture medium is 1×10 7 cfu / ml;

[0031] 4) After 2 days of fermentation treatment to obtain a fermentation product, the fermentation product was filtered and washed until neutral to obtain a pretreated product.

[0032] In this...

Embodiment 2

[0037] A method for applying straw high-efficiency degradation compound bacterial agent in ethanol production pretreatment, comprising the following steps:

[0038] 1) The rice straw is crushed to a particle size of 0.8 cm by crushing equipment to form straw powder;

[0039] 2) Soak the straw powder in 0.5% ammonia solution for purification treatment for 36 hours, take it out and squeeze until no water flows out;

[0040] 3) Add 30% of its mass nutrient solution to the purified straw to make a fermentation substrate; spray lignin-degrading bacteria and cellulose-degrading bacteria liquid into the fermentation substrate, and the quality of the bacterial liquid and the fermentation substrate The ratio is 1:5, and the bacterial cell concentration in the culture medium is 7×10 7 cfu / ml;

[0041] 4) After 2 days of fermentation treatment to obtain a fermentation product, the fermentation product was filtered and washed until neutral to obtain a pretreated product.

[0042] In th...

Embodiment 3

[0047] A method for applying straw high-efficiency degradation compound bacterial agent in ethanol production pretreatment, comprising the following steps:

[0048] 1) The rice straw is crushed to a particle size of 0.5 cm by crushing equipment to form straw powder;

[0049] 2) Soak the straw powder in 1.0% ammonia solution for purification treatment for 24 hours, take it out and squeeze it until no water flows out;

[0050] 3) Add 25% of its quality nutrient solution to the purified straw to make a fermentation substrate; spray lignin-degrading bacteria and cellulose-degrading bacteria liquid into the fermentation substrate, and the quality of the bacterial liquid and the fermentation substrate The ratio is 1:7, and the bacterial concentration in the culture medium is 7×10 8 cfu / ml;

[0051] 4) After 2 days of fermentation treatment to obtain a fermentation product, the fermentation product was filtered and washed until neutral to obtain a pretreated product.

[0052] In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com