Solution phase inversion membrane preparation solvent replacement and digestion device

A technology of solution phase inversion and membrane solvent, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of large solvent residue, low solvent recovery rate, solvent loss, etc., to reduce investment and operation Cost, avoiding environmental pollution, and improving the effect of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

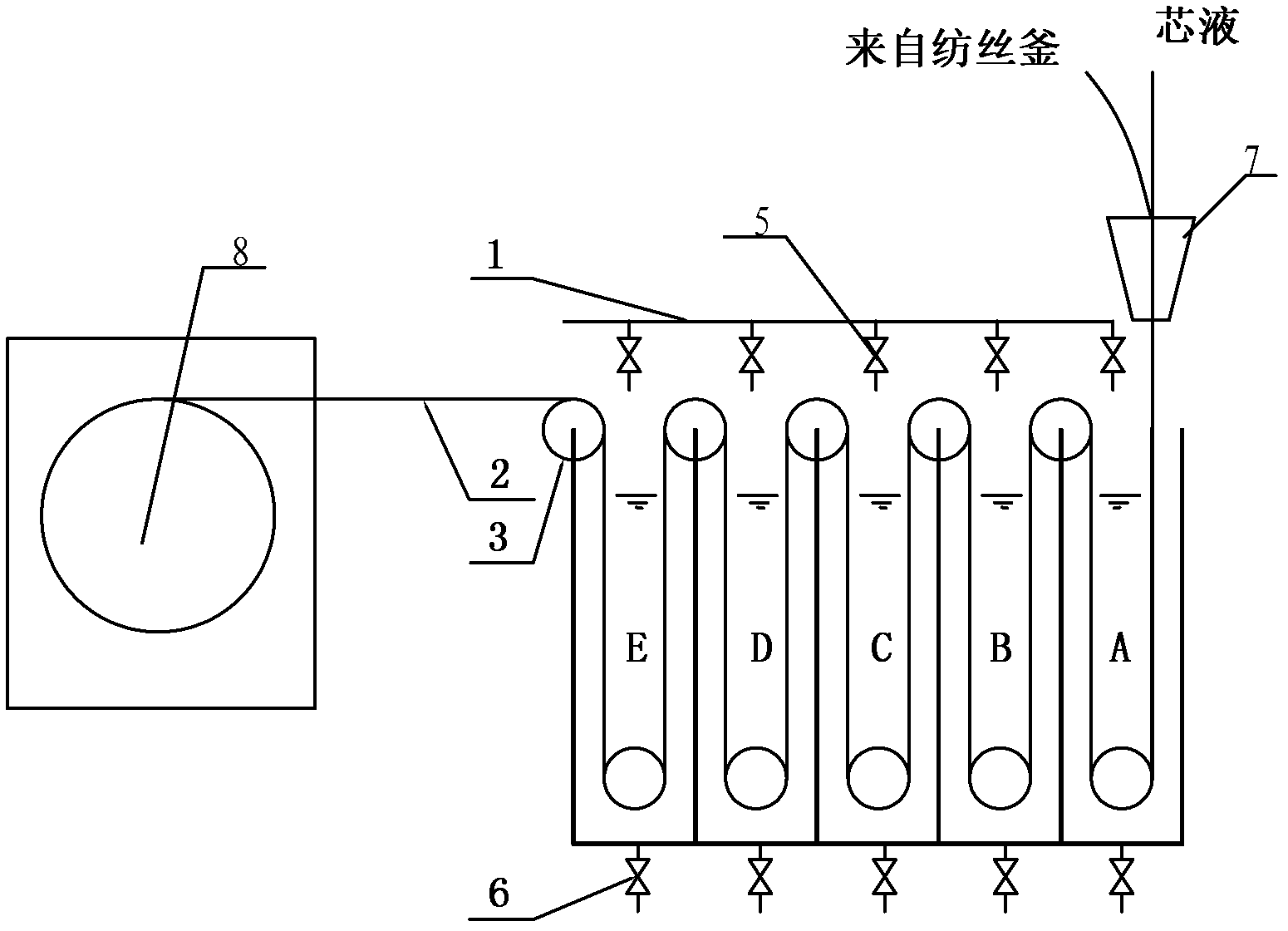

[0031] Device structure: see figure 2, the coagulation baths A, B, C, D, E are arranged in sequence from front to back, a tank wall 11 is shared between the two coagulation baths, the lower section of the coagulation bath E is provided with an injection port 9, and the upper section of the coagulation bath A is provided with an outlet 4, so The above-mentioned adjacent coagulation baths are all communicated via pipeline 10 (water pumps may or may not be installed on the pipeline 10), the upper end of the pipeline 10 is located at the upper section in the next adjacent coagulation bath, and the lower end of the pipeline 10 is located at the adjacent The lower section of the previous coagulation bath. The heights of the upper ends of the pipelines in the plurality of coagulation baths decrease successively from back to front (or equal height), and the bottom of each coagulation bath is also equipped with a discharge valve 6 for emptying the liquid in the tank when the system is...

Embodiment 2

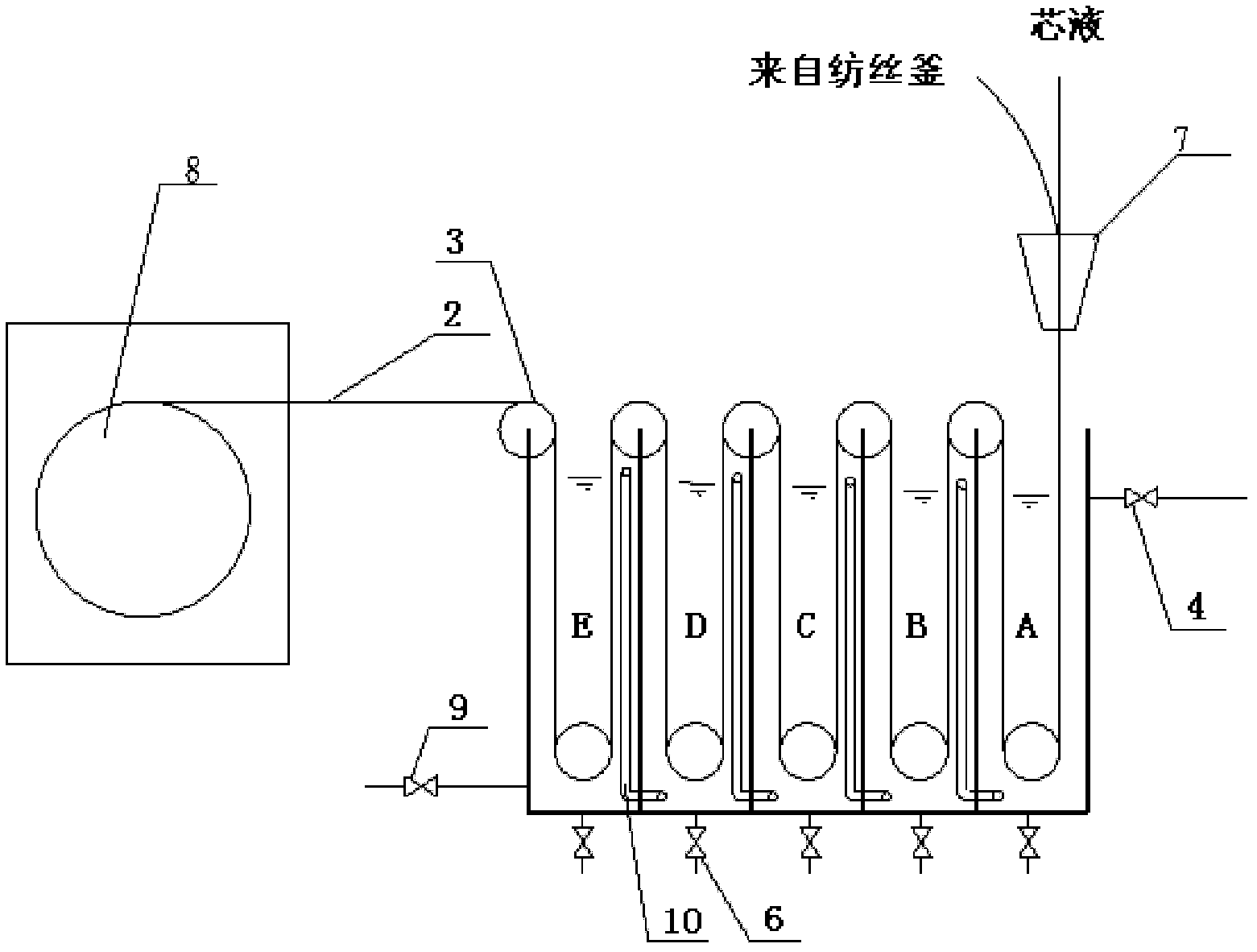

[0035] Device: see image 3 , different from Embodiment 1, the pipeline 10 is canceled, and the flow holes 12 on the tank wall 11 are communicated between adjacent coagulation baths, and the flow holes 12 are all positioned at the upper section of the tank wall 11 (the height of the flow holes 12 The overflow liquid level set for the tank), the center of the coagulation bath is vertically provided with a partition 13 along the axial direction of the pulley 3, and each coagulation bath is divided into two parts, and the lower end of the partition 13 is 20 ~ 50mm, the upper end of the separator 13 is 20-50mm higher than the liquid surface, and the lower end has a gap from the bottom of the tank for the membrane 2 and the liquid to pass through. The injection port 9 is located in the upper section of the coagulation bath E (preferably not lower than the liquid level). The height of the flow hole 12 on the tank wall 11 decreases successively from back to front (or is at a position...

Embodiment 3

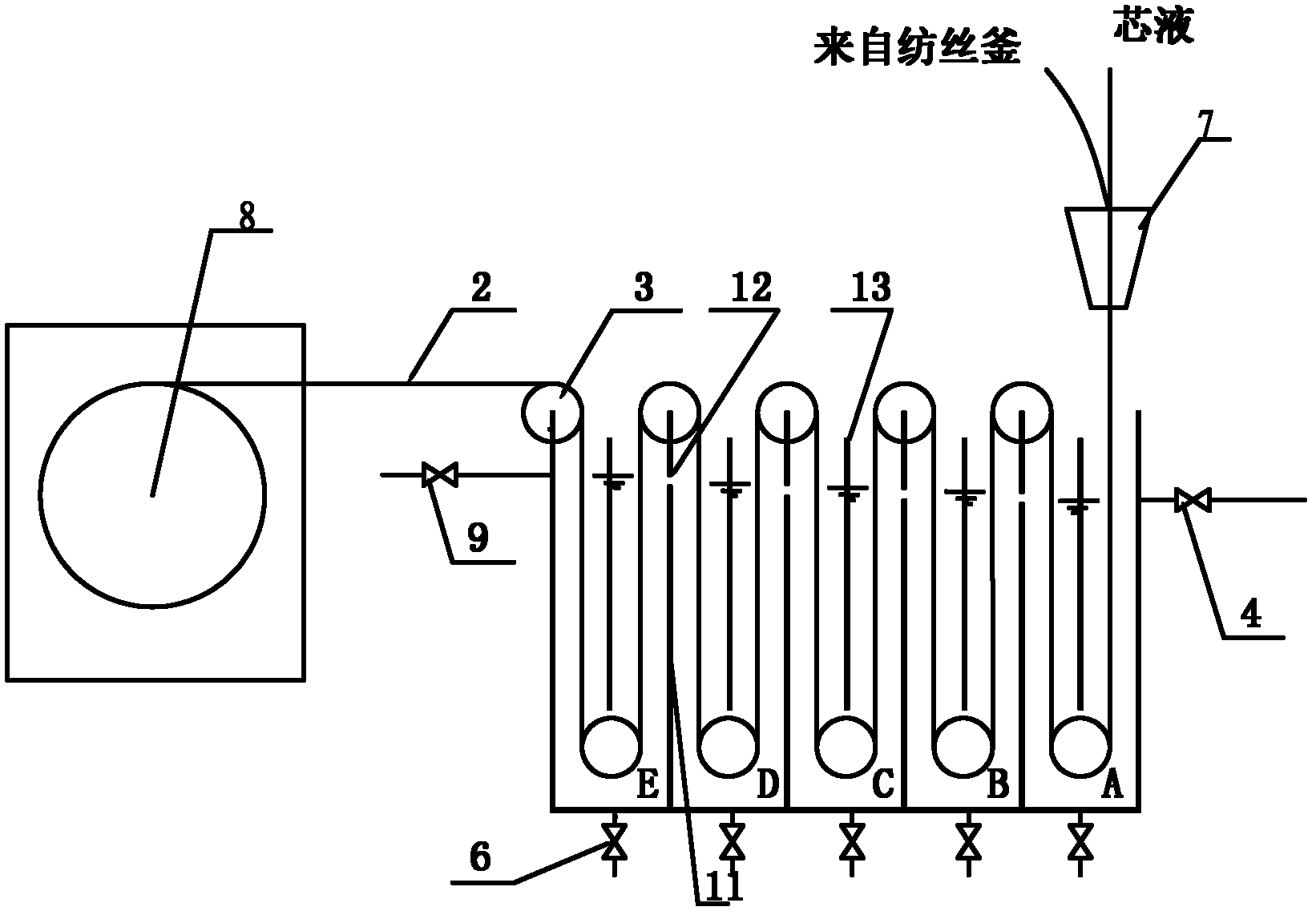

[0039] Device: see Figure 4 , and embodiment 2 is different in that the partition 13 is canceled, the injection port 9 is located in the lower section of the coagulation bath E, and the positions of the flow holes 12 on the walls 11 of the coagulation bath are staggered up and down. In this embodiment, the coagulation bath E The flow hole 12 of coagulation bath D is in the upper section of the tank wall (its height is the overflow height set by coagulation bath E), and the flow hole 12 of coagulation bath D and coagulation bath C is in the lower section of the tank wall (close to the bottom of the tank) , in such a staggered arrangement (this embodiment is only an example, not limited to this arrangement). All the other are with embodiment 2.

[0040] crafting process:

[0041] After the fresh water enters the coagulation bath E, the liquid level of the coagulation bath E rises, and overflows from the flow hole in the upper section of the tank wall to the coagulation bath D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com