Cast iron product with protective and decorative coating and plating

A cast iron product and coating technology, which is applied in the field of cast iron products, can solve problems such as easy yellowing, poor protection and decoration performance, and achieve the effects of reducing pollution, low cost, and little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

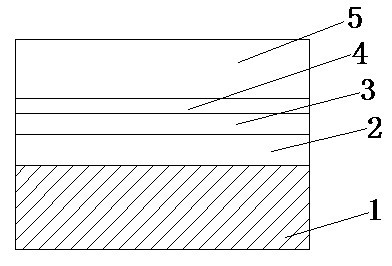

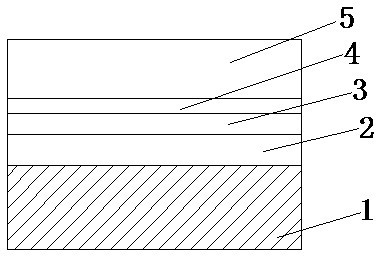

[0024] Such as figure 1 As shown, the cast iron products with protective decorative coating, on the base material of ductile iron casting 1, from bottom to top are: primer layer, chrome plating layer 4 and top coat layer, the primer layer is made of epoxy family epoxy resin coating 2 and polybutadiene coating 3 with a thickness of 8 μm and 2 μm respectively, the chrome plating layer 4 is a sputtered chrome plating layer with a thickness of 0.5 μm, and the top coat is an acrylic coating 5 with a thickness of 10 μm.

[0025] The production process of this product is as follows: iron casting pretreatment→spraying epoxy epoxy resin, leveling→spraying polybutadiene, baking→sputtering chrome plating→spraying acrylic acid, baking.

Embodiment 2

[0027] Such as figure 1 As shown, the cast iron products with protective decorative coating, on the gray iron casting 1 base material, from bottom to top are: primer layer, chrome plating layer 4 and top coat layer, the primer layer is made of epoxy family epoxy resin coating 2 and polybutadiene coating 3, the thicknesses are 10 μm and 5 μm respectively, the chrome plating layer 4 is ion sputtering hybrid chrome plating layer, its thickness is 1.0 μm, and the top coat is acrylic coating 5, its thickness is 20 μm.

[0028] The production process of this product is as follows: iron casting pretreatment → spraying epoxy epoxy resin, leveling → spraying polybutadiene, baking → ion sputtering mixed chrome plating → spraying acrylic acid, baking.

Embodiment 3

[0030] Such as figure 1 As shown, the cast iron products with protective decorative coating, on the substrate of vermicular graphite cast iron 1, from bottom to top are: primer layer, chrome plating layer 4 and top coat layer, the primer layer is coated with epoxy family epoxy resin Layer 2 and polybutadiene coating 3, the thicknesses are 8 μm and 7 μm respectively, the chrome plating layer 4 is ion chromium plating layer, its thickness is 1.0 μm, the top coat is acrylic coating 5 layers, its thickness is 15 μm,

[0031] The production process of this product is as follows: iron casting pretreatment→spraying epoxy epoxy resin, leveling→spraying polybutadiene, baking→ion chrome plating→spraying acrylic acid, baking.

[0032] The cast iron product of the above-mentioned embodiment having the protective decorative coating is tested for surface gloss, pencil hardness, coating adhesion, and salt spray resistance, and the results are as follows:

[0033] (1) Surface gloss: bright w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com