Silicon through hole etching method

A technology of through-silicon via and etching machine, applied in coating, microstructure device, microstructure technology and other directions, can solve the problems of substrate sidewall corrugation, metal pollution, easy damage of photoresist, etc., to eliminate sidewall corrugation , Easy to remove, avoid metal pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

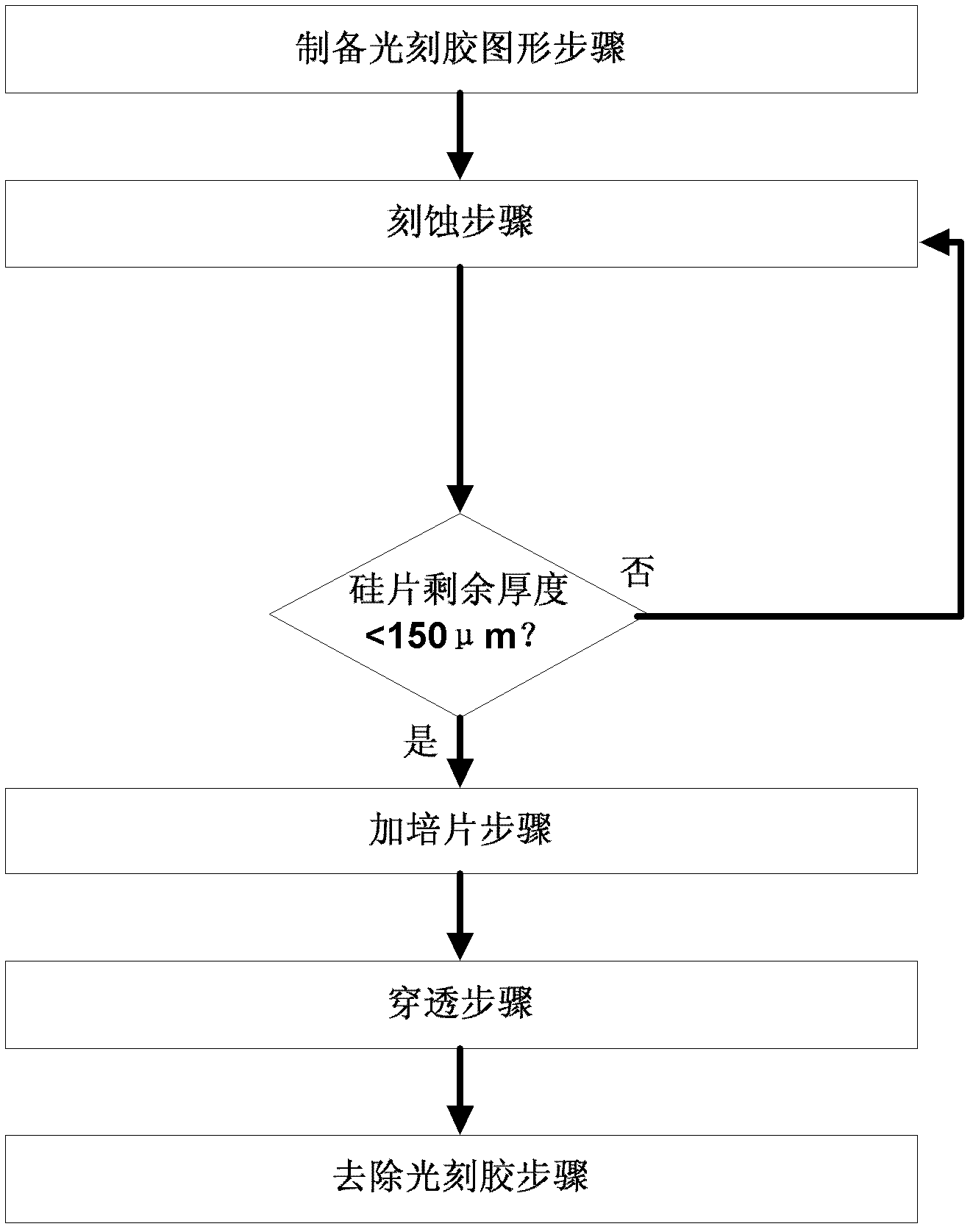

[0026] Embodiment 1, comprising:

[0027] (1) Steps for preparing graphics:

[0028] Uniformly coat photoresist on a 4-inch silicon wafer with a thickness of 200 μm, and the thickness of the photoresist is 10 μm; use a photolithography process and a karl suss MA6 photolithography machine to prepare the required pattern on the photoresist;

[0029] (2) Etching steps:

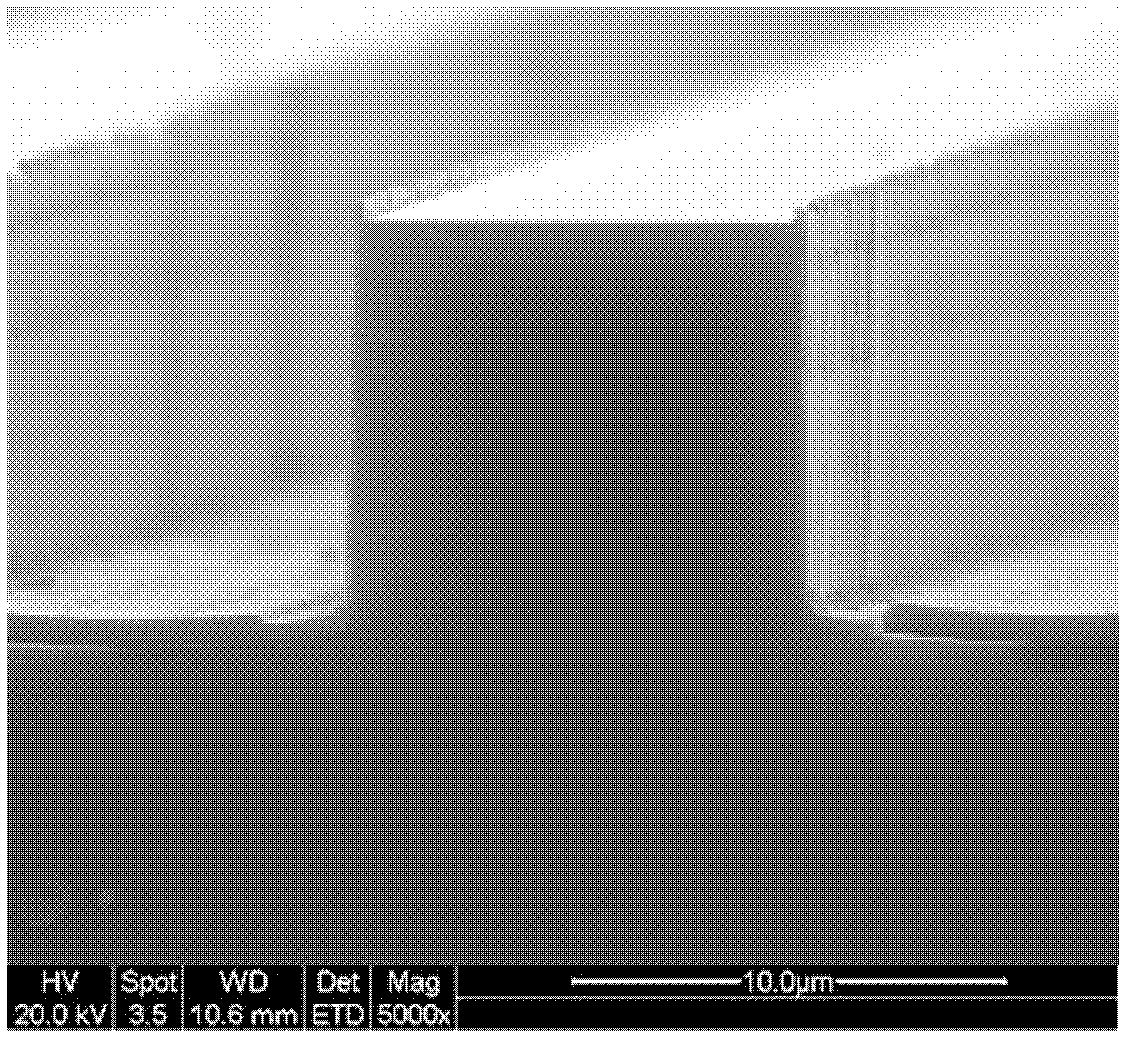

[0030] Using the Bosch process, in the Oxford Plasmalab ICP inductively coupled plasma etching machine of Oxford Instruments, after 50 alternate etching and passivation processes on the silicon wafers prepared for the pattern, the processing is suspended, and the photoresist is cooled. 50 times of etching and passivation alternate processing; this cycle alternates until the remaining thickness of the etched part of the silicon wafer is less than 150um; the verticality and smoothness of the etched side wall are as follows figure 2 Shown; process chamber pressure of inductively coupled plasma etching machine: 40...

Embodiment 2

[0040] Embodiment 2, comprising:

[0041] (1) Preparation of photoresist pattern steps:

[0042] Evenly coat photoresist on a 2-inch silicon wafer with a thickness of 250 μm, and the thickness of the photoresist is 15 μm; use photolithography to prepare the required pattern on the photoresist;

[0043] (2) Etching steps:

[0044] Using the Bosch process, in the Oxford Plasmalab ICP inductively coupled plasma etching machine of Oxford Instruments, after 40 alternate etching and passivation processes on the silicon wafers prepared for the pattern, the processing was suspended, and after the photoresist cooled, another 40 times were performed. The secondary etching and passivation are alternately processed; this cycle alternates until the remaining thickness of the etched part of the silicon wafer is less than 150um; the process chamber pressure of the inductively coupled plasma etching machine: 40mtorr, the temperature: 10°C;

[0045] In each alternate process of etching and p...

Embodiment 3

[0054] Embodiment 3, comprising:

[0055] (1) Preparation of photoresist pattern steps:

[0056] Uniformly coat photoresist on a 4-inch silicon wafer with a thickness of 250 μm, and the thickness of the photoresist is 15 μm; use a photolithography process and a karl suss MA6 photolithography machine to prepare the required pattern on the photoresist;

[0057] (2) Etching steps:

[0058] Using the Bosch process, in the Oxford Plasmalab ICP inductively coupled plasma etching machine of Oxford Instruments, after 80 times of etching and passivation alternately processed the patterned silicon wafer, the processing was suspended, and after the photoresist cooled down, another 80 times were performed. The secondary etching and passivation are alternately processed; this cycle alternates until the remaining thickness of the etched part of the silicon wafer is less than 150um; the verticality and smoothness of the etched sidewall are as follows figure 2 Shown; process chamber pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com