Process and equipment for purifying dilute acetic acid solution

A technology of solution purification and dilute acetic acid, applied in the field of purification technology, can solve problems such as unsatisfactory treatment effect and secondary pollution, and achieve the effects of shortening the solvent recovery process, reducing steam consumption and reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

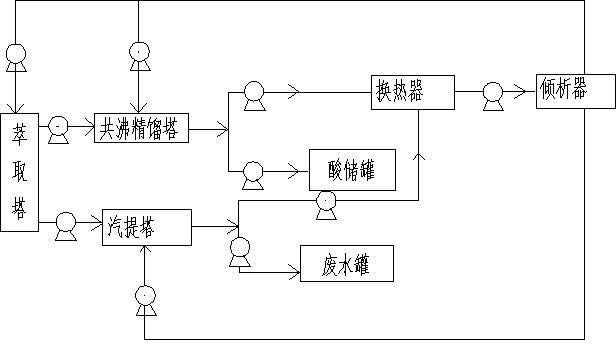

Image

Examples

Embodiment 1

[0025] A kind of dilute acetic acid solution purification technique, described dilute acetic acid solution is the acetic acid solution that massfraction is 6%, and described technique comprises the following steps:

[0026] (1) Extraction: Dilute acetic acid solution enters the upper part of the extraction tower, and the organic phase isopropyl acetate from the decanter enters the lower part of the extraction tower as an extraction agent. In the extraction tower, the extraction agent extracts the acetic acid in the dilute acetic acid solution to in the extraction phase;

[0027] (2) Phase separation: After extraction, the raffinate phase water contains a small amount of isopropyl acetate, which is pumped into the stripping tower; the extract phase containing a small amount of water is pumped into the azeotropic distillation tower; The top temperature is controlled at 98°C, the temperature of the tower is controlled at 100°C and normal pressure, the water obtained from the towe...

Embodiment 2

[0033] A kind of dilute acetic acid solution purification technique, described dilute acetic acid solution is the acetic acid solution that massfraction is 5%, and described technique comprises the following steps:

[0034] (1) Extraction: Dilute acetic acid solution enters the upper part of the extraction tower, and the organic phase isopropyl acetate from the decanter enters the lower part of the extraction tower as an extraction agent. In the extraction tower, the extraction agent extracts the acetic acid in the dilute acetic acid solution to in the extraction phase;

[0035] (2) Phase separation: After extraction, the raffinate phase water contains a small amount of isopropyl acetate, which is pumped into the stripping tower; the extract phase containing a small amount of water is pumped into the azeotropic distillation tower; The top temperature is controlled at 98.6°C, the tower temperature is controlled at 100.3°C and normal pressure, the water obtained from the tower i...

Embodiment 3

[0041] A kind of dilute acetic acid solution purification technique, described dilute acetic acid solution is the acetic acid solution that massfraction is 4%, and described technique comprises the following steps:

[0042] (1) Extraction: The dilute acetic acid solution enters the upper part of the extraction tower, and the organic phase isopropyl acetate from the decanter enters the lower part of the extraction tower as an extraction agent. In the extraction tower, the extraction agent extracts the acetic acid in the dilute acetic acid solution to in the extraction phase;

[0043](2) Phase separation: After extraction, the raffinate phase water contains a small amount of isopropyl acetate, which is pumped into the stripping tower; the extract phase containing a small amount of water is pumped into the azeotropic distillation tower; The top temperature is controlled at 99°C, the tower temperature is controlled at 100.5°C and normal pressure, the water obtained from the tower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com