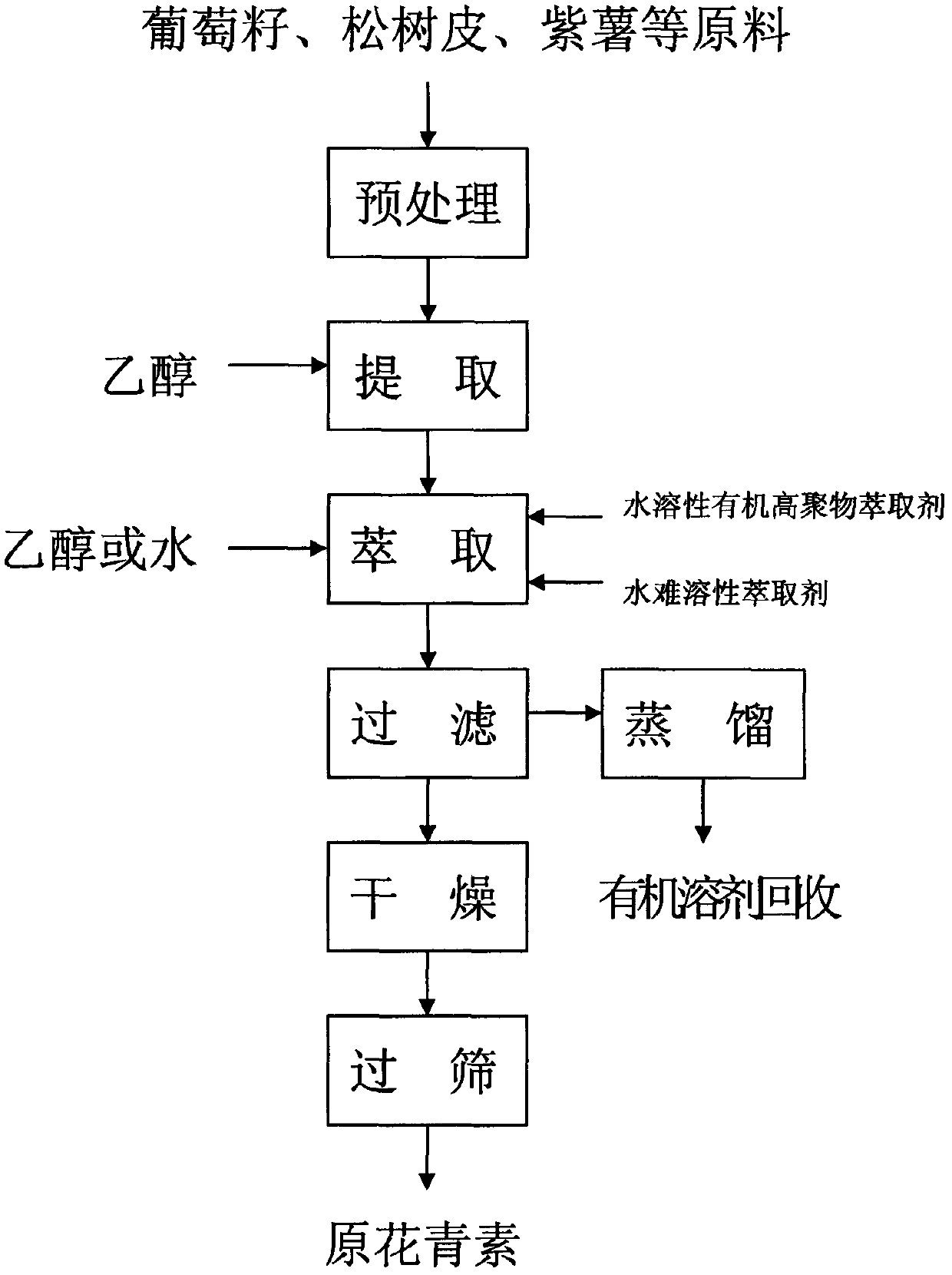

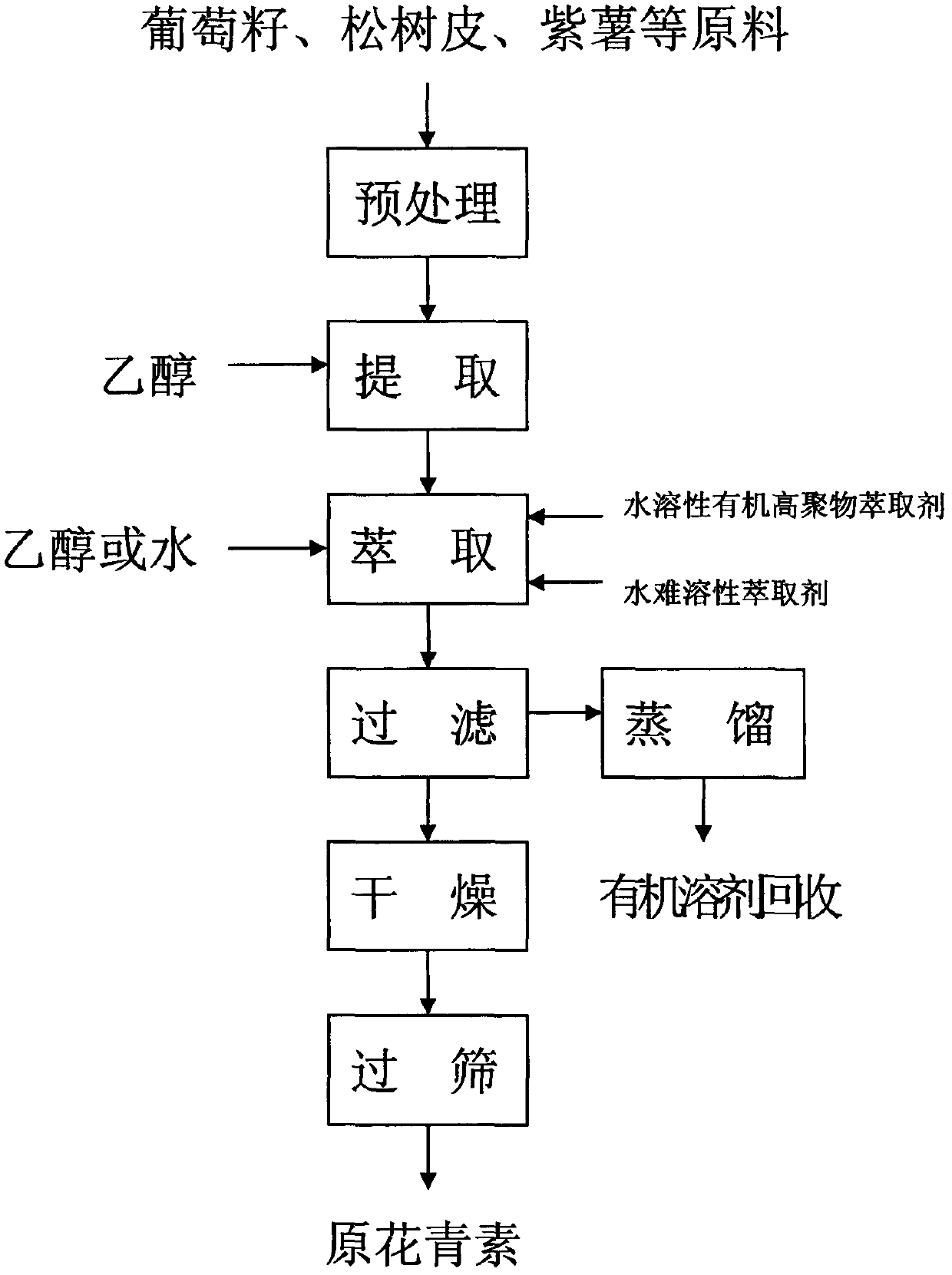

Preparation method of proanthocyanidin

A proanthocyanidin and raw material technology, applied in the field of proanthocyanidin preparation, can solve the problems of inability to carry out large-scale industrial production and immature process, and achieve the effects of easy continuous production operation, short process flow and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 5 parts by weight of proanthocyanidin raw materials that have been removed, coarsely crushed or cut into sections into a stainless steel reaction tank, add the raw materials and 70% ethanol in a ratio of 1:3 by weight, heat and keep warm for extraction three times, and control the temperature at 50-60°C. The incubation time is 1.2h, and the extracts are combined. Add the extract to a stainless steel reaction kettle, add 2% polyacrylic acid and water or ethanol to the extract, adjust the ethanol content to 30-40% of the solution, stir evenly, let stand for 1.5h to form two phases, and obtain the upper phase extraction liquid, add 4 parts by weight (5:1, v / v) of two-phase extractant ethyl acetate-petroleum ether that is insoluble in water and water-soluble to extract, separate the extract, and distill the filtrate to reclaim the organic solvent, and finally control the temperature to be 60 Below ℃, the vacuum degree is above 0.08Mpa to carry out vacuum drying to obtai...

Embodiment 2

[0041] Add 5 parts by weight of proanthocyanidin raw materials that have been removed, coarsely crushed or cut into sections into a stainless steel reaction tank, add the raw materials and 70% ethanol in a ratio of 1:3 by weight, heat and keep warm for extraction three times, and control the temperature at 50-60°C. The incubation time is 1.2h, and the extracts are combined. Then add the extract of the extract into the enamel reaction kettle, add the extract 3% methyl polypropylene glycol and water or ethanol, adjust the ethanol content to 30-40% ethanol of the solution, stir evenly, and let it stand for 1h to form two phases , to obtain the upper phase extract, add water-insoluble and water-soluble two-phase extractant ethyl acetate-petroleum ether 4 parts by weight (5: 1, v / v) for extraction, separate the extract, distill the filtrate to reclaim the organic solvent, and finally The temperature is controlled below 60°C, and the vacuum degree is above 0.08Mpa for vacuum drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com