Method for preparing fluorine-silicon containing polyurethane and acrylate emulsion

A technology of acrylate and polyurethane, applied in the field of preparation of water-based polyurethane, can solve the problems of poor hydrolysis resistance, poor pollution resistance, etc., and achieve the effects of low surface energy, good hydrophobicity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

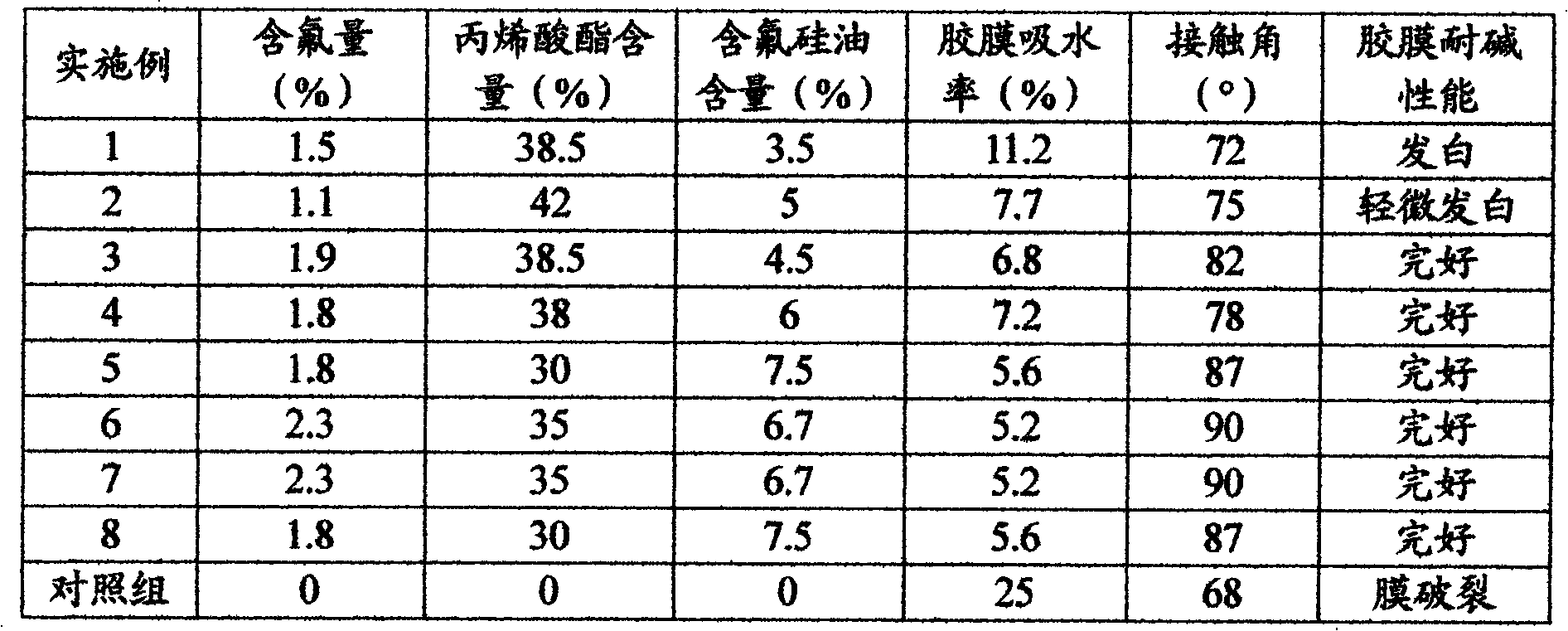

Examples

preparation example Construction

[0013] The preparation method of this fluorine-containing silicon polyurethane-acrylate emulsion comprises the following steps:

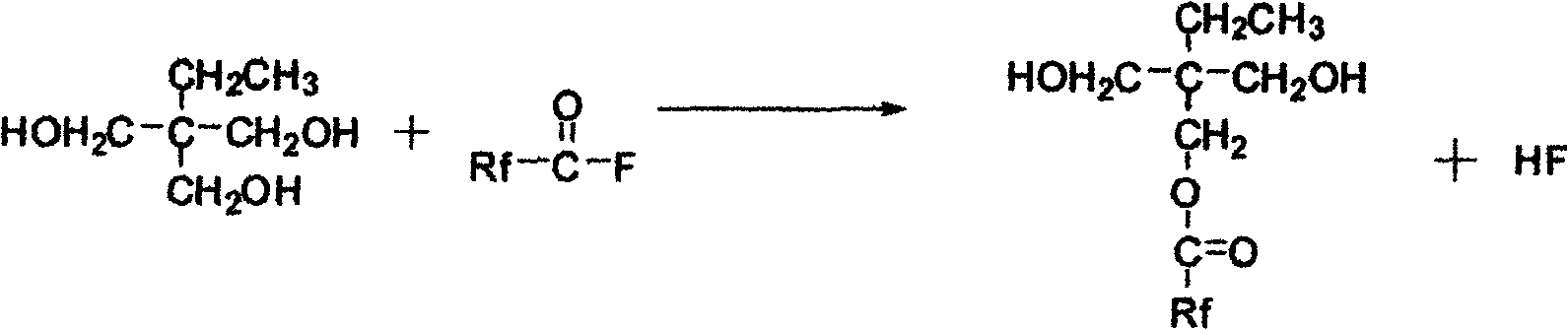

[0014] (1) Under the protection of nitrogen, add acid fluoride dropwise to the ether solution of trimethylolpropane, reflux for 6 to 8 hours, wash with water, and distill under reduced pressure to remove residual water and unreacted raw materials to obtain fluorine-containing bismuth Alcohol; its reaction formula is as follows:

[0015]

[0016] where Rf is -C 7 f 15 、-C 2 f 5 or -CF(CF 3 ) (OCF 2 CF(CF 3 )) m OCF 2 CF 2 CF 3 , m is an integer of 0-3.

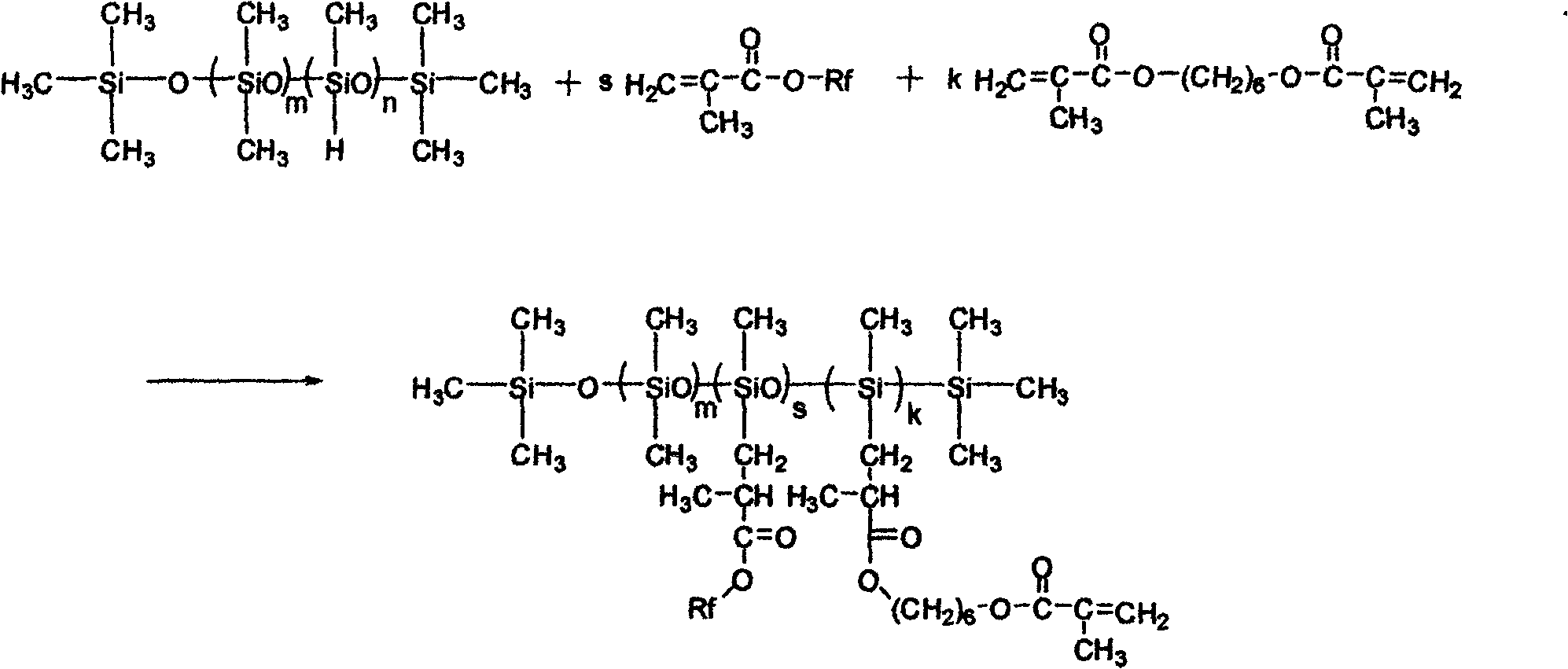

[0017] (2) Use a three-necked flask device with a reflux condenser and a constant pressure funnel, add the toluene solution of hydrogen-containing silicone oil to the constant pressure funnel, add fluorine-containing acrylate, dienyl acrylate and anhydrous Ethanol (absolute ethanol only acts as a cocatalyst), stir and mix evenly, control the temperature at 60-100°C, add Pt catalyst, sl...

Embodiment 1

[0034] 1) Preparation of fluorine-containing diols

[0035]Add 26.8g of trimethylolpropane and 50ml of anhydrous ether to a three-necked flask equipped with a reflux condenser and a constant pressure funnel, and add 89.5g of perfluoro 2,5-dimethyl-3,6 - Dioxononanoyl fluoride, reflux reaction for 6 hours, washed with water, and distilled off under reduced pressure to remove residual water and unreacted raw materials to obtain 102.5 g of fluorine-containing dihydric alcohol. Wherein, the molar ratio of trimethylolpropane to perfluoro 2,5-dimethyl-3,6-dioxononanoyl fluoride is 0.9.

[0036] 2) Preparation of fluorine-containing silicone oil

[0037] In a three-necked flask equipped with a reflux condenser and a constant pressure funnel (pumping and baking 3 times), add 20ml of a toluene solution of 18.5g of hydrogen-containing silicone oil to the constant pressure funnel; add 4.5g of methacrylic acid deca Difluoroheptyl ester, 1.2 g of dipropylene glycol diacrylate and 2 g of ...

Embodiment 2

[0047] 1) Preparation of fluorine-containing diols

[0048] Add 26.8g of trimethylolpropane and 50ml of anhydrous ether to a three-necked flask equipped with a reflux condenser and a constant pressure funnel, and add 89.5g of perfluoro 2,5-dimethyl-3,6 - Dioxononanoyl fluoride, reflux reaction for 6 hours, washed with water, and distilled off under reduced pressure to remove residual water and unreacted raw materials to obtain 102.5 g of fluorine-containing dihydric alcohol. Wherein, the molar ratio of trimethylolpropane to perfluoro 2,5-dimethyl-3,6-dioxononanoyl fluoride is 0.9.

[0049] 2) Preparation of fluorine-containing silicone oil

[0050] In a three-necked flask equipped with a reflux condenser and a constant pressure funnel (pumping and baking 3 times), add 20ml of a toluene solution of 18.5 hydrogen-containing silicone oil to the constant pressure funnel; add 4.5g of hexafluoromethacrylate to the three-necked flask Butyl ester, 3.2g dipropylene glycol diacrylate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com