Heavy metal sludge recycling and innocent treatment method

A heavy metal sludge and treatment method technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of resource utilization and harmless treatment, etc. Achieve good economic and social benefits, high metal recovery rate, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

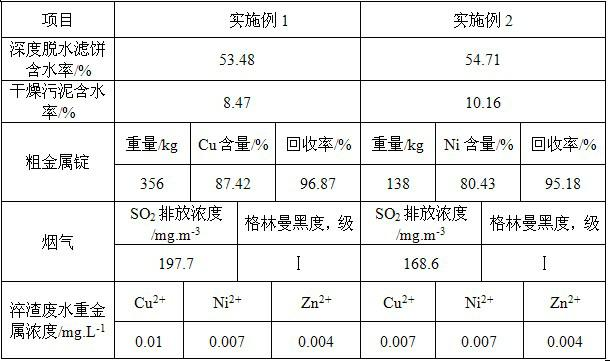

[0021] Example 1: Composition of copper sludge: Cu 3.07%, Fe 1.34%, Si 1.44%, Ca 1.05%, Al 0.70%, Zn 0.09%, S 0.31%, Ni<0.01%, moisture 82.51%, others 9.48%.

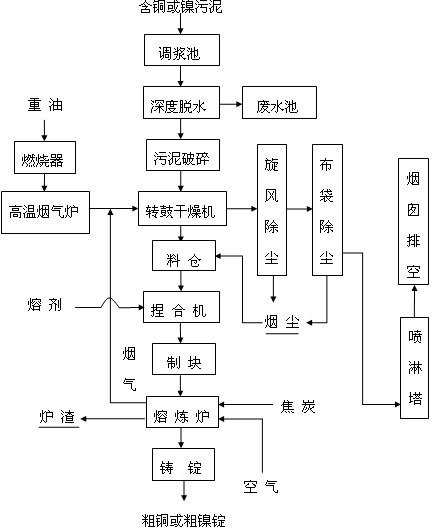

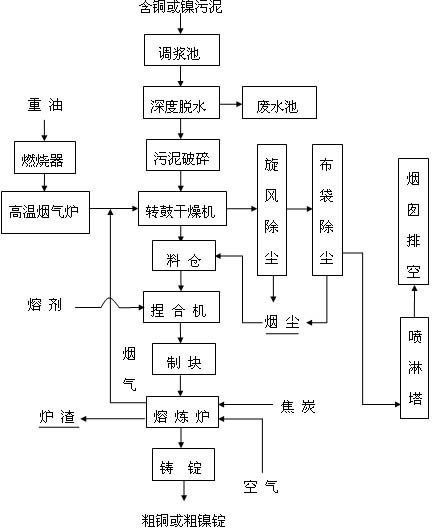

[0022] The treatment method sequentially includes five steps: deep sludge dehydration, crushing and drying, batching and block making, smelting and flue gas treatment.

[0023] (1) Deep dehydration of sludge.

[0024] Put the copper sludge with the above components into the sludge mixing tank, add water to prepare a slurry with a water content of 94%, and then use a diaphragm pump to feed and filter for 90 minutes. The feed pressure is controlled at 0.8MPa. After the feed is filtered , switch to a screw pump with a water inlet pressure of 1.6MPa to feed water to the diaphragm filter plate, and press and dehydrate the filter cake for 40 minutes to obtain a deeply dehydrated filter cake.

[0025] The waste water generated in the deep dehydration process is purified and treated up to the standard, and then used as cooli...

Embodiment 2

[0034] Example 2: Composition of nickel sludge: Ni 1.03%, Fe 1.47%, Cu 0.16%, Si 1.58%, Ca 0.92%, Al 0.77%, Zn 0.24%, S 0.36%, moisture 84.14%, others 9.33% .

[0035] The treatment method sequentially includes five steps: deep sludge dehydration, crushing and drying, batching and block making, smelting and flue gas treatment.

[0036] (1) Deep dehydration of sludge.

[0037] Put the nickel sludge with the above components into the sludge mixing tank, add water to prepare a slurry with a water content of 92%, and then use a diaphragm pump to feed and filter for 80 minutes, and the feed pressure is controlled at 0.8MPa. After the feed is filtered , switch to a screw pump with a water inlet pressure of 1.6MPa to feed water to the diaphragm filter plate, and press and dehydrate the filter cake for 30 minutes to obtain a deeply dehydrated filter cake.

[0038] The waste water generated in the deep dehydration process is purified and treated up to the standard, and then used as c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com