Preparation method of hard alloy with double crystal structure

A technology of cemented carbide and double crystal structure, which is applied in the field of cemented carbide materials, can solve the problems of limited application range and inability to meet the comprehensive performance of products, and achieve the effects of improving hardness, good impact toughness and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

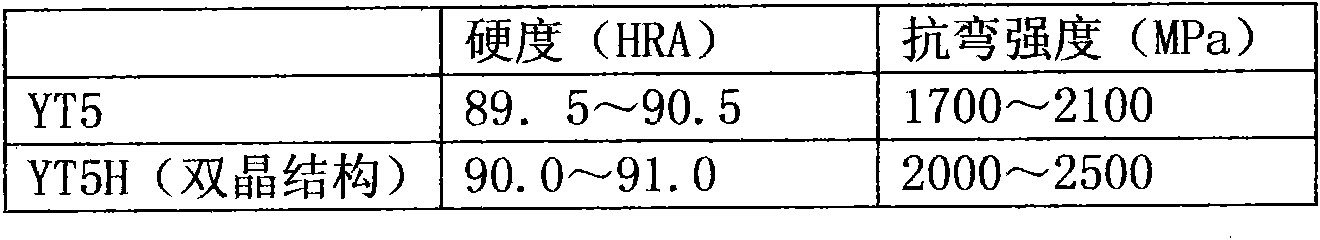

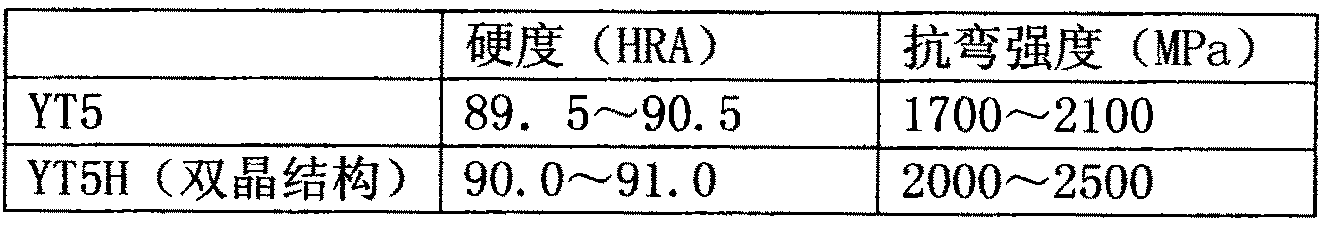

[0012] refer to figure 1 , the specific embodiment adopts the following technical scheme: its formula consists of: coarse particle tungsten carbide (WC), fine particle tungsten carbide; its preparation method is: 1, coarse particle and fine particle tungsten carbide are mixed according to 3:7~ 7:3 ratio is added in the mixture; 2, pre-ball milling: the weight percentage is 9~11% cobalt powder and weight percentage is 4.56% titanium element and fine particle tungsten carbide are packed in ball mill, add the weight percentage prepared in advance to be 2-2.5% paraffin wax powder and 0.5-1.5ml oleic acid per kilogram of mixture as dispersant, 300-380ml of alcohol per kilogram of mixture as mixture medium; alloy balls for grinding are loaded 3-4 times as much as the mixture In the ball mill; titanium element is added in the form of WC (TiC) solid solution; pre-milling for 20-30 hours; 3. Secondary charging ball milling: put coarse tungsten carbide powder and cobalt powder into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com