Method for preparing transition metal phosphide Fe2P

A technology of transition metals and phosphides, applied in the direction of phosphides, etc., to achieve the effect of novel synthesis method, simplified preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Weigh 0.467 g FePO 4 and 0.20 g KBH 4 , mix well in a mortar;

[0020] 2. React the mixture under the protection of argon at 520°C for 30min; grind the obtained product finely, wash with distilled water and absolute ethanol three times respectively, and then vacuum dry at 60°C for 12h to obtain the product Fe 2 p.

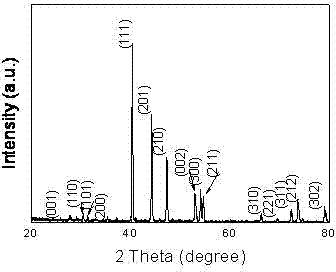

[0021] figure 1 is the XRD pattern of the obtained material. Compared with the standard card, it can be seen that the synthetic material is the standard Fe 2 p.

Embodiment 2

[0023] 1. Weigh 0.467 g FePO 4 and 0.25 g NaBH 4 , mix well in a mortar;

[0024] 2. React the mixture under the protection of argon at 600°C for 30min; grind the obtained product into fine powder, wash with distilled water and absolute ethanol three times respectively, and then vacuum-dry at 60°C for 12h to obtain the product Fe 2 p.

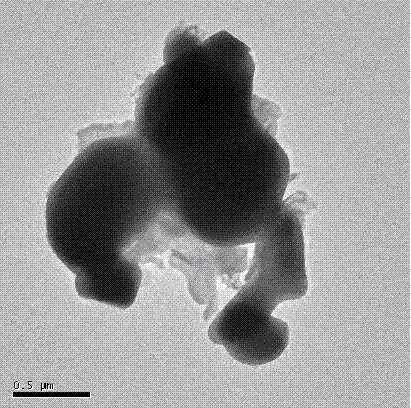

[0025] figure 2 For the prepared Fe 2 TEM image of P. It can be seen from the figure that the Fe 2 P is a spherical particle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com