Low-temperature foaming phenolic resin, preparation method thereof and preparation method of modified phenolic foam

A technology of foaming phenolic resin and low temperature, which is applied in the field of modified phenolic foam, which can solve problems such as environmental pollution and difficult production control, and achieve the effects of stable process, beautiful appearance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

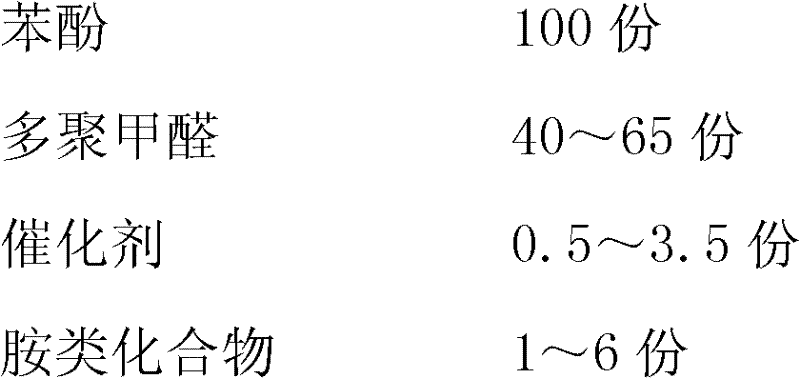

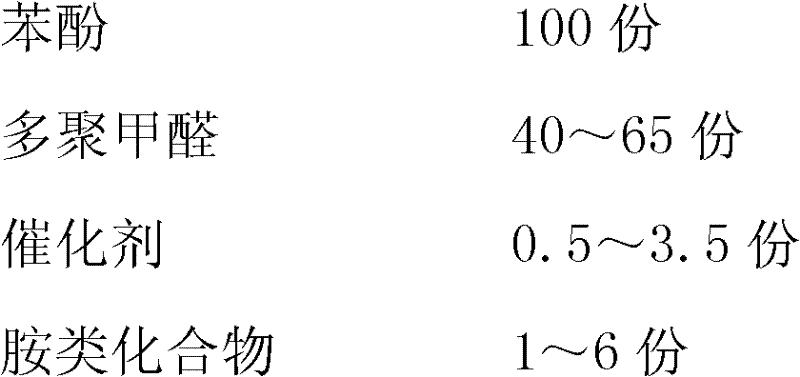

[0026] (1) Preparation of low-temperature foaming phenolic resin

[0027] Add 800 kilograms of phenol and 15 kilograms of 30% (weight percent) sodium hydroxide into a 2 ton reaction kettle, stir, heat to 80°C, add 320 kilograms of paraformaldehyde in 6 times, react for 30 minutes, and heat up to 90~ React at 95°C for 30 minutes, then lower the temperature to 85°C, add 10 kg of urea, react for 50 minutes, and lower the temperature to room temperature to obtain a low-temperature foaming phenolic resin with a viscosity of 2000CP / 25°C.

[0028] (2) Preparation of modified phenolic foam

[0029] Combine 100 parts of low-temperature foaming phenolic resin prepared in (1) (parts by weight, the same below) and 4 parts of Tween 80, 6 parts of petroleum ether, 3 parts of ethanol, 3 parts of modified rubber powder, stir well and add 9 parts Benzene sulfonic acid is stirred at room temperature for 20 seconds and then injected into the mold cavity, and cured for 2 minutes to obtain modified phen...

Embodiment 2

[0031] Add 100 parts of low-temperature foaming phenolic resin prepared in (1), H3302 parts of silicone oil, 4 parts of n-pentane, 3 parts of ethanol, and 3 parts of modified rubber powder. After stirring, add 11 parts of benzenesulfonic acid and stir for 2 minutes. After being injected into the cavity for 5 minutes, a modified phenolic foam board and products with excellent curing are obtained.

Embodiment 3

[0033] Add 100 parts of low-temperature foaming phenolic resin prepared in (1), DC-1934 parts of silicone oil, 5 parts of ethanol, 9 parts of n-pentane, and 6 parts of modified rubber powder. After stirring, add 3 parts of xylene sulfonic acid and 7 parts of toluenesulfonic acid, stirred for 5 minutes and injected into the mold cavity for 3 minutes to obtain a modified phenolic foam board and products with excellent curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com