Sn-Zn alloy electroplating solution

An alloy electroplating solution, sn-zn technology, applied in the field of electroplating solution, can solve problems such as increased electroplating costs, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

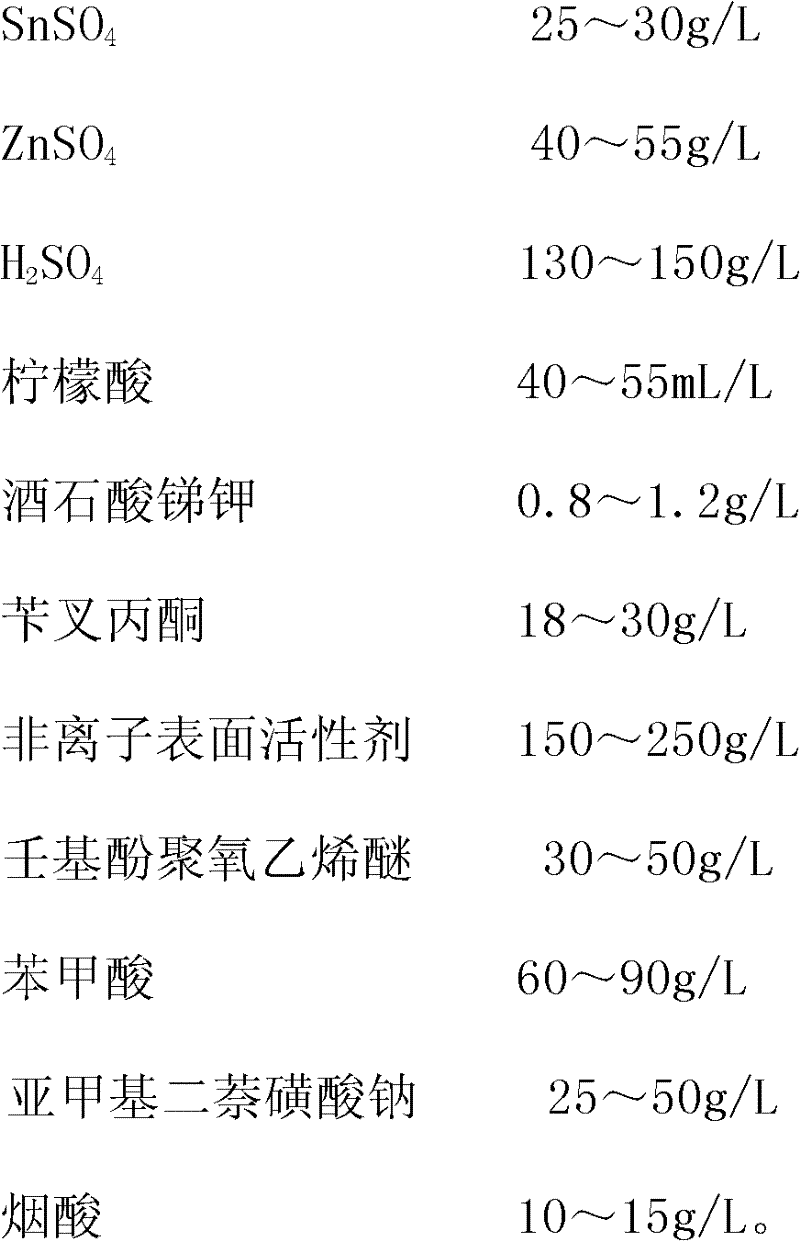

[0022] A kind of Sn-Zn alloy electroplating solution, its material and composition are as follows:

[0023] SnSO 4 26g / L

[0024] ZnSO 4 45g / L

[0025] h 2 SO 4 140g / L

[0026] Citric acid 40mL / L

[0027] Antimony Potassium Tartrate 0.9g / L

[0028] Benzylidene acetone 20g / L

[0029] Non-ionic surfactant 200g / L

[0030] Nonylphenol polyoxyethylene ether 30g / L

[0031] Benzoic acid 70g / L

[0032] Sodium methylene dinaphthalene sulfonate 25g / L

[0033] Niacin 11g / L

[0034] The above materials are mixed evenly in proportion; the anode required for the electroplating of the Sn-Zn alloy electroplating solution is tin with a purity of 99.9%; the current density of the Sn-Zn alloy electroplating solution is 2~4A / dm 2 ; The temperature of the Sn-Zn alloy electroplating solution is 15-30°C. After the plated parts are electroplated by the above-mentioned Sn-Zn alloy electroplating solution, a fine crystal and good decorative brig...

Embodiment 2

[0036] A kind of Sn-Zn alloy electroplating solution, its material and composition are as follows:

[0037] SnSO 4 30g / L

[0038] ZnSO 4 55g / L

[0039] h 2 SO 4 145g / L

[0040] Citric acid 55mL / L

[0041] Antimony Potassium Tartrate 1.2g / L

[0042] Benzylidene acetone 28g / L

[0043] Non-ionic surfactant 250g / L

[0044] Nonylphenol polyoxyethylene ether 50g / L

[0045] Benzoic acid 89g / L

[0046] Sodium methylene dinaphthalene sulfonate 48g / L

[0047] Niacin 14 g / L

[0048] Configure according to the above ratio and stir evenly; the required anode is tin with 99.9% purity during the electroplating of the Sn-Zn alloy electroplating solution; the current density of the Sn-Zn alloy electroplating solution is 2~4A / dm 2 ; The temperature of the Sn-Zn alloy electroplating solution is 15-30°C. After the plated parts are electroplated by the above-mentioned Sn-Zn alloy electroplating solution, a fine crystal and good decorative b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com