Method for preparing polyaniline composite nano silver conductive fibers

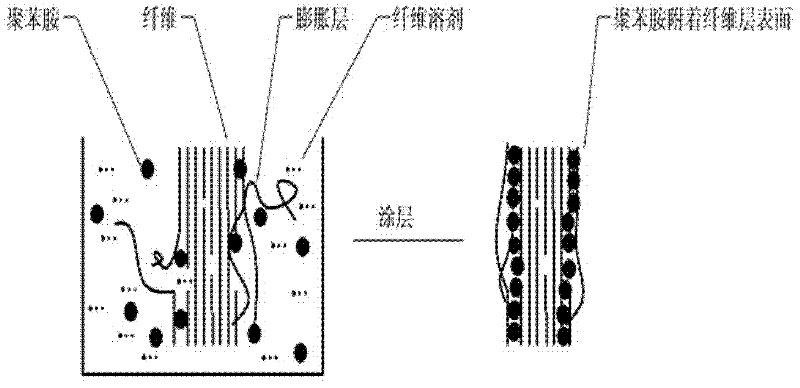

A technology of conductive fiber and polyaniline, which is applied in fiber type, fiber treatment, textile and papermaking, etc., can solve the problems of washing resistance, poor spinning performance, high price, etc., and achieve improved conductive durability and good conductive durability , Improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Preparation of conductive coating solution

[0028] The polyaniline particles pulverized by a mortar and a formic acid solution with a mass fraction of 60% were prepared into a conductive coating solution.

[0029] 2) Preparation of coated conductive fibers

[0030] The conductive coating solution was coated on the surface of PA6 fiber with a roller fiber coating machine at a winding speed of 50 r / min, and then washed and dried to obtain PANI / PA6 coated conductive fiber A. The temperature of the evaporation tube was controlled at 80 °C.

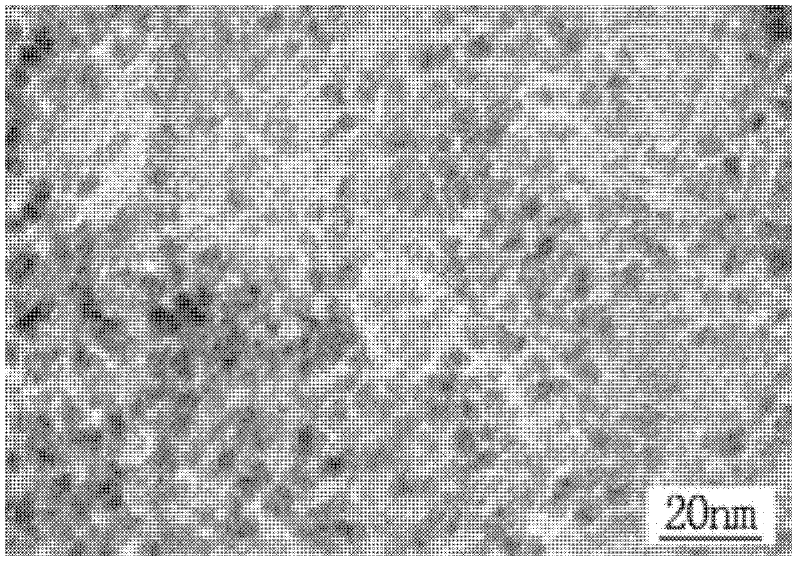

[0031] 3) In situ synthesis of nano silver-polyaniline layer

[0032] The conductive fiber A was mixed with silver nitrate (AgNO 3 ) in aqueous solution for 0.5h, and then immersed in NaBH with a concentration of 0.2mol / L 4 In an aqueous solution, react at room temperature for 6 hours, and finally wash with ethanol and deionized water respectively, and dry naturally or dry to obtain polyaniline / nano-silver composite conductive f...

Embodiment 2

[0035] 1) Preparation of conductive coating solution

[0036] The polyaniline particles pulverized by a mortar and a formic acid solution with a mass fraction of 65% were prepared into a conductive coating solution.

[0037] 2) Preparation of coated conductive fibers

[0038] The conductive coating solution was coated on the surface of PA6 fiber with a roller fiber coating machine at a winding speed of 100r / min, and then washed and dried to obtain PANI / PA6 coated conductive fiber A. The temperature of the evaporation tube was controlled at 100°C.

[0039] 3) In situ synthesis of nano silver-polyaniline layer

[0040] The conductive fiber A was mixed with silver nitrate (AgNO 3 ) in aqueous solution for 0.75h, and then immersed in NaBH with a concentration of 0.5mol / L 4 In an aqueous solution, react at room temperature for 7 hours, and finally wash with ethanol and deionized water respectively, and dry naturally or dry to obtain polyaniline / nano-silver composite conductive ...

Embodiment 3~5

[0042] Embodiment 3~5: preparation method is the same as embodiment 1~2, changes each processing condition, and the results are shown in Table 1:

[0043] Table 1

[0044] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com