Method for preparing nano-gap electrodes on surface of nano-pore and in nano-pore

A nano-gap electrode and nano-gap technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve the problem of not being able to reach a single nucleotide, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

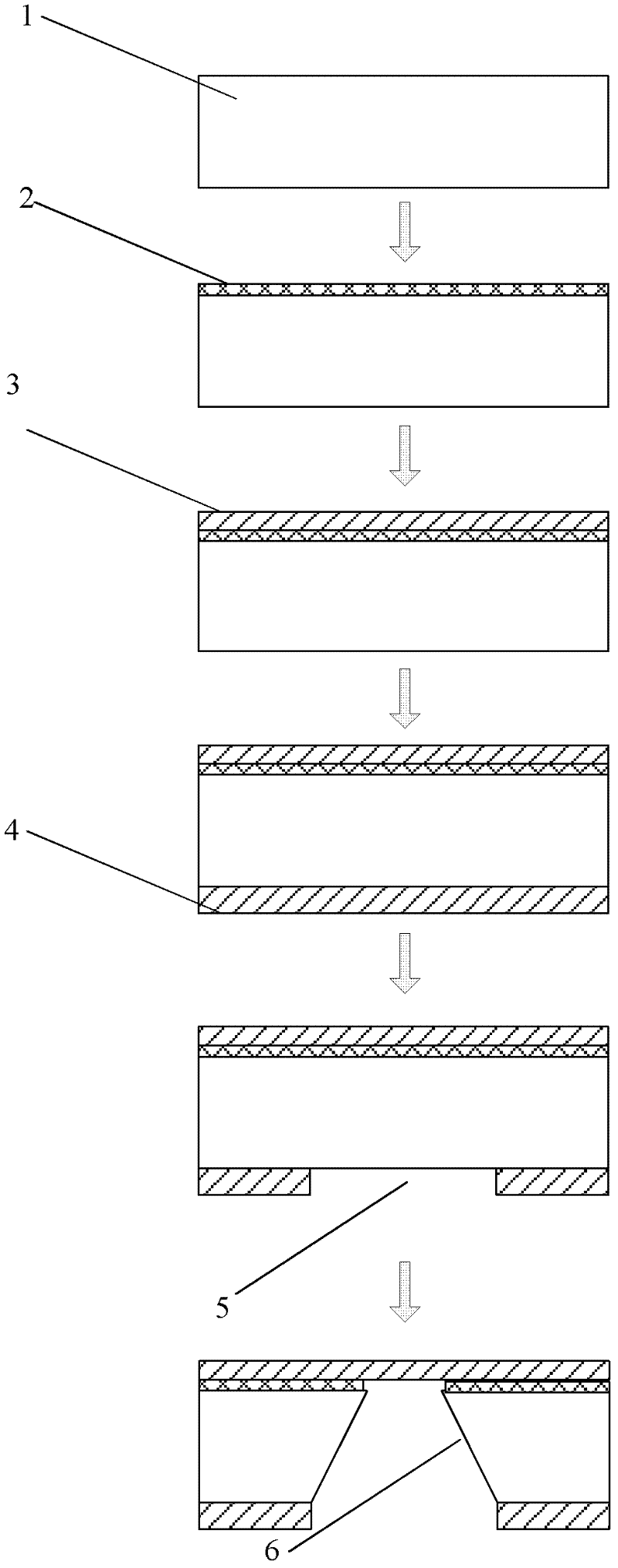

[0030]On the front silicon nitride film, the desired metal line pattern is formed on the photoresist by ultraviolet lithography, and then the metal line pattern 7 is evaporated using an electron beam evaporation apparatus. Finally, at the position of the metal wire of the etching window, a nano-gap 8 is etched on the metal wire by using focused electron beam etching, and then a nano-hole 9 is etched to form a surface nano-gap electrode at the opening of the nano-hole.

Embodiment 2

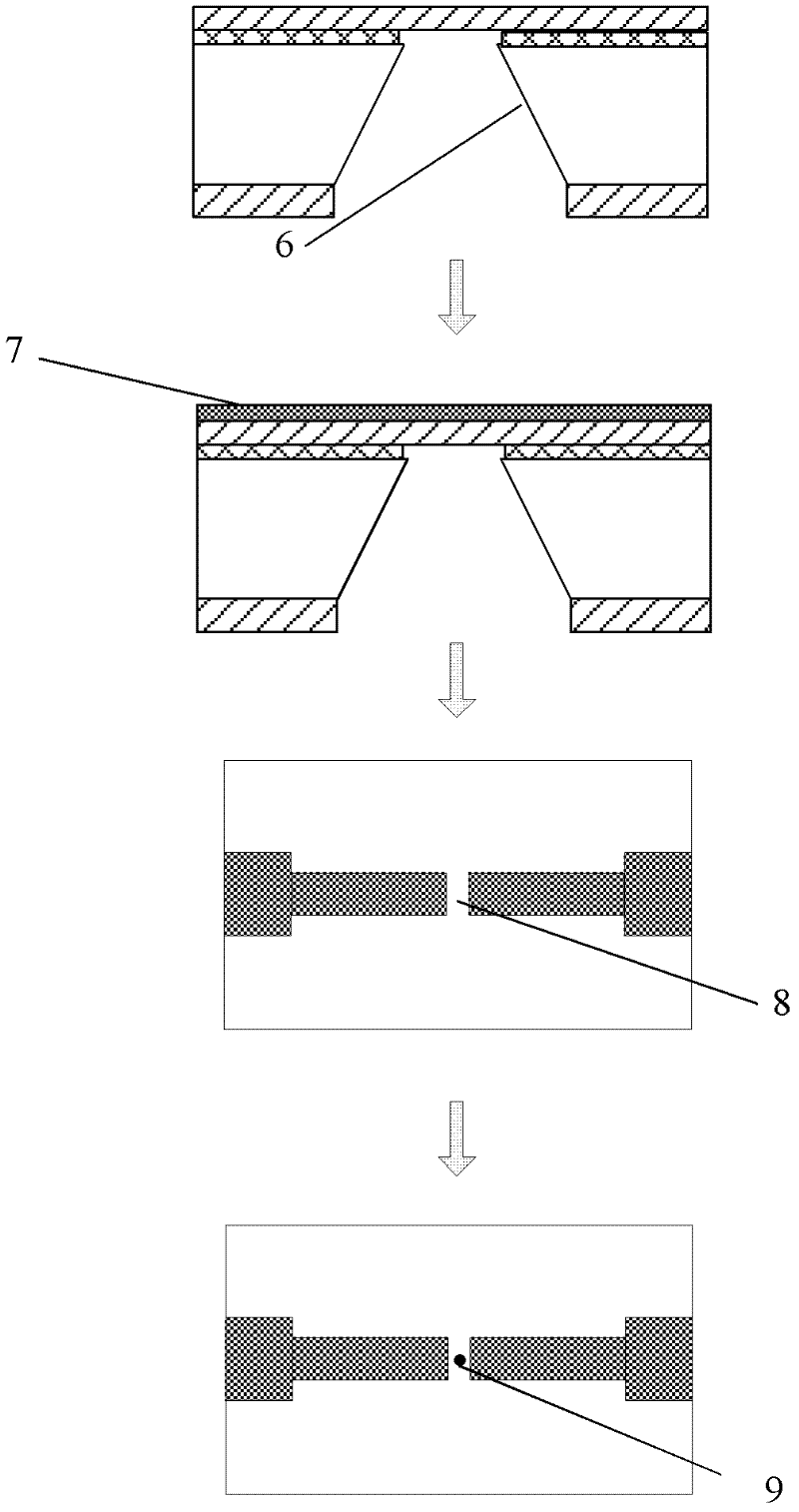

[0032] On the front silicon nitride film, the desired metal line pattern is formed on the photoresist by ultraviolet lithography, and then the metal line pattern 7 is evaporated using an electron beam evaporation apparatus. Finally, at the position of the metal wire in the etching window, use a focused electron beam to etch a metal wire with a line width of microns into a nanowire 10, and then use a focused ion beam or a high-energy electron beam to etch a nanometer-sized hole 11 , the metal nanowire is etched just to form a surface nano-gap electrode at the nanohole orifice. The surface nano-gap electrodes prepared by this method can control the spacing within the range of 10-50nm. The spacing of the nano-gap electrodes formed by this method of just etching off the nano-metal wires when etching the nano-pores will be slightly larger than the aperture of the nano-pores. image 3 The picture is too small to show it in detail.

Embodiment 3

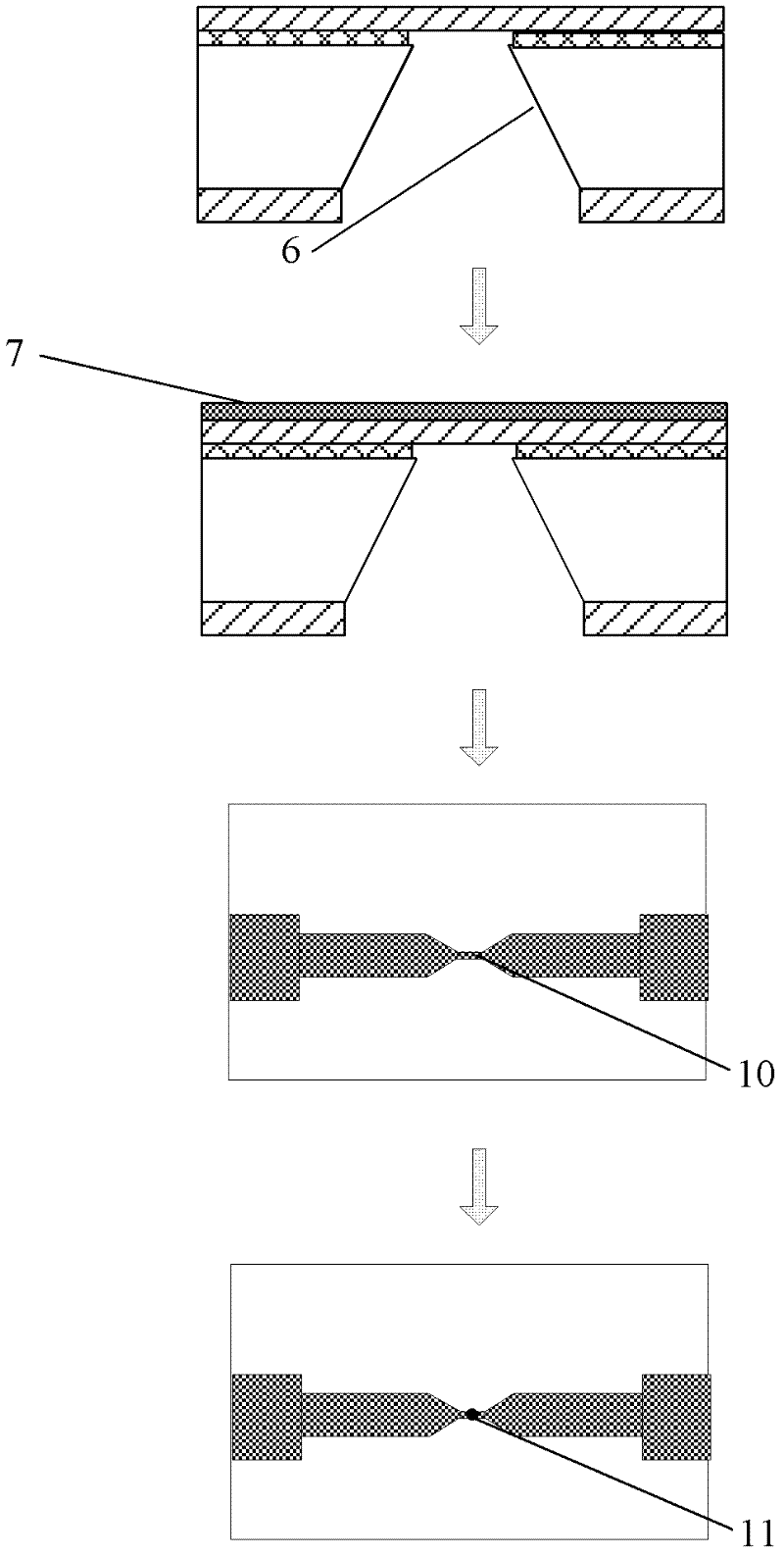

[0034] On the basis of Example 2, the Pt lines are deposited on the surface of the nanogap electrode 12 by using the focused ion beam induced deposition method. The width of the Pt line is set between 5-50nm, the length depends on the distance from the nano-electrode etched by FIB to the edge of the nano-hole, and the thickness is between a few nanometers and tens of nanometers. Select an accelerating voltage of 30kV, select different ion beams to deposit Pt lines, first select one of the electrodes to induce the deposition of Pt lines 13 on one side, stop deposition when the Pt line is close to the edge of the hole, and then start from the other electrode Deposit the Pt line 14 on the other side, and stop the deposition when the Pt line is close to the edge of the hole, and finally form a nanogap electrode with a spacing of 1-10 nm above the nanohole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com