Catalyst for preparing isobutene by methyl tert-butyl ether cracking, preparation method, and application thereof

A technology for methyl tertiary butyl ether and isobutylene, which is applied to a catalyst for preparing isobutylene by cracking methyl tertiary butyl ether and its preparation and application fields, can solve the problem of increasing production cost and efficiency, reducing MTBE conversion rate, affecting isobutylene selectivity, etc. problems, to achieve the effect of saving steps and devices, long operation cycle and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of amorphous silicon aluminum W-1 is as follows: immerse 50g of amorphous silicon aluminum into 100mL Be(NO 3 ) 2 In the aqueous solution, the concentration of the solution is 0.1 mol / L, and after being immersed, it is calcined at 400° C. for 6 hours to obtain amorphous silicon aluminum containing 3 wt% of beryllium oxide.

[0025] The preparation method of amorphous silicon-aluminum W-2 is as follows: immerse 50g of amorphous silicon-aluminum into 100mL Ni(NO 3 ) 2 In the aqueous solution, the concentration of the solution is 0.1 mol / L, and after being immersed, it is calcined at 400° C. for 6 hours to obtain amorphous silicon aluminum containing 0.6 wt% of nickel oxide.

[0026] The preparation of amorphous silicon-aluminum W-3 adopts a step-by-step method: 50g of amorphous silicon-aluminum is immersed in 100mLBe(NO 3 ) 2 In the aqueous solution, the concentration of the solution is 0.1 mol / L, and it is calcined at 400°C for 6 hours after immersion. T...

Embodiment 1

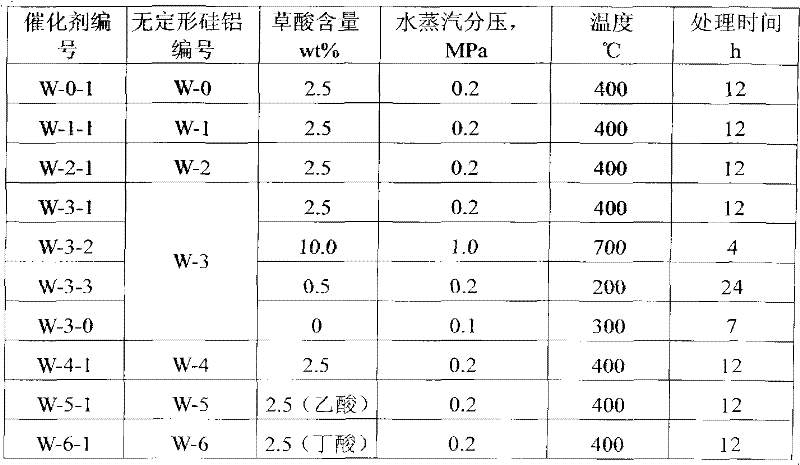

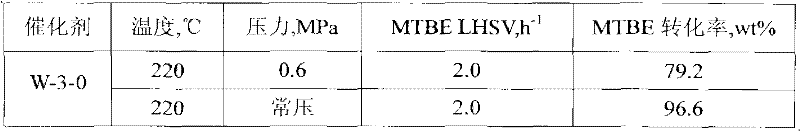

[0037] The high-pressure MTBE cracking test will be carried out through the above-mentioned catalysts (except catalyst W-3-0). The specific test conditions and test results are shown in Table 3.

[0038] table 3

[0039] Catalyst

[0040] Note: The selectivity of methanol and isobutylene are both greater than 99%.

Embodiment 2

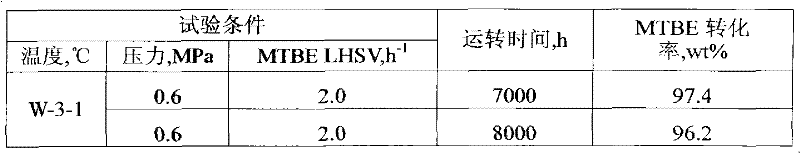

[0045] The life test results of catalyst W-3-1 are shown in Table 5.

[0046] table 5

[0047]

[0048] It can be seen from Table 5 that the activity stability of the catalyst W-3-1 is very good, the activity is basically stable in the first 7000 hours of operation test, and the activity is slightly decreased after 1000 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com