Preparation method of eggshell-type hydrogenation catalyst

A hydrogenation catalyst, eggshell technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems affecting the service life of the catalyst, the low strength of the catalyst, etc., to reduce the pore volume and Loss of specific surface, large pore volume and specific surface area, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

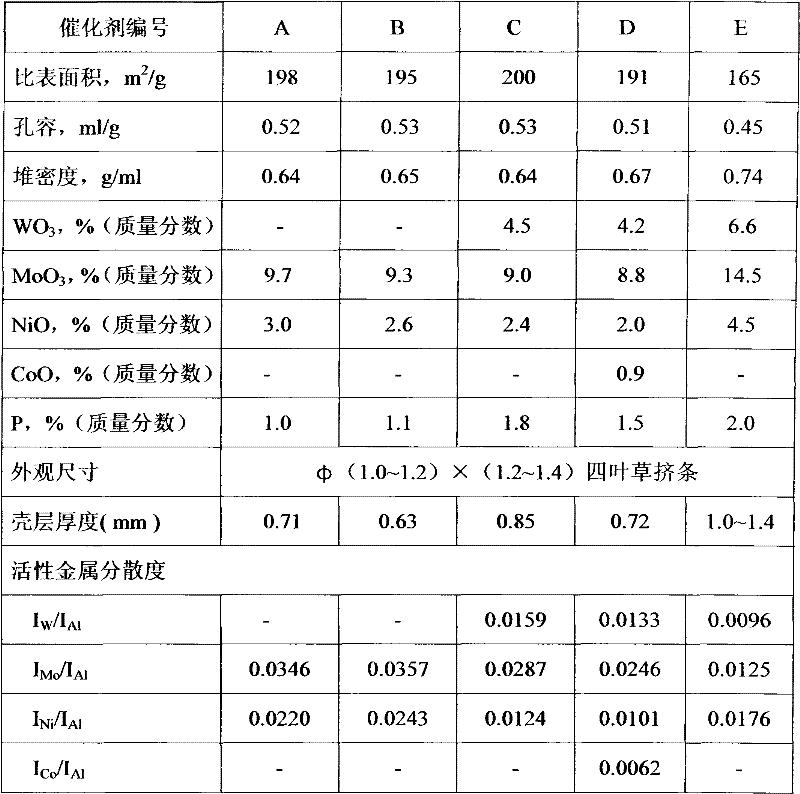

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of carrier

[0026] Take by weighing 300 grams of commercially available pseudo-boehmite powder, add 8 grams of fenugreek powder, 6 grams of carbon black, 4 grams of dilute nitric acid, mix well, add an appropriate amount of deionized water, and knead at room temperature for 30 minutes to form a plastic body. Extrude into four-leaf clover strips on the extruder. Dry the wet strip in a drying oven at 110°C for 4 hours, and keep the temperature at 650°C in a calcination furnace for 4 hours to obtain an alumina carrier.

Embodiment 2

[0027] Embodiment 2: the preparation of catalyst

[0028] Prepare the impregnation solution: add ammonium molybdate, nickel nitrate and phosphoric acid into water to dissolve, then add Tween 20 to adjust the pH value to 4.0, and then add tetradecyltributylammonium chloride to obtain the impregnation solution, in which MoO 3 The content of NiO is 22.1g / 100ml, the content of NiO is 5.3g / 100ml, the content of phosphorus is 2.1g / 100ml, the content of Tween 20 is 4.2g / 100ml, the content of tetradecyltributylammonium chloride is 1.2g / 100ml.

[0029] Weigh 100ml of the impregnating solution, put it into the impregnation tank, heat up to 40°C, then weigh 100 grams of the carrier of Example 1, put it into the impregnation tank, pass in appropriate air for bubbling, take it out after soaking for 2 hours, and Dry at 110°C in the air for 5 hours, and calcinate at 450°C for 4 hours to obtain the finished catalyst, coded as A.

Embodiment 3

[0030] Embodiment 3: the preparation of catalyst

[0031] The method is the same as in Example 2, the pH value of the impregnating solution is 4.5, and the MoO in the impregnating solution 3 The content of NiO is 22.1g / 100ml, the content of NiO is 5.3g / 100ml, the content of phosphorus is 2.1g / 100ml, the content of Tween 40 is 5.0g / 100ml, and the content of octadecyltrimethylammonium bromide is 3.0g / 100ml, the serial number of the obtained catalyst is B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com