Processing method for recycling sodium sulfate from waste alkali liquor in ethylene unit

A technology of ethylene waste lye and sodium sulfate, which is applied in the fields of neutralization, crystallization and recovery of sodium sulfate, and oxidation of ethylene waste lye, which can solve the problems of expensive precipitant, limited lye utilization, and poor precipitation quality , to achieve the effect of reducing salt content, avoiding impact and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

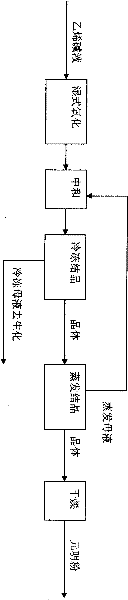

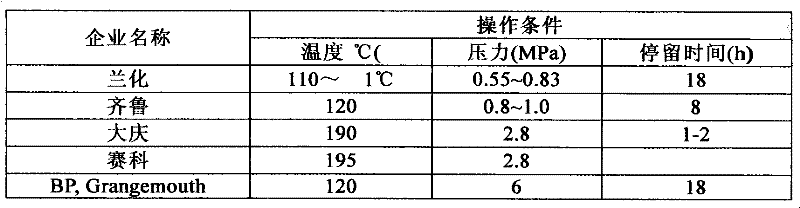

Method used

Image

Examples

Embodiment 1

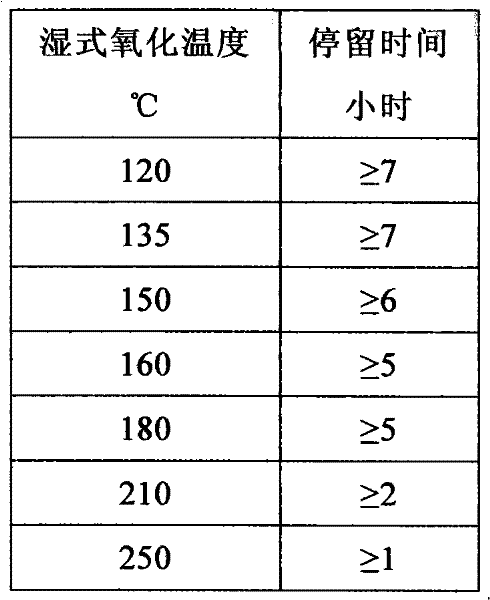

[0048] The ethylene spent lye was oxidized in wet air at 120°C (6MPa) for 8 hours without dilution and pH adjustment, and the resulting oxidation solution was neutralized to pH 5.46 with concentrated sulfuric acid. The neutralized solution was frozen and crystallized, and the frozen mother liquor was removed. Biochemical, frozen crystallization is dried into Yuanming powder after vacuum evaporation and crystallization, and the evaporated mother liquor is returned to the neutralization unit. The sodium sulphate content of the obtained sodium sulfate is 93.76%, which meets the qualified product standard of "GB-T 6009-2003 Industrial Anhydrous Sodium Sulphate" III; L, total dissolved solids 9%.

Embodiment 2

[0050] The ethylene spent lye was subjected to wet oxygen oxidation at 150°C (4.5MPa) for 6h without dilution and pH adjustment, and the resulting oxidized solution was neutralized to pH 5.03 with concentrated sulfuric acid. The neutralized solution was frozen and crystallized, and the mother liquor was frozen. De-biochemical, frozen and crystallized by vacuum evaporation and crystallization, then dried into Yuanming powder, and the evaporated mother liquor is returned to the neutralization unit. The sodium sulfate content of the obtained sodium sulfate is 97.24%, which meets the "GB-T 6009-2003 Industrial Anhydrous Sodium Sulfate" Class II qualified product standard; the amount of the obtained frozen mother liquor is reduced to about 1 / 3 of the neutralization liquid amount, and the COD 900mg / L, total dissolved solids 7%.

Embodiment 3

[0052] The ethylene spent lye was oxidized in wet air at 160°C (6MPa) for 5 hours without dilution and pH adjustment, and the resulting oxidized solution was neutralized to pH 4.64 with concentrated sulfuric acid. Biochemical, frozen crystallization is dried into Yuanming powder after vacuum evaporation and crystallization, and the evaporated mother liquor is returned to the neutralization unit. Gained sodium sulfate sodium sulfate content is 99.05%, meets the "GB-T 6009-2003 Industrial Anhydrous Sodium Sulfate" Class II qualified product standard (because the color turns yellow); the amount of frozen mother liquor of gained is reduced to about 1% of the amount of neutralizing liquid / 3, COD 450mg / L, total dissolved solids 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com