Method for preparing low-carbon olefin by synthetic gas one-step technology

A low-carbon olefin and synthesis gas technology, applied in the direction of hydrocarbon production from carbon oxides, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of low selectivity of low-carbon olefins, low CO conversion rate, etc., to improve Effects of conversion, reduction of surface acidity, and increase in quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The required amount of acid-washed activated alumina carrier is calcined at 1100° C. for 1 hour for later use. A certain amount of ferric nitrate, manganese nitrate and potassium nitrate are dissolved in water to form a mixed solution I with a certain concentration. Under vacuum conditions, impregnate the above mixed solution I on the required amount of treated alumina carrier to obtain the catalyst precursor J. The impregnated catalyst precursor J was dried at 110°C, and then calcined at a temperature of 600°C, and the calcining time was 2 hours, to obtain a catalyst for producing low-carbon olefins by one-step synthesis gas, and its composition was as follows:

[0026] 35% Fe 100 mn 50 K 30 o x +65% Al 2 o 3 .

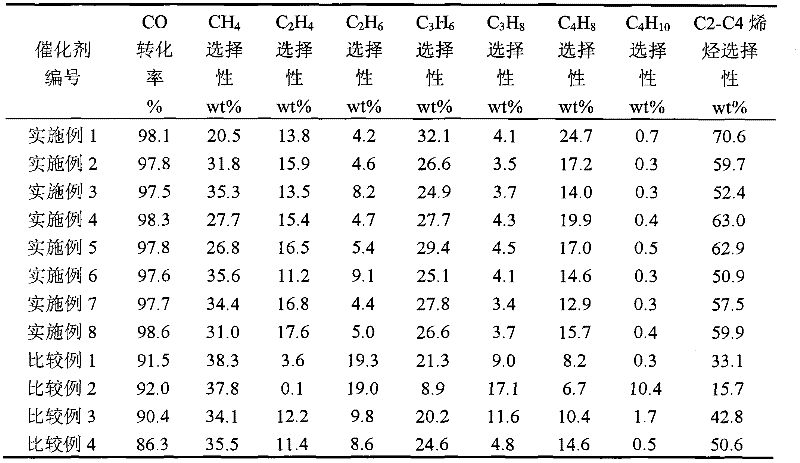

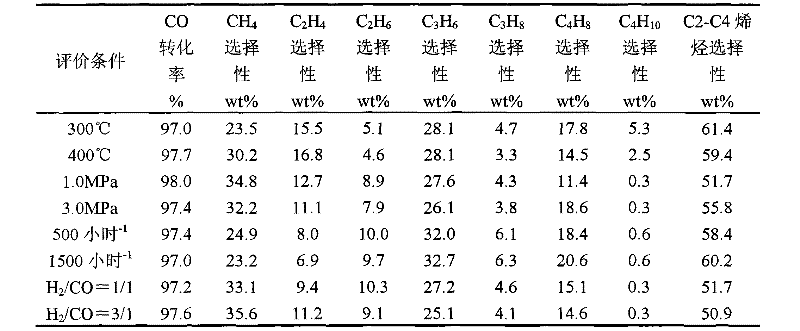

[0027] Table 1 shows the experimental results of the one-step synthesis gas production of light olefins by the prepared catalyst under certain reaction conditions.

Embodiment 2

[0029] The required amount of acid-washed activated alumina carrier is calcined at 900° C. for 2 hours for later use. A certain amount of ferric nitrate, manganese nitrate and potassium nitrate are dissolved in water to form a mixed solution I with a certain concentration. Under vacuum conditions, impregnate the above mixed solution I on the required amount of treated alumina carrier to obtain the catalyst precursor J. The impregnated catalyst precursor J was dried at 110°C, and then calcined at a temperature of 600°C, and the calcining time was 2 hours, to obtain a catalyst for producing low-carbon olefins by one-step synthesis gas, and its composition was as follows:

[0030] 35% Fe 100 mn 50 K 30 o x +65% Al 2 o 3 .

[0031] Table 1 shows the experimental results of the one-step synthesis gas production of light olefins by the prepared catalyst under certain reaction conditions.

Embodiment 3

[0033] The required amount of acid-washed activated alumina carrier is calcined at 1100° C. for 1 hour for later use. A certain amount of ferric nitrate, manganese nitrate and potassium nitrate are dissolved in water to form a mixed solution I with a certain concentration. Under vacuum conditions, impregnate the above mixed solution I on the required amount of treated alumina carrier to obtain the catalyst precursor J. The impregnated catalyst precursor J was dried at 110°C, and then calcined at 400°C for 8 hours to obtain a catalyst for producing low-carbon olefins by one-step synthesis gas.

[0034] 35% Fe 100 mn 50 K 30 o x +65%Al 2 o 3 .

[0035] Table 1 shows the experimental results of the one-step synthesis gas production of light olefins with the prepared catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com