Wax for impregnation and encapsulation of ceramic dielectric capacitors and its preparation method

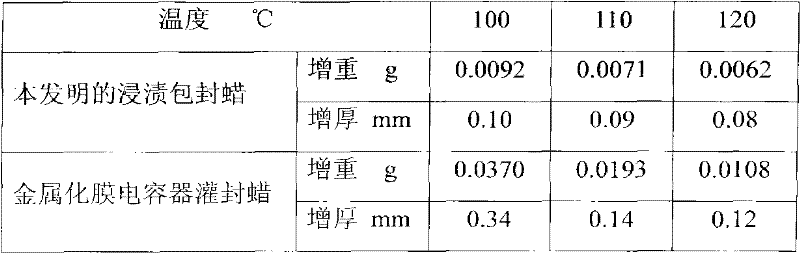

A technology for encapsulating wax and capacitors, which is applied in the direction of fixed capacitor shell/package, fixed capacitor components, etc., can solve the problems of unfavorable improvement of the installation rate and high cost, and achieves suitable physical and chemical properties, good use performance, and dipping coating. thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

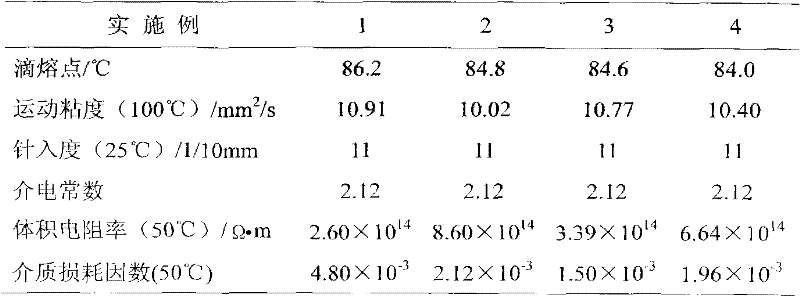

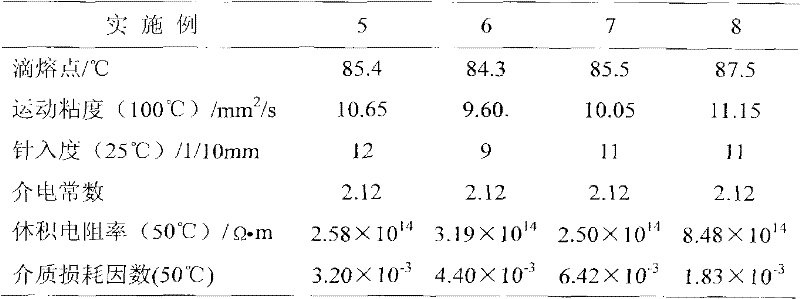

Examples

Embodiment

[0028] Embodiment: (below all represent by weight percentage)

[0029] experiment method

[0030] The following test methods are the usual ones for testing waxes used in the electronics industry used in the examples.

[0031] Dropping melting point GB / T 8026

[0032] Penetration GB / T 4985

[0033] Kinematic viscosity GB / T265

[0034] Dielectric constant GB / T 5654

[0035] Volume resistivity GB / T 5654

[0036] Dielectric loss factor GB / T 5654

Embodiment 1

[0039] No. 80 microcrystalline wax, drop melting point 81.6°C (Jimen Refinery) 62%

[0040] Fully refined paraffin wax No. 62, melting point 62.1°C (Dalian Petrochemical Company) 36%

[0041] Polyethylene wax L-913, average molecular weight 2582 (Beijing Auxiliary No. 2 Factory) 1.8%

[0042] Antioxidant, 2,6-di-tert-butyl-p-cresol (Shenyang Second Reagent Factory) 0.2%

Embodiment 2

[0044] No. 80 microcrystalline wax, drop melting point 81.6°C (Jingmen Oil Refinery) 50%

[0045] No. 64 fully refined paraffin wax, molten gas 65.5°C (Dalian Petrochemical Company) 48%

[0046] Polyethylene wax L-913, average molecular weight 2582 (Beijing Auxiliary No. 2 Factory) 1.5%

[0047] Antioxidant, 2,6-di-tert-butyl-p-cresol (Shenyang Second Reagent Factory) 0.5%

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com