Novel polyethylene powder coating

A polyethylene powder, polyethylene technology, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor metal adhesion, poor compatibility of inorganic fillers, and unsatisfactory mechanical properties of coating films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Composition of raw material parts by weight:

[0011] Linear Low Density Polyethylene 100 parts

[0012] Carbon nanofiber 5 parts

[0013] Epoxy resin (E-10) 10 parts

[0014] 3 parts of silane coupling agent

[0015] Micron inorganic filler 10 parts

[0016] 3 parts of powder additives

[0017] Put 10kg of linear low density polyethylene, 0.3kg of silane coupling agent and 1kg of micron-sized inorganic filler into a high-speed mixer, and after uniform mixing, add 1kg of epoxy resin, 0.5kg of carbon nanofiber mixed powder and 0.3kg of powder additives Mix together well. Put the mixed material into a twin-screw extruder to extrude and granulate, and the temperature of the extruder is 160-180°C. Put the prepared masterbatch granules in a pulverizer and grind them to the required particle size of the powder.

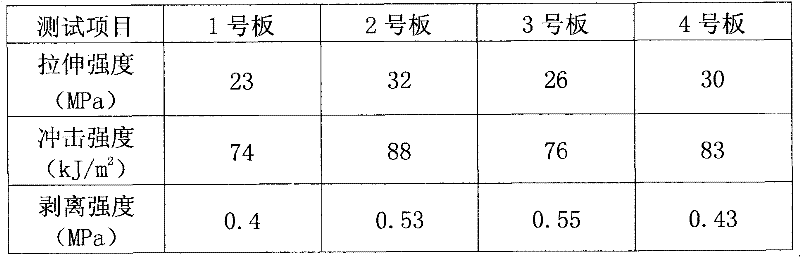

[0018] The obtained powder was sprayed on a standard board (No. 1 board) at 250°C to test its performance.

Embodiment 2

[0020] Composition of raw material parts by weight:

[0021] Linear Low Density Polyethylene 100 parts

[0022] Carbon nanofiber 10 parts

[0023] Epoxy resin (E-10) 15 parts

[0024] 3 parts of silane coupling agent

[0025] Micron inorganic filler 10 parts

[0026] 3 parts of powder additives

[0027] According to the above processing procedures, the plate (No. 2 plate) is tested for performance.

Embodiment 3

[0029] Composition of raw material parts by weight:

[0030] Linear Low Density Polyethylene 100 parts

[0031] Carbon nanofiber 5 parts

[0032] Epoxy resin (E-10) 15 parts

[0033] 3 parts of silane coupling agent

[0034] Micron inorganic filler 10 parts

[0035] 3 parts of powder additives

[0036] Make board (No. 3 board) according to the above processing procedure to test its performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com