Hydrocracking method for reforming material yield increase

A hydrocracking and hydrofining technology, which is applied in the fields of hydrotreating process, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of large equipment investment and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

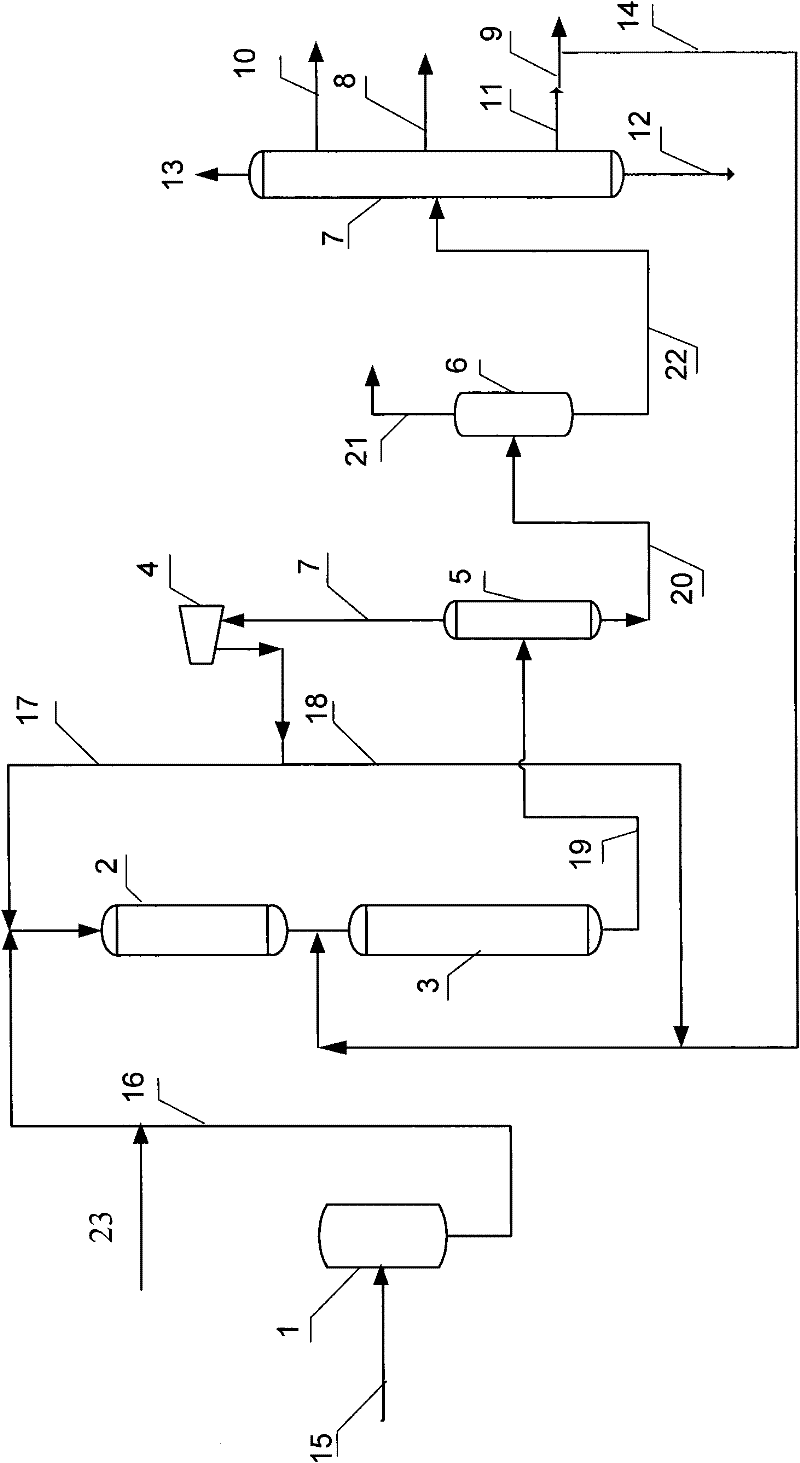

Method used

Image

Examples

Embodiment 1

[0036] When the reaction pressure is 13.0MPa, the reaction temperature of the hydrotreating reactor is 373°C, and the space velocity is 1.2h -1 , hydrocracking reactor reaction temperature 367 ℃, space velocity 2.0h -1 , under the reaction conditions that the volume ratio of hydrogen to oil is 1200. According to the method provided by the present invention, the experiment was carried out with raw material A, in which the 220-320°C light oil fraction accounting for 40% by mass of the total light oil oil was recycled to the inlet of the hydrocracking reactor. The test results are shown in Table 2.

[0037] As can be seen from Table 2, under the condition of> 350 ℃ of conversion rate 61%, the yield of heavy naphtha cut is 31.77% (to fresh raw material), and the yield of kerosene cut is 12.59%; In addition, heavy naphtha The selectivity was 86%.

Embodiment 2

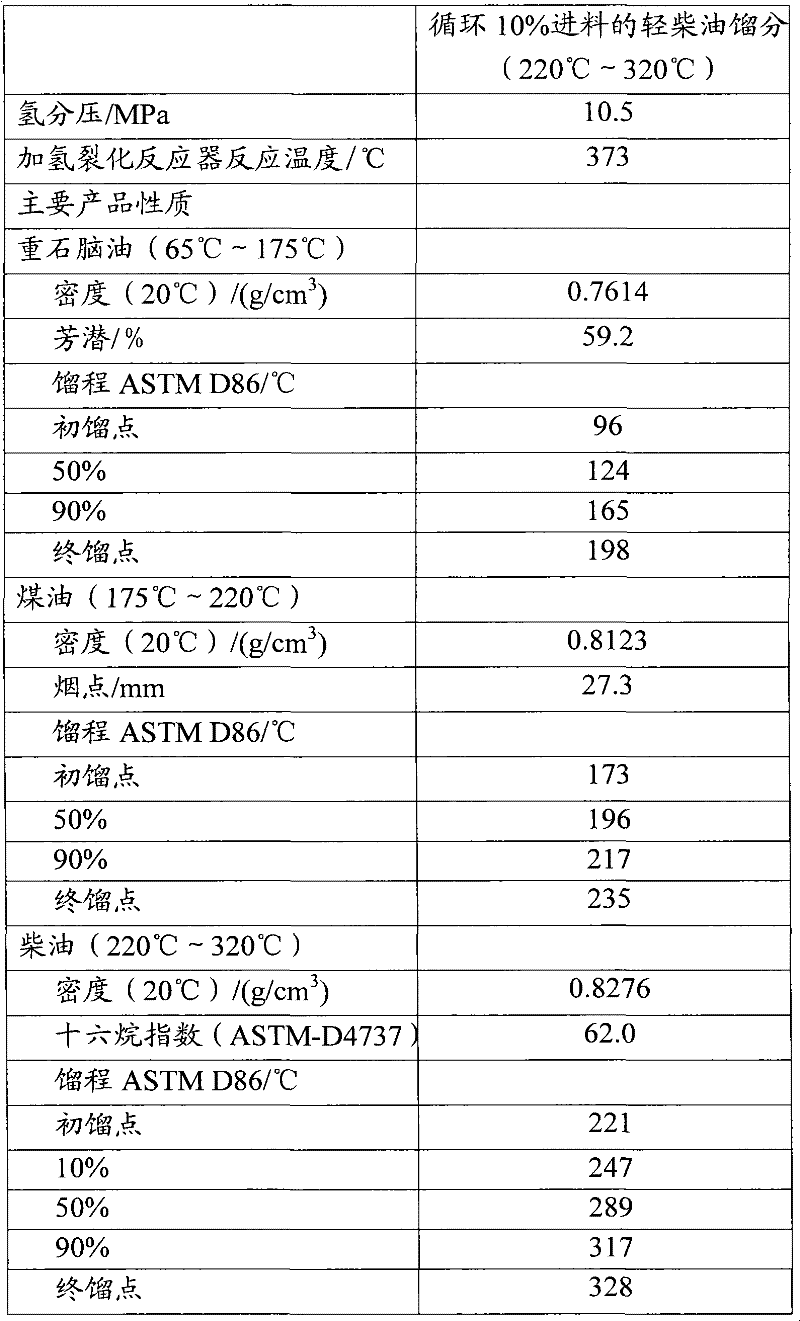

[0042] Adopt the method provided by the present invention, control > 350 ℃ conversion rate is 65%, at reaction pressure 13.0MPa, hydrotreating reactor reaction temperature 375 ℃, space velocity 1.2h -1 , hydrocracking reactor reaction temperature 373 ℃, space velocity 2.0h -1 , under the reaction conditions that the volume ratio of hydrogen to oil is 1200. With the method provided by the present invention, the experiment is carried out with raw material A, wherein the 220-320°C light diesel oil fraction accounting for 10% of the mass fraction of fresh raw material A is recycled to the inlet of the hydrocracking reactor, and the fractions of heavy naphtha, aviation kerosene and diesel oil are Product quality data are listed in Table 4. It can be seen from Table 4 that the aromatic potential of the heavy naphtha obtained from back refining is 59.2, the smoke point of aviation kerosene is 27.3 mm, and the cetane number of light diesel oil is 62.4.

Embodiment 3

[0046] Both improving the conversion rate and refining light diesel oil can increase the yield of heavy naphtha; in order to further understand the difference between the two schemes, at first the yield of heavy naphtha reaches 34% as the target, and the method provided by the invention is used to carry out refining Hydrocracking test of 60% of the total light oil fraction by weight, the reaction pressure is 10.5MPa, the reaction temperature of the hydrotreating reactor is 373°C, and the space velocity is 1.2h -1 , hydrocracking reactor space velocity 2.0h -1 , under the reaction conditions that the volume ratio of hydrogen to oil is 1200. With the method provided by the present invention, the experiment was carried out using raw material A, and the product distribution and hydrogen consumption results are listed in Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com