Carbide composite phase change storage material and preparation method thereof

A technology of composite phase change and storage materials, applied in the field of carbide composite phase change storage materials and preparation, can solve the problems of large current, hinder the market promotion of phase change memory, long time required, etc. Effect of grain size reduction and grain boundary increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

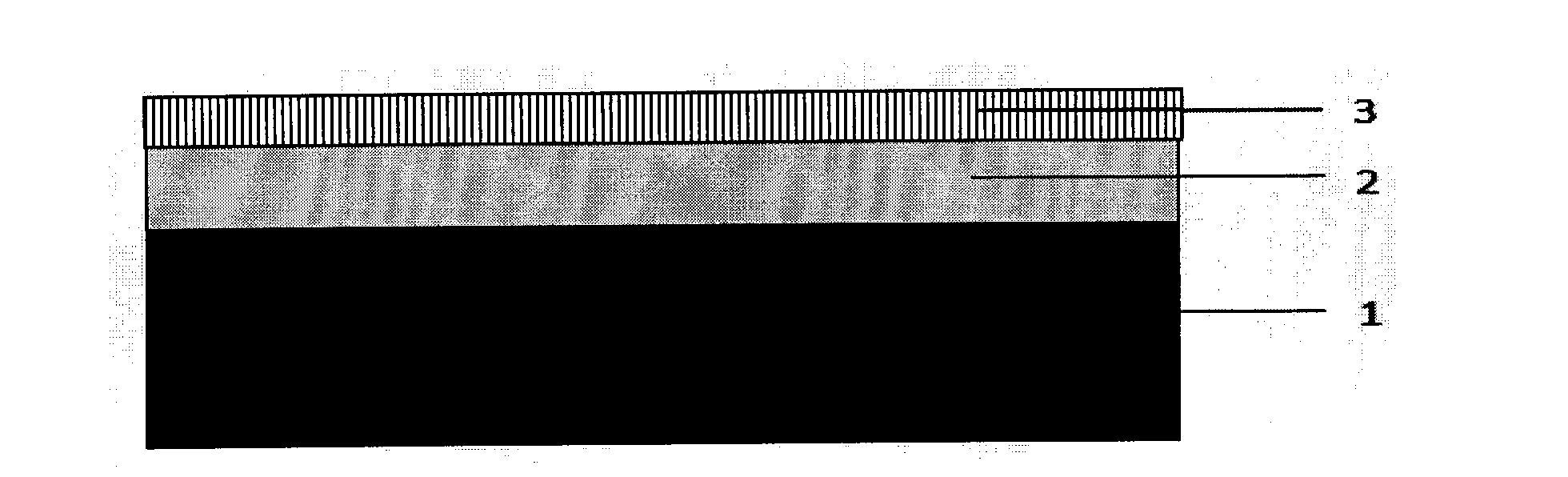

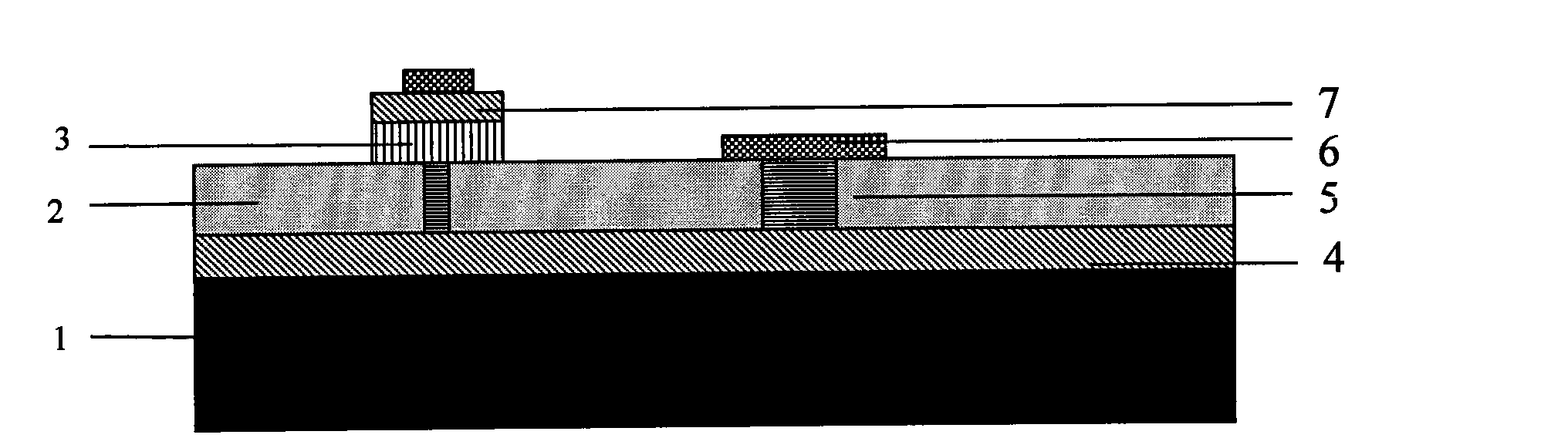

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

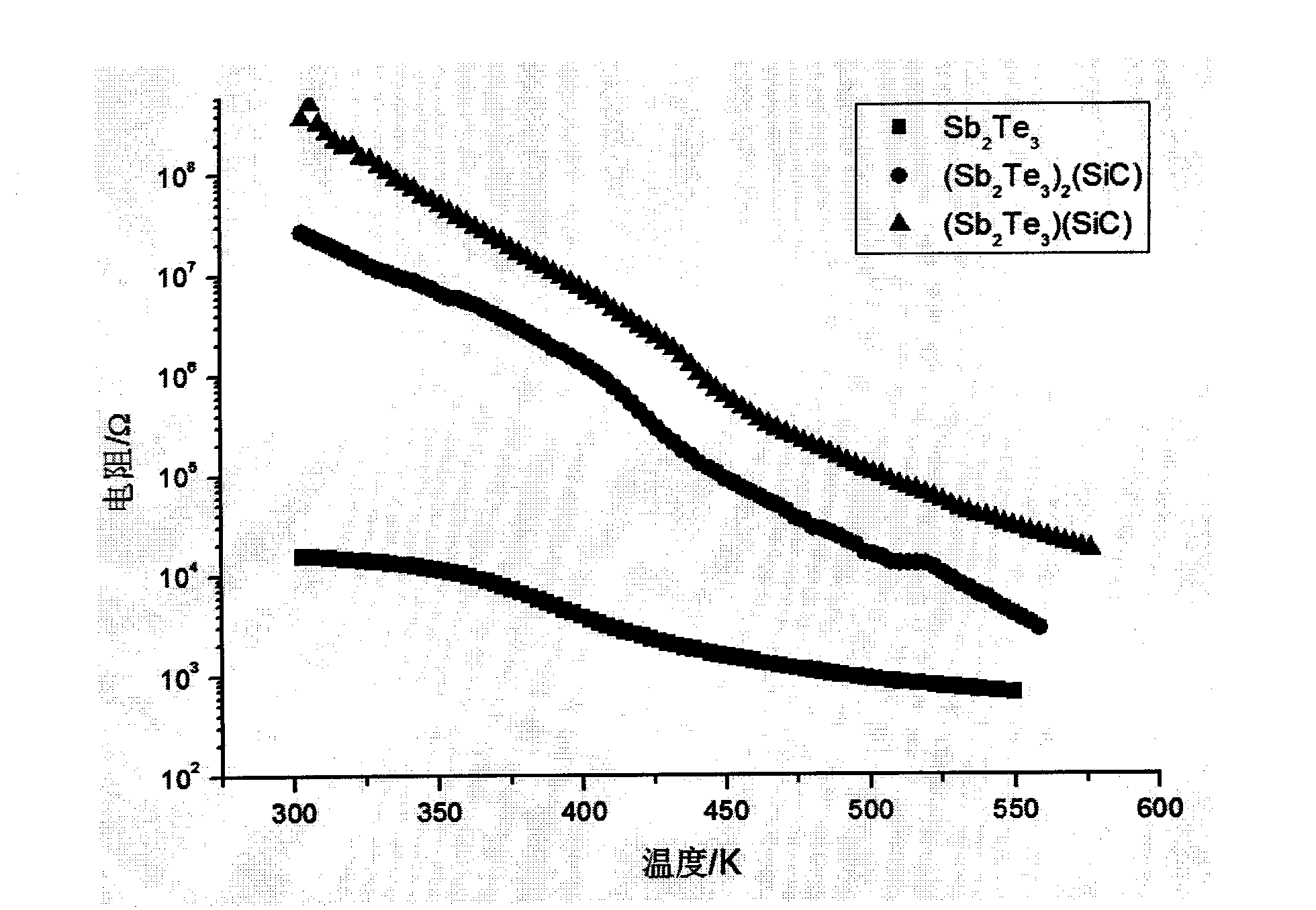

[0021] In this embodiment, silicon carbide (SiC) is used as the doped carbide, and the phase change material is Sb 2 Te 3 As an example, the specific components of the carbide composite phase change storage material are

[0022] (Sb 2 Te 3 ) x (SiC) 100-x , wherein 50≤x≤95, that is, the molar percentage of silicon carbide in the carbide composite phase change material is 5%-50%.

[0023] (Sb 2 Te 3 ) x (SiC) 100-x by Sb 2 Te 3 The target and the SiC target are co-sputtered. The specific experimental conditions are: the sputtering body is argon, and the background vacuum is less than 10 -4 Pa, sputtering pressure is 0.21Pa~0.22pa, sputtering power supply: Sb 2 Te 3 RF power is used, SiC uses RF power, and the deposition thickness is 50-200nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com