Method for crystallizing noncrystalline silicon by induction heating

A technology of induction heating and amorphous silicon, applied in the direction of induction heating, induction heating devices, chemical instruments and methods, etc., can solve the problems of uneven crystallization, high price and maintenance costs, poor stability, etc., and achieve the goal of induction heating equipment Simple, high energy efficiency utilization, high heating efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

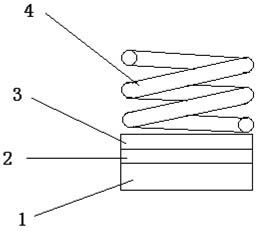

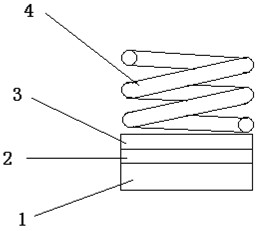

[0009] Such as figure 1 As shown in the schematic diagram of induction heating amorphous silicon crystallization, first deposit a layer of amorphous silicon film 2 on the glass substrate 1, then cover the amorphous silicon film 2 with a layer of metal film 3, and put the opening end of the induction coil 4 close to the metal The induction coil is connected to the induction power supply, and a strong alternating current is passed through the induction coil, which can reach thousands of amperes. A strong alternating magnetic field is generated in the coil, and the alternating magnetic field is perpendicular to the metal film and the amorphous silicon film 2, and the metal film 3 will generate The strong induced eddy current can rapidly heat the metal film 3, thereby heating the amorphous silicon film 2 covered under the metal film 3. After the amorphous silicon is heated, the conductivity is enhanced, and an eddy current is also generated in the alternating magnetic field. Furth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com