Ceramic substrate LED apparatus

A technology of LED devices and ceramic substrates, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of lagging indoor general lighting market, increase heat dissipation surface area, increase PN junction temperature, etc., reduce volume and weight, and improve luminescence Angle, the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement them after reading the description.

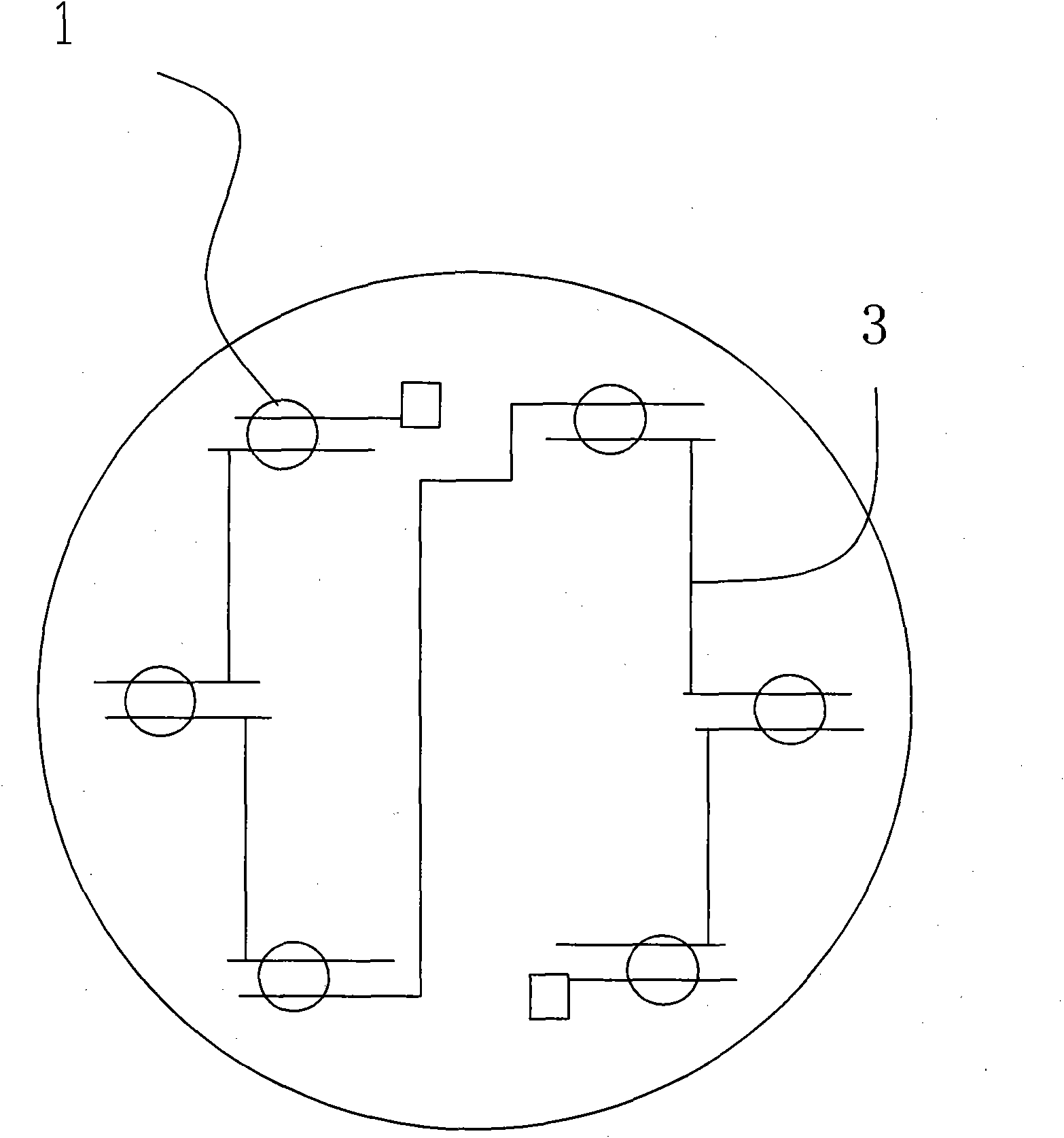

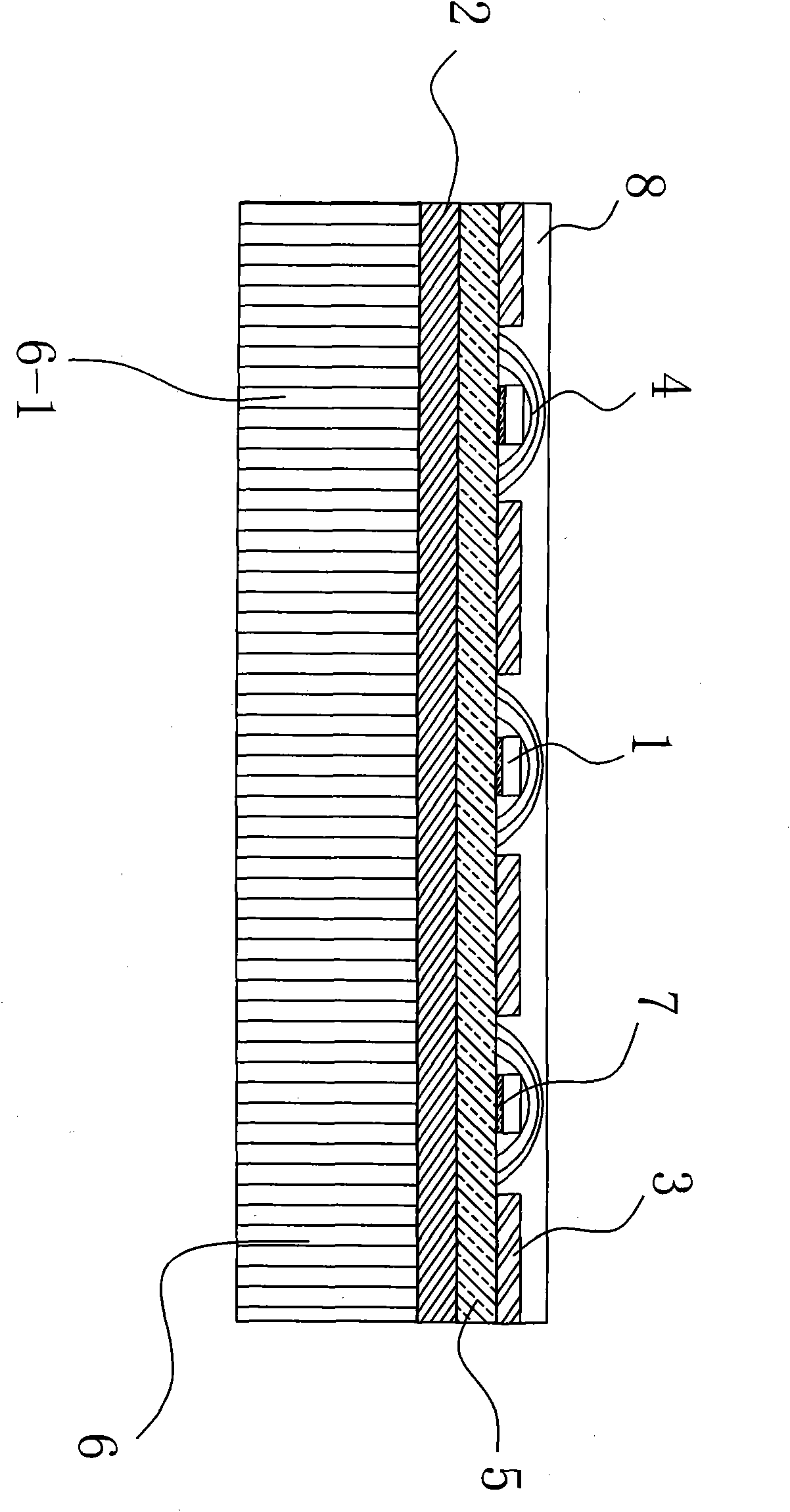

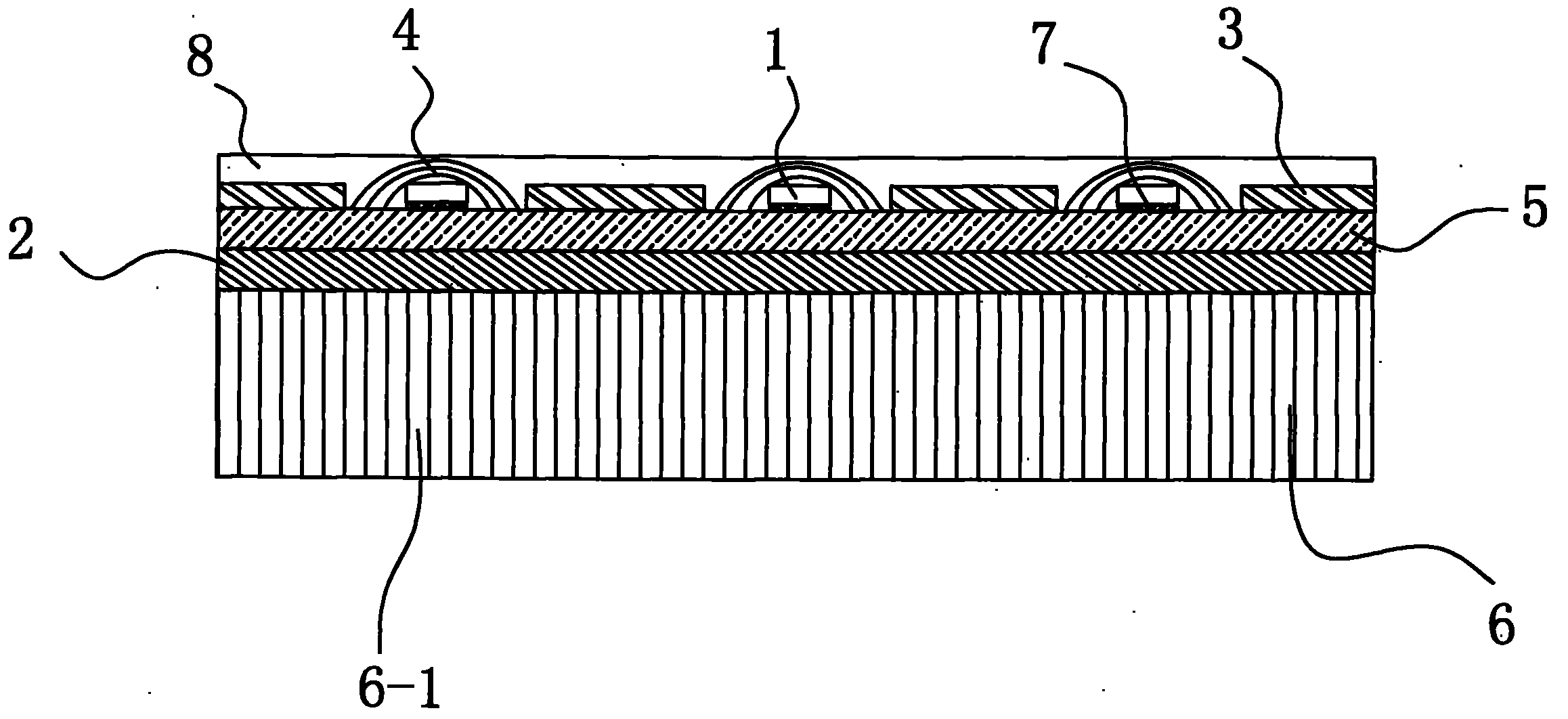

[0025] refer to figure 2 The technical scheme of the present invention includes: LED chip 1, ceramic substrate 6 carrying the chip, circuit layer 3 connected to the LED chip, phosphor powder mixture glue 4 coated on the LED chip, and a bonding layer 7 between the LED chip and the carrying substrate. The ceramic substrate carries the radiation heat dissipation film 2 on one side of the LED and the nano-ceramic glaze coating 5 on the radiation heat dissipation film.

[0026] The phosphor powder mixture glue 4 coated on the LED includes phosphor powder, scattering particles, and silica gel. Phosphor powder mixture 4 is distributed in multiple layers with different concentrations. The density of phosphor powder in the first layer and the second layer adjacent to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com