Surface treatment process and treated article

A main surface, polysilazane technology, applied in the field of surface treatment and treated products, can solve problems such as poor compatibility of manufacturing processes, and achieve the effect of improving the convenience of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

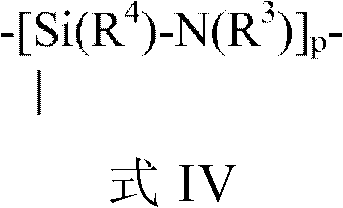

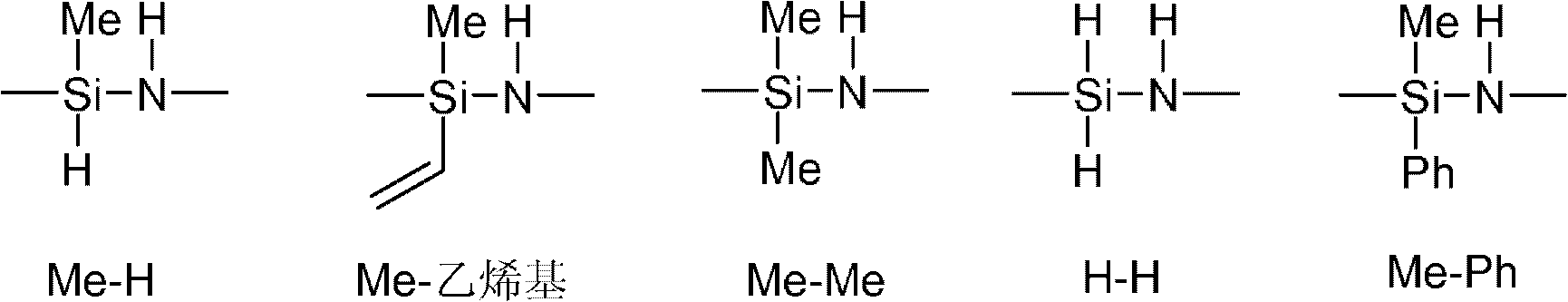

Method used

Image

Examples

Embodiment

[0117] Objects and advantages of this invention are further illustrated by the following examples, but the particular materials and amounts thereof recited in these examples, as well as other conditions and details, should not be construed to unduly limit this invention. These examples are for illustrative purposes only and are not intended to limit the scope of the appended claims.

[0118] Material

[0119] All solvents were of standard reagent grade obtained from commercial sources and were used without further purification unless otherwise noted.

[0120]

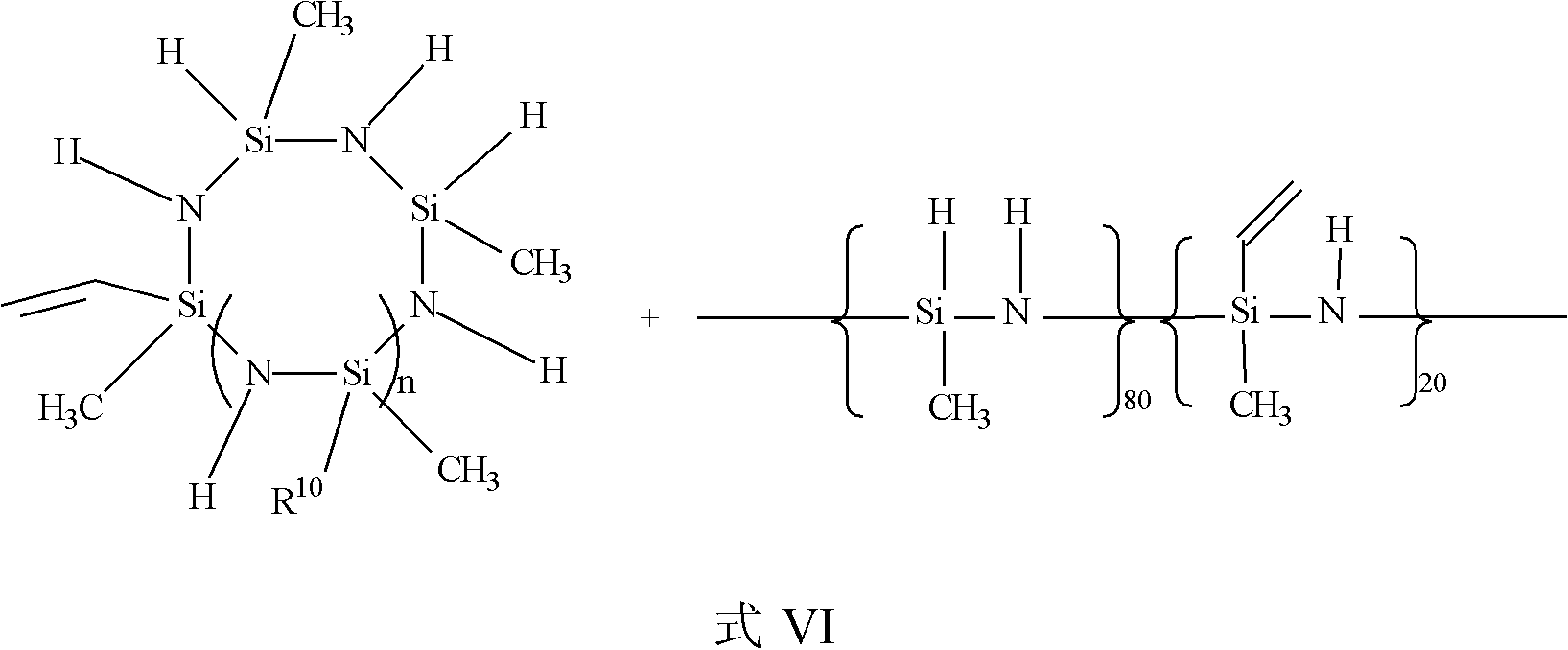

[0121] A 2-liter 3-neck flask equipped with a mechanical stirrer, dry ice (ie, solid carbon dioxide) / acetone condenser, and ammonia inlet tube was charged with hexane (800 mL), methyldichlorosilane (57.7 g, obtained from Alfa Aesar, Ward Hill, MA) and vinylmethyldichlorosilane (17.4 g, available from Alfa Aesar, Ward Hill, MA). Ammonia (obtained from Matheson Tri Gas, Baking Ridge, NJ) was then slowly bubbled int...

example 1

[0153] Will (0.2 g; prepared as described above) and polysilazane PS1 (2 g; prepared as described above) in xylene (2 g) was heated to 130° C. for 4 hours. When the resulting homogeneous solution cooled to room temperature, two layers formed. The solution was diluted with 12 g of ethyl acetate. Then, 0.0136 g of dicumyl peroxide was added to 5 g of this solution, and the resulting solution was applied on an aluminum plate and cured at 150° C. for 18 hours.

example 2

[0155] Example 2 is carried out in substantially the same manner as Example 1, except that Use 0.2g (prepared as above) instead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com