Washing machine

A washing machine and washing water technology, applied in the field of washing machines, can solve the problems of mildew, unpredictable users, washing machine pollution, etc., and achieve the effect of weak adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

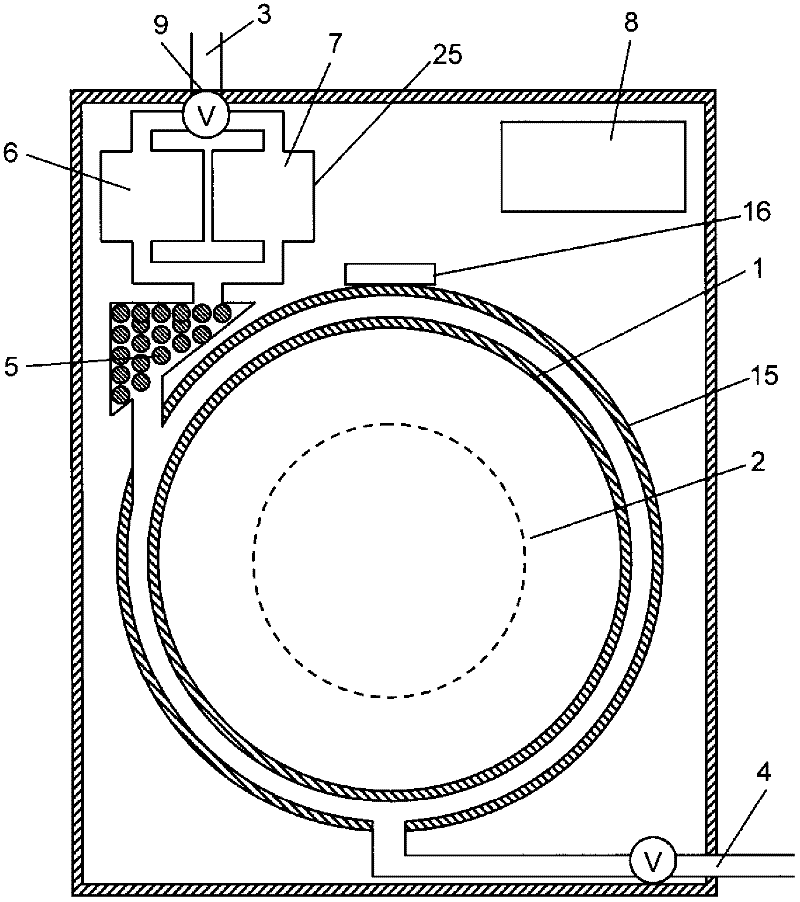

[0028] figure 1 It is a block diagram of the washing machine in Embodiment 1 of this invention. exist figure 1 Among them, the washing machine includes a washing tank 1 , a water tank 15 , a drive unit 16 , a washing unit 2 , a water supply unit 3 , a drain unit 4 , a soft water unit 5 , a detergent box (pH raising unit) 6 , a pH lowering unit 7 and a control unit 8 .

[0029] Here, washing tub 1 accommodates laundry and is rotatable. The cleaning unit 2 is composed of a motor or the like that performs a physical cleaning function by agitating the washing tank 1 . Water supply unit 3 supplies washing water to water tank 15 and washing tank 1 . Drain unit 4 discharges washing water from water tank 15 and washing tank 1 . The soft water part 5 is arranged between the water supply part 3 and the water tank 15, and is filled with a weakly acidic cation exchange material having a weakly acidic cation exchange group with a point of zero charge of pH 7.5 or more and 14 or less. ...

Embodiment approach 2

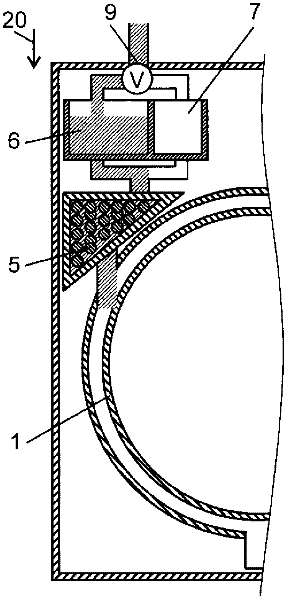

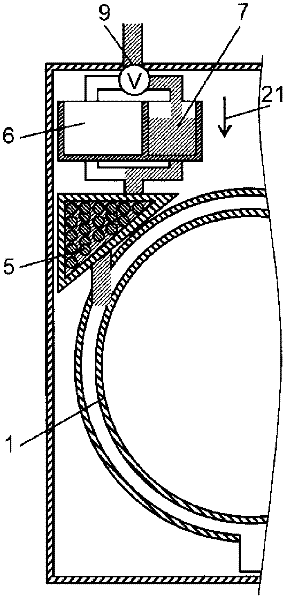

[0049] In Embodiment 2, the same reference numerals are attached to the same components as those in Embodiment 1, and description thereof will be omitted, and only differences will be described. Figure 3A It is a figure which shows the supply situation of the tap water at the time of water supply before the washing|cleaning process of the washing machine concerning Embodiment 2 of this invention. Figure 3B It is a figure which shows the supply situation of the tap water at the time of water supply before the rinsing process of this washing machine.

[0050] In the flow path of Embodiment 2, there is a flow path switching valve 10 between the soft water unit 5 and the washing tub 1, and the flow path can be switched between the direction of the washing tub 1 and the direction of drainage.

[0051] Such as Figure 3A As shown, the process of performing soft water treatment by the soft water unit 5 due to alkaline conditions is the same as that of the first embodiment. At thi...

Embodiment approach 3

[0059] In Embodiment 3, the same reference numerals are attached to the same components as those in Embodiment 1, and description thereof will be omitted, and only differences will be described. Figure 4 It is a configuration diagram of a washing machine according to Embodiment 3 of the present invention.

[0060] The pH lowering unit 7 of the third embodiment is a pair of electrolytic electrodes and a control unit 8 having a voltage application function. An anode 12 serving as a pair of electrolytic electrodes is disposed at a position surrounded by a weakly acidic cation exchange material, and a cathode 13 is disposed adjacent to the anode 12 via a separator 14 .

[0061] When washing water is supplied, no voltage is applied to the pair of electrolysis electrodes. Negative charges appear on the surface of the weakly acidic cation exchange material through the action of alkaline detergent, and play the function of softening water.

[0062] On the other hand, when a DC volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com