Electrostatic spinning method of low molecular weight collagen peptide and chitosan oligosacchaides biological membrane

A technology of chitooligosaccharides and low molecular weight, applied in the field of preparation of composite nanofiber membranes, can solve the problems of insignificant antibacterial effect, poor hydrophilicity of chitosan, slow degradation rate, etc., and achieve adhesion and wound healing The effect of ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

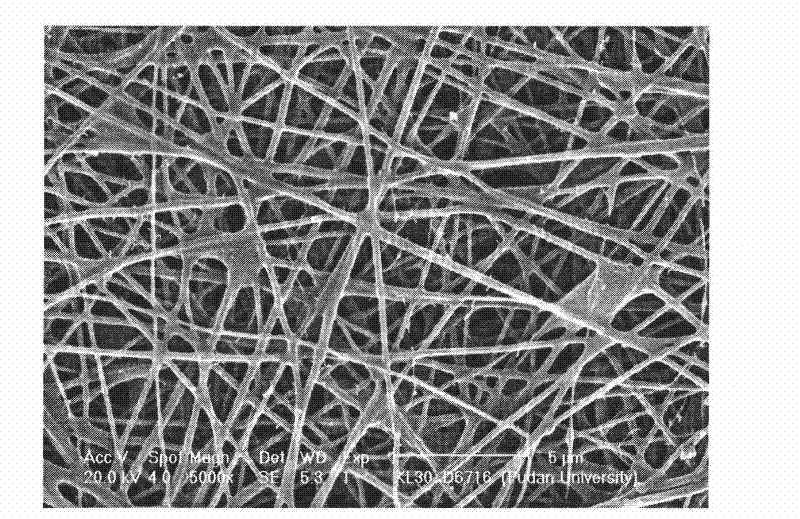

[0041] Preparation of polypeptide / chitooligosaccharide / PVA biofilm

[0042] One of the spinning solutions was prepared: 0.2 g of low-molecular-weight collagen peptide was dissolved in 6 ml of double-distilled water, and placed at room temperature until completely dissolved.

[0043] The second configuration of the spinning solution: 0.3 g of chitooligosaccharides was dissolved in 5 ml of formic acid solvent, and placed at 4° C. until completely dissolved.

[0044] The third preparation of the spinning solution: dissolve 0.6 g of PVA in 10 ml of double distilled water, shake and mix well, and let stand at room temperature until completely dissolved.

[0045] The above three spinning solutions were mixed, put into a magnetic stirring rotor, stirred and mixed for about 3 hours, and refrigerated at 4°C for later use. The mixed spinning solution needs to be stirred in a mixer for about 1 hour to make it evenly mixed before use, and ultrasonically degassed for 15 minutes before usi...

Embodiment 2

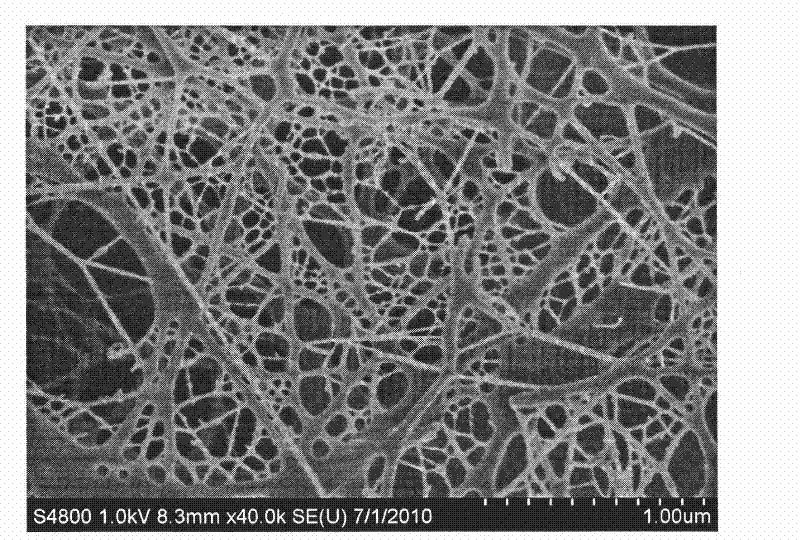

[0049] A biofilm electrospinning method of low molecular weight collagen peptides and chitooligosaccharides, the method comprising the following steps:

[0050] (1) Preparation of spinning solution:

[0051] dissolving chitooligosaccharides with deacetylation degree>90% and viscosity<100cps in formic acid to prepare a chitooligosaccharide formic acid solution with a mass concentration of 3%;

[0052] Dissolving low-molecular-weight collagen peptides in double-distilled water to prepare an aqueous solution of collagen peptides with a mass concentration of 8%;

[0053] Dissolving polyvinyl alcohol in double distilled water to prepare an aqueous polyvinyl alcohol solution with a mass concentration of 5%;

[0054] (2) Chitooligosaccharide formic acid solution and collagen peptide aqueous solution are mixed in a weight ratio of 1: 3, then add polyvinyl alcohol aqueous solution in the mixture obtained, and the weight ratio of the mixed solution and polyvinyl alcohol aqueous solutio...

Embodiment 3

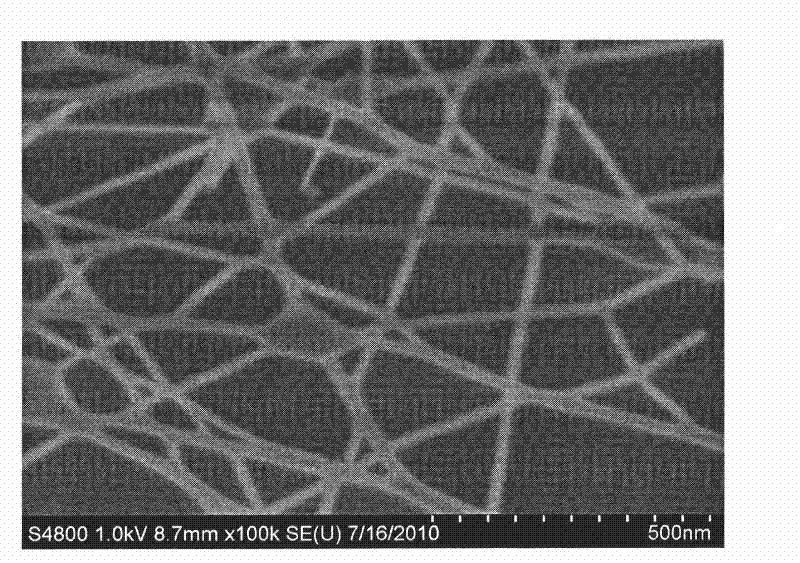

[0056] A biofilm electrospinning method of low molecular weight collagen peptides and chitooligosaccharides, the method comprising the following steps:

[0057] (1) Preparation of spinning solution:

[0058] dissolving chitooligosaccharides with deacetylation degree>90% and viscosity<100cps in formic acid to prepare a chitooligosaccharide formic acid solution with a mass concentration of 5%;

[0059] Dissolving low-molecular-weight collagen peptides in double-distilled water to prepare an aqueous solution of collagen peptides with a mass concentration of 16%;

[0060] Dissolving polyvinyl alcohol in double distilled water to prepare an aqueous polyvinyl alcohol solution with a mass concentration of 8%;

[0061] (2) the chitooligosaccharide formic acid solution and the collagen peptide aqueous solution are mixed in a weight ratio of 1: 2, and then an aqueous polyvinyl alcohol solution is added in the resulting mixture, and the weight ratio of the mixed solution and the aqueous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com