Preparation method for high purity reactive black used for digital ink-jet printing

A digital inkjet and reactive black technology, applied in the direction of organic dyes, etc., to achieve the effect of accelerating development, facilitating industrial production and popularization and application, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Raw material analysis

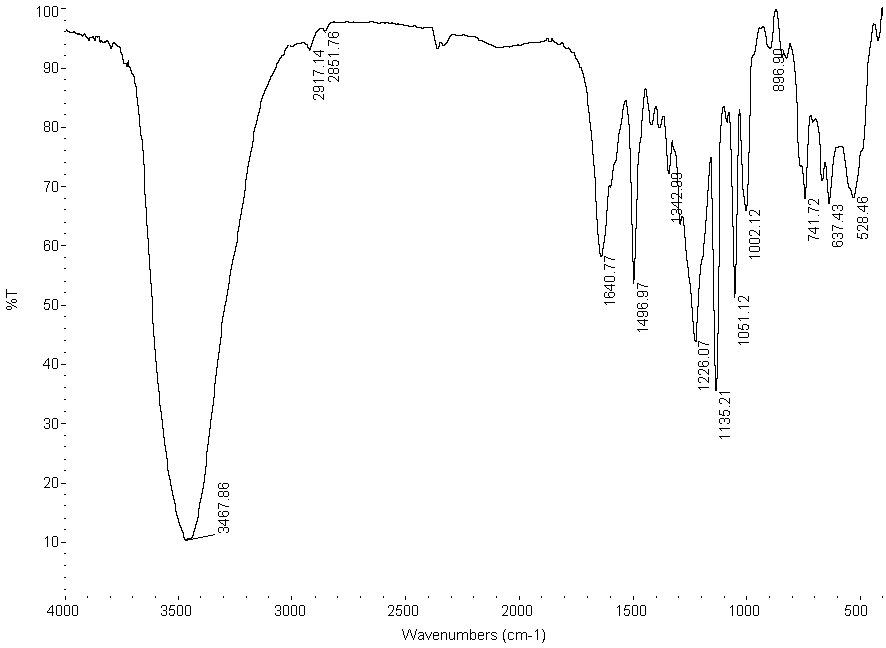

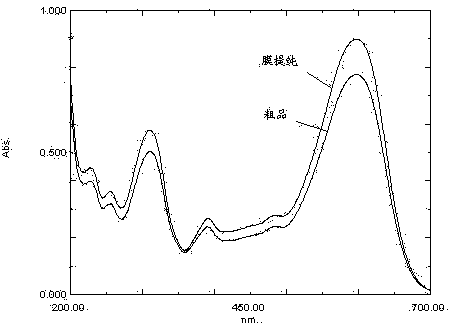

[0040] The raw materials used in this experiment were provided by a domestic dyestuff manufacturer. After analysis, the dye content in the raw material was 84.5% (mass percentage, the same below), the NaCl content was 11.3%, and the NaSO 4 The content is 1.4%, and the organic impurity content is 2.8%. The infrared spectrum of the dye is shown in figure 2 .

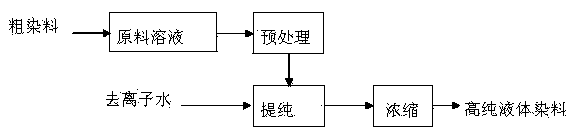

[0041] (2) Separation process

[0042] First prepare a dye aqueous solution containing 6% (mass percentage) of raw materials, and remove particulate impurities through a 0.45um microfiltration membrane. Microfiltration membrane area is 1m 2 , 240 kg of feed solution was obtained in 2.5 hours under the condition of 0.2 MPa.

[0043] Take 240kg of the pretreated dye aqueous solution, and use a charged mosaic membrane to carry out constant-volume membrane filtration. The operating conditions selected for the experiment are pressure of 0.8 Pa; fluid flow of 80-120 L / min. The membrane ...

Embodiment 2

[0053] Research on main influencing factors in the purification process of reactive black in embodiment 2

[0054] The effects of operating pressure, feed liquid flow rate and feed liquid initial concentration on the purification process of reactive black were investigated experimentally.

[0055] ①Influence of operating pressure

[0056] As the operating pressure increases, the permeate flux of the membrane increases almost linearly with the pressure. Although the content of inorganic salts in the permeate decreases, the total amount of inorganic salts in the permeate increases per unit time. The results show that the increase of operating pressure is beneficial to the permeation of inorganic salts, which can reduce the operating time; on the other hand, the dye content in the permeate liquid also increases with the increase of pressure, indicating that the dye loss rate increases accordingly. The experimental conclusion shows that there is a more economical operating pr...

Embodiment 3

[0060] The raw materials used in Example 3 are imported low-salt dyes provided by a certain company. After analysis, the dye content in the raw materials is 87.7% (mass percentage, the same below), the NaCl content is 3.9%, and the NaSO 4 The content is 6.7%, and the organic impurity content is 1.7%.

[0061] Adopt the same method of embodiment 1 to separate, the main parameters of the separation process and most of the product quality indicators are basically close to embodiment 1, but SO 4 2- Content is 307.07ppm; Slightly higher than embodiment 1, but lower than SO 4 2- content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com