Ferroferric oxide nano crystal loaded on acid-modified carbon nano tube and preparation method thereof

A technology of ferric tetroxide and carbon nanotubes, applied in chemical instruments and methods, alkali metal oxide/hydroxide, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reduced use effect and falling off , energy consumption and other issues, to achieve the effect of simple load method, tight integration and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

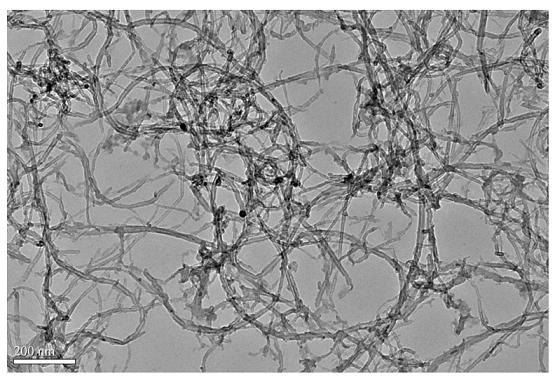

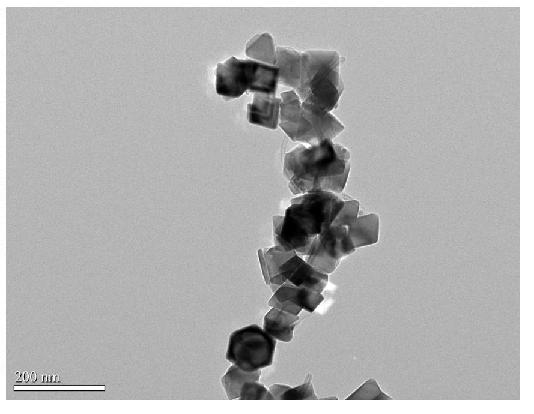

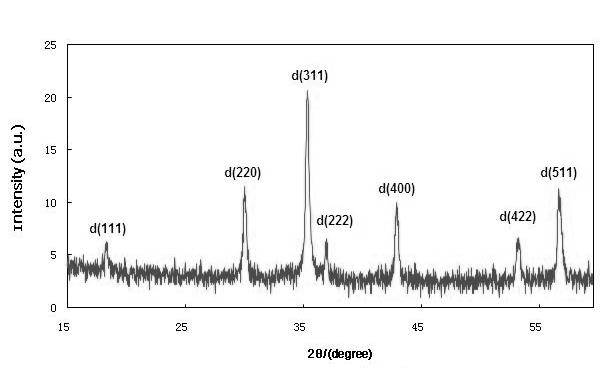

[0033] Weigh 5 mg of multi-walled carbon nanotubes, add 3 ml of concentrated nitric acid and 9 ml of concentrated sulfuric acid, ultrasonicate at 50°C for 2 hours, cool, dilute with deionized water, filter, and wash. The modified carbon nanotubes were dispersed in 80 ml of water, 4 g of ferrous sulfate heptahydrate was added, placed in a water bath at 90° C., and nitrogen was blown to drive away oxygen. Preparation contains 40 milliliters of the mixed solution of 0.093 gram per milliliter of sodium hydroxide and 0.045 gram of per milliliter of sodium nitrate, and under keeping nitrogen flowing and stirring, this mixed solution is added dropwise in the above-mentioned mixed solution containing ferrous sulfate and carbon nanotubes, After the dropwise addition was completed, the temperature was continued for 2 hours. The generated black magnetic solid is separated from the liquid, and then ultrasonically washed 8 times and dried to obtain the carbon nanotube-supported ferric oxid...

Embodiment 2

[0035] Weigh 5 mg of multi-walled carbon nanotubes, add 3 ml of concentrated nitric acid, 9 ml of concentrated sulfuric acid, ultrasonicate at 60°C for 1 hour, cool, dilute with deionized water, filter, and wash. The modified carbon nanotubes were dispersed in 50 ml of water, 2 g of ferrous sulfate heptahydrate was added, placed in a water bath at 90° C., and nitrogen was blown to drive away oxygen. Preparation contains 40 milliliters of the mixed solution of 0.047 gram per milliliter of sodium hydroxide and 0.023 gram of per milliliter of sodium nitrate, and under keeping stirring with nitrogen, this mixed solution is added dropwise in the above-mentioned mixed solution containing ferrous sulfate and carbon nanotubes, After the dropwise addition was completed, the insulation was continued for 3 hours. The generated black magnetic solid is separated from the liquid, and then ultrasonically washed 8 times and dried to obtain the carbon nanotube-supported ferric oxide nanocrysta...

Embodiment 3

[0037] Weigh 10 mg of multi-walled carbon nanotubes, add 10 ml of concentrated nitric acid, 20 ml of concentrated sulfuric acid, ultrasonicate at 70°C for 1 hour, cool, dilute with deionized water, filter, and wash. The modified carbon nanotubes were dispersed in 100 ml of water, 4 g of ferrous sulfate heptahydrate was added, placed in a water bath at 90° C., and nitrogen was blown to drive away oxygen. Preparation contains 20 milliliters of the mixed solution of 0.20 gram per milliliter of potassium hydroxide and 0.045 gram of per milliliter of sodium nitrate, and under keeping nitrogen flowing and stirring, this mixed solution is added dropwise in the above-mentioned mixed solution containing ferrous sulfate and carbon nanotubes, After the dropwise addition was completed, the insulation was continued for 3 hours. The generated black magnetic solid is separated from the liquid, and then ultrasonically washed 8 times and dried to obtain the carbon nanotube-supported ferric oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com