in-situ reinforced active liquid-phase diffusion welding method of aluminium base composite and three-element active solder of al-cu-ti system

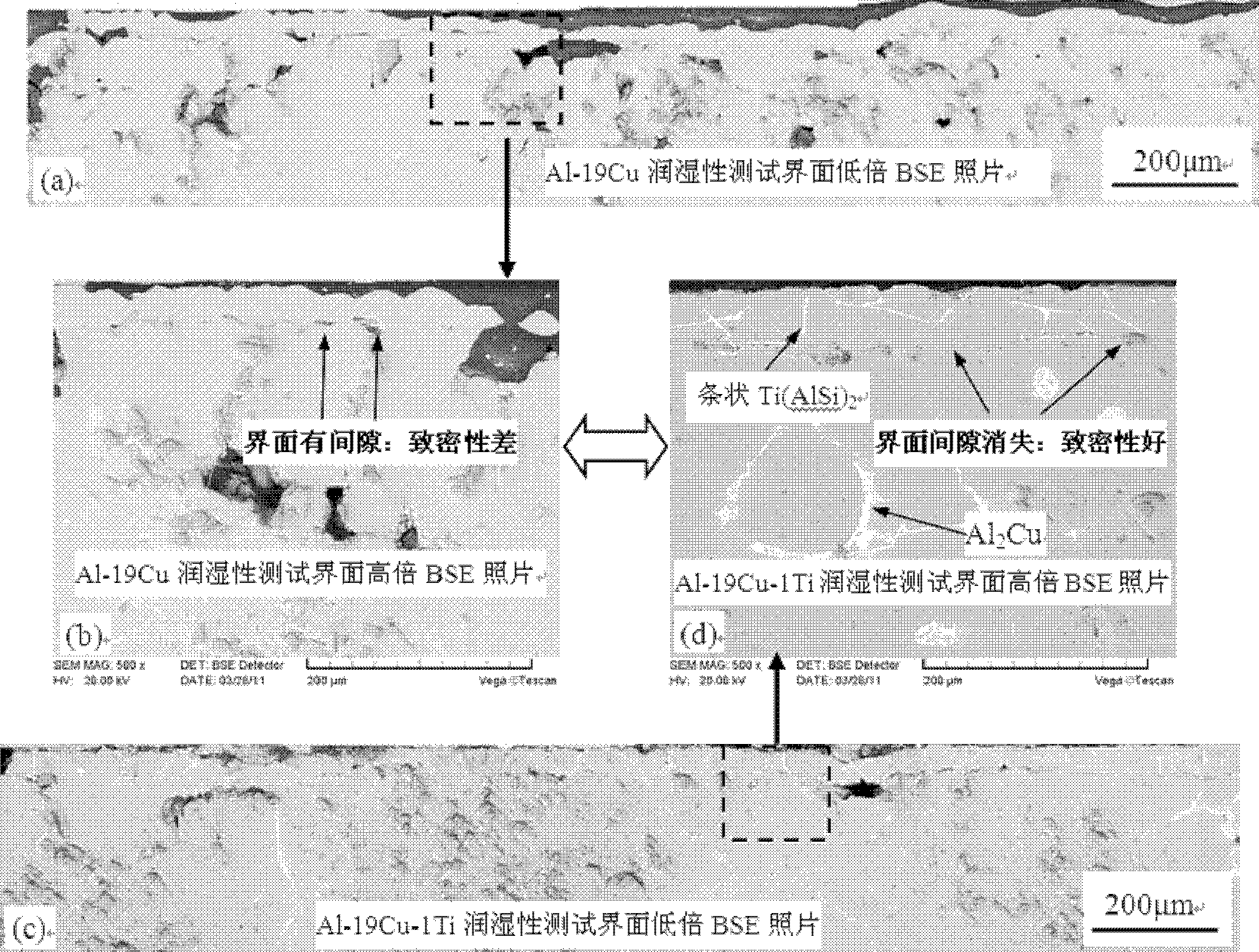

An aluminum-based composite material, in-situ strengthening technology, applied in welding/cutting media/materials, welding equipment, metal processing equipment, etc. Achieve the effect of eliminating interfacial voids, eliminating segregation of ceramic particles and densifying the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

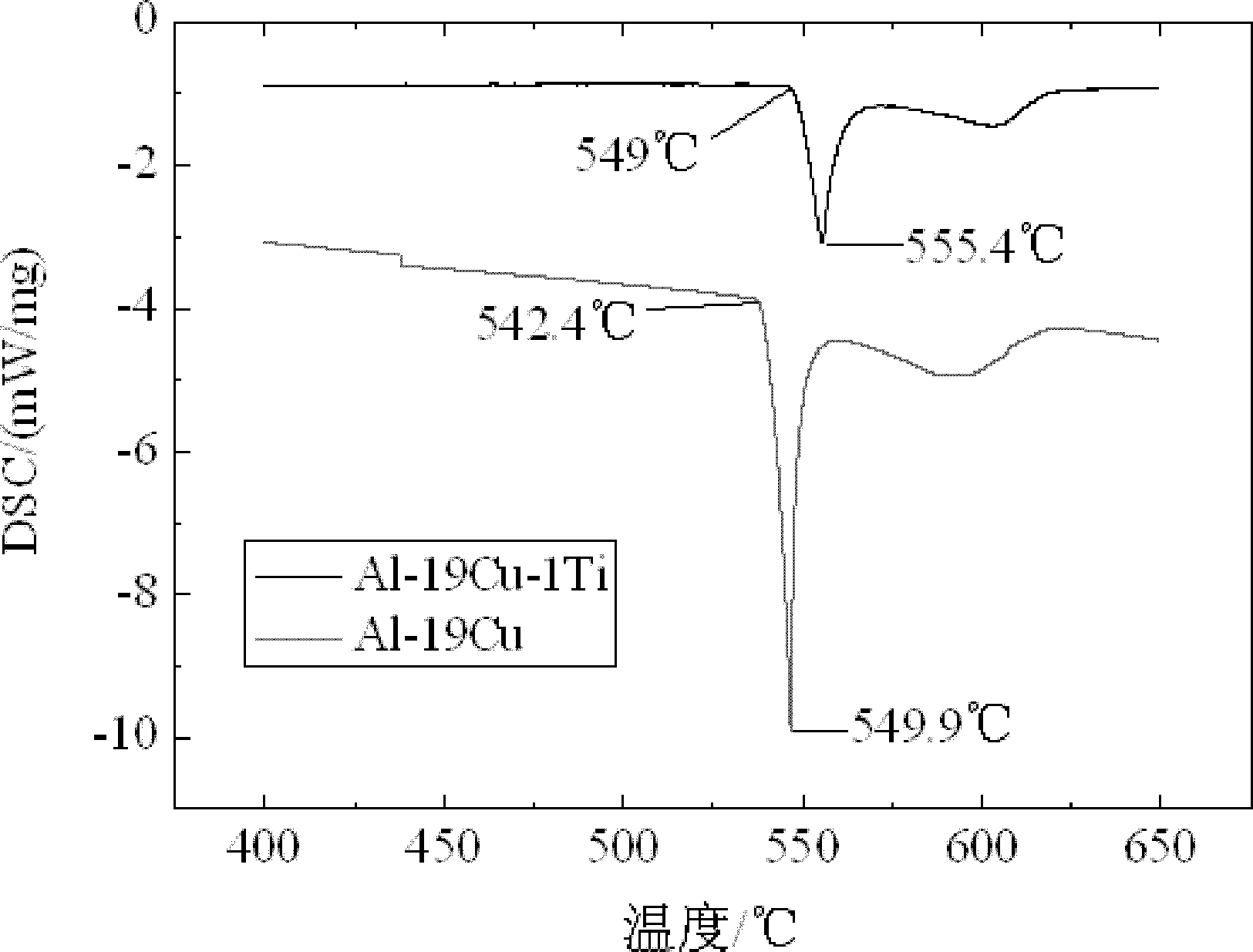

[0070] Embodiment 1: Melting and preparation of Al-19Cu-1Ti

[0071] In this embodiment, the preparation method of Al-Cu-Ti ternary active solder for in-situ strengthened aluminum matrix composite materials can be realized, and the steps are as follows:

[0072] 1) Material selection

[0073] The selected raw materials are: block pure Al, rod-shaped copper T2 and block Al-5Ti master alloy;

[0074] 2) Ingredients

[0075] Mix block Al-5Ti master alloy (6.84g), rod-shaped copper T2 (6.5g) and block-shaped pure aluminum ingot (20.8g) so that the mass percentage of Cu in the mixture is 19% to prevent ternary active solder The melting point is too high or brittle, the mass percentage of Ti is 1%, and the balance is Al; and the mixture is placed in the crucible;

[0076] 3) Smelting

[0077] First pass high-purity Ar (99.99%) into the crucible, and discharge the air in it; then, under the protection of Ar gas, use high-frequency induction heating to heat up to the melting tempe...

Embodiment 2

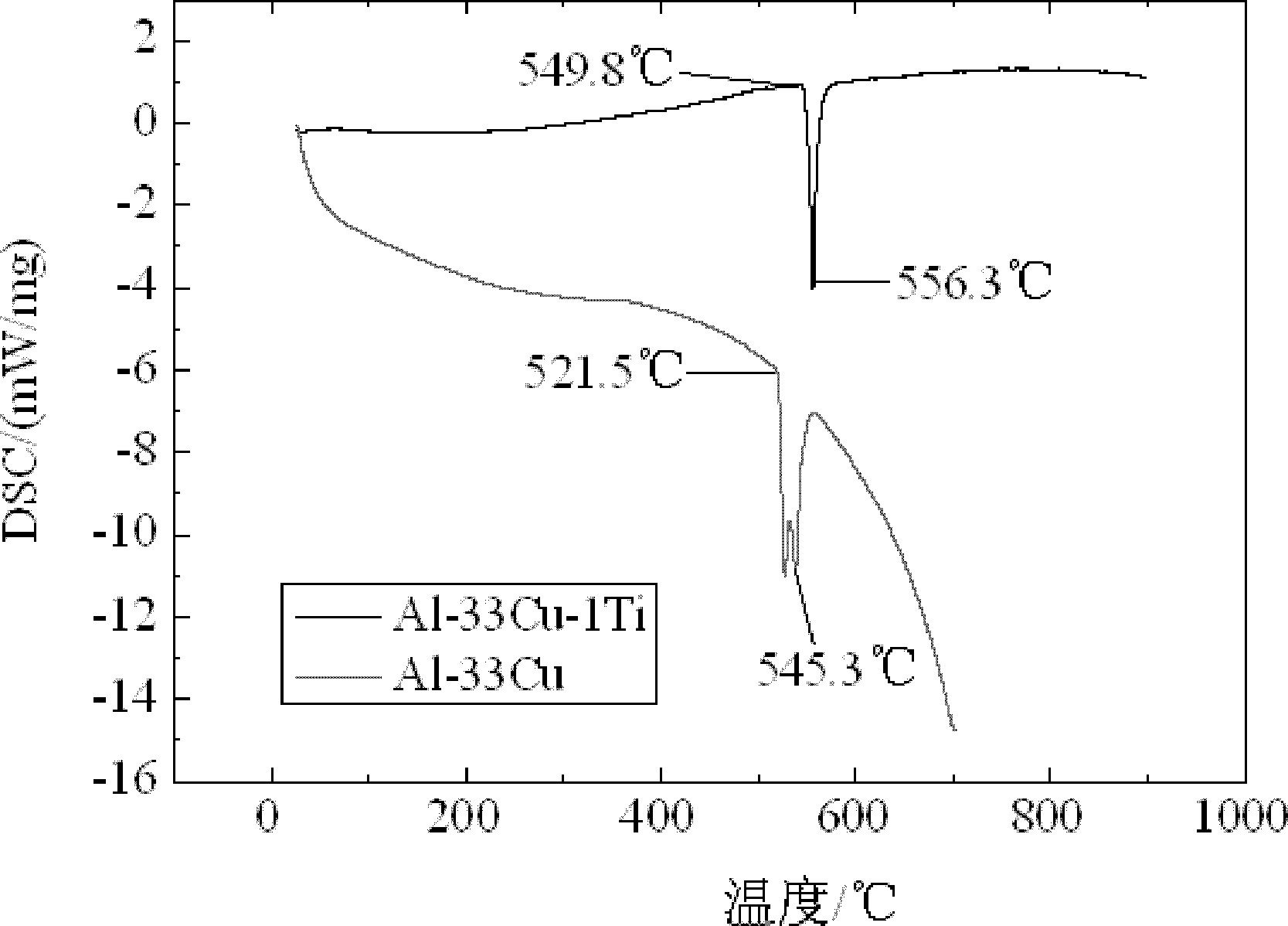

[0080] Embodiment 2: Melting and preparation of Al-33Cu-1Ti

[0081] In this embodiment, the preparation method of Al-Cu-Ti ternary active solder for in-situ strengthened aluminum matrix composite materials can be realized, and the steps are as follows:

[0082] 1) Material selection

[0083] The selected raw materials are: block pure Al, rod-shaped copper T2 and block Al-5Ti master alloy;

[0084] 2) Ingredients

[0085] Mix block Al-5Ti master alloy (3.75g), rod-shaped copper T2 (6.24g) and block-shaped pure aluminum ingot (8.9g) so that the mass percentage of Cu in the mixture is 33% to prevent ternary active solder The melting point is too high or brittle, the mass percentage of Ti is 1%, and the balance is Al; and the mixture is placed in the crucible;

[0086] 3) Smelting

[0087] First pass high-purity Ar (99.99%) into the crucible, and discharge the air in it; then, under the protection of Ar gas, use high-frequency induction heating to heat up to the melting tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com