Method for preparing anhydrous magnesium chloride by utilizing magnesium chloride hexahydrate

A technology of magnesium chloride hexahydrate and anhydrous magnesium chloride, which is applied in the direction of magnesium chloride and magnesium halide, can solve the problems of low utilization rate of chlorine gas, easy blockage of pipelines, and large investment in tail gas treatment, so as to reduce environmental protection input costs, reduce production costs, shorten The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 17.7g of magnesium chloride hexahydrate and 2.4g of ammonium chloride were ball milled with a ball with a diameter of 10mm, the mass ratio of the ball to the solid material was 1:6, and after ball milling for 60 minutes, a mixture of ammonium carnallite and magnesium chloride hexahydrate was obtained. The mixture was kept at 160° C. for 3 hours to obtain a mixture of ammonium carnallite and magnesium chloride hexahydrate. The mixture was put into a 50ml crucible, and then 12g of quartz sand was covered on the carnallite material. Put the lid on the crucible and first keep it warm at 410°C for 1.5 hours, and then keep it warm at 700°C for 0.5 hour, so that the upper layer of quartz sand and the lower layer of anhydrous magnesium chloride with obvious stratification are obtained. In this embodiment, based on the addition of 1.00 parts by weight of magnesium chloride hexahydrate, the addition of quartz sand is 0.68 parts by weight, and the addition of ammonium chloride is 0...

Embodiment 2

[0044] 17.7g of magnesium chloride hexahydrate and 4.7g of ammonium chloride were ball milled with a ball with a diameter of 10mm, the mass ratio of the ball to the solid material was 1:6, and ammonium carnallite was obtained after ball milling for 60 minutes. Ammonium carnallite was kept at 160°C for 3 hours to obtain low-water ammonium carnallite (MgCl 2 ·NH 4 Cl nH 2 O, n=0.8), put the low-water ammonium carnallite into a 50ml crucible, then cover the low-water ammonium carnallite material with 12g of alumina, put the lid on the crucible and keep it warm at 250°C 1.5 hours, and then kept at 700°C for 0.5 hours, so that the upper layer of alumina and the lower layer of anhydrous magnesium chloride with obvious stratification were obtained. In this embodiment, based on the addition of 1.00 parts by weight of magnesium chloride hexahydrate, the addition of aluminum oxide is 0.68 parts by weight, and the addition of ammonium chloride is 0.27 parts by weight.

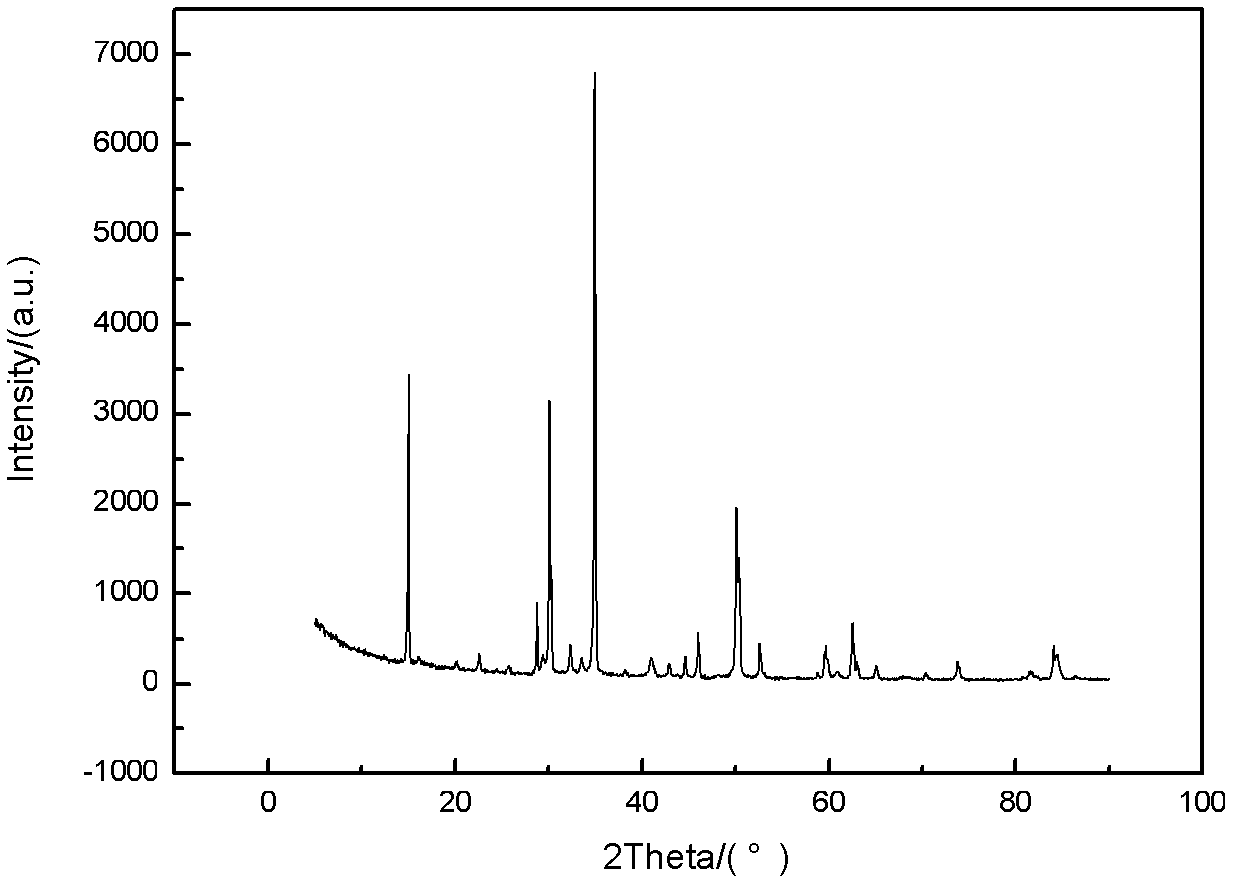

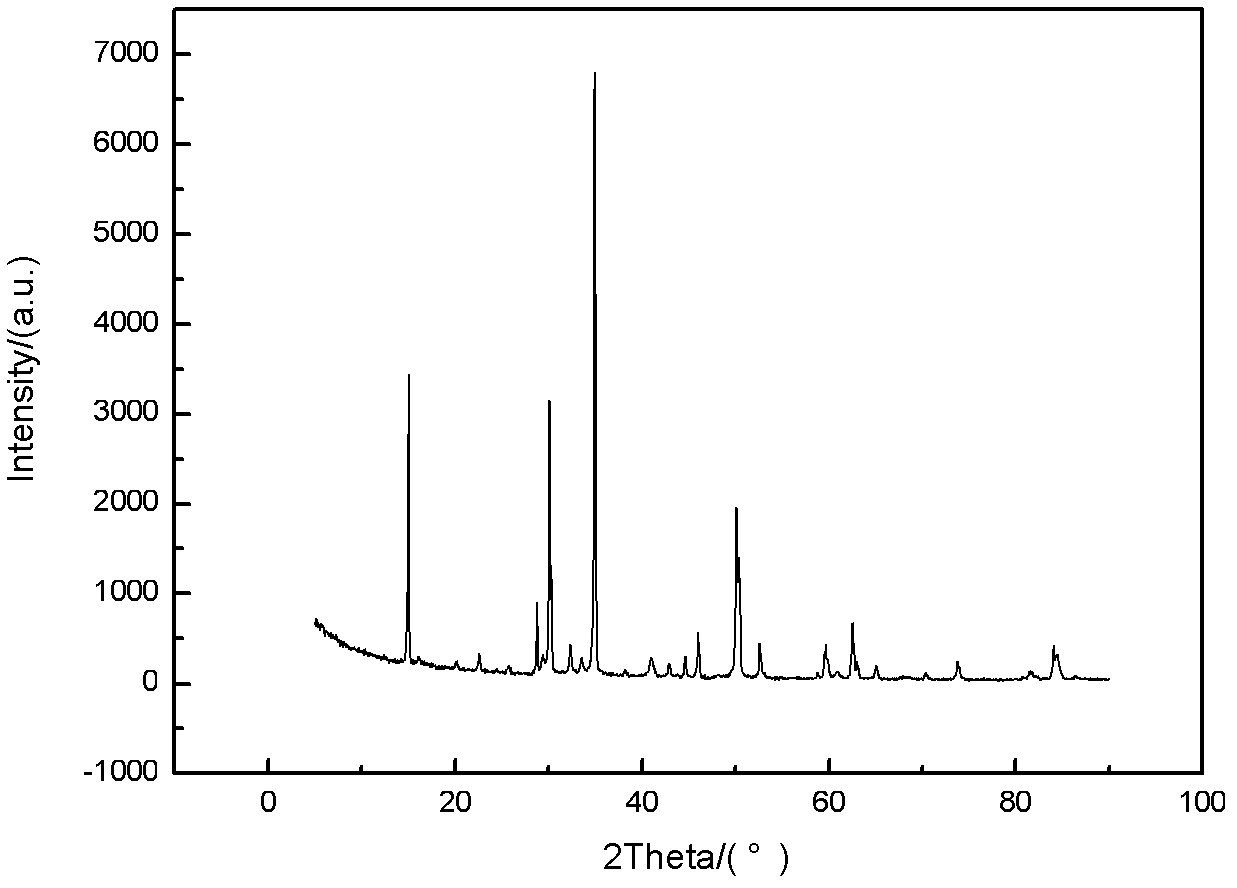

[0045] The obt...

Embodiment 3

[0050] 17.7g of magnesium chloride hexahydrate and 4.7g of ammonium chloride were ball milled with a ball with a diameter of 10mm, the mass ratio of the ball to the solid material was 1:6, and ammonium carnallite was obtained after ball milling for 60 minutes. Ammonium carnallite was kept at 160°C for 3 hours to obtain low-water ammonium carnallite (MgCl 2 ·NH 4 Cl nH 2 O, n=0.7), put the low-water ammonium carnallite into a 50ml crucible, then cover 12g of alumina on the low-water ammonium carnallite material, put the lid on the crucible and keep it warm at 300°C 1.5 hours, and then kept at 700°C for 0.5 hours, so that the upper layer of alumina and the lower layer of anhydrous magnesium chloride with obvious stratification were obtained. In this embodiment, based on the addition of 1.00 parts by weight of magnesium chloride hexahydrate, the addition of aluminum oxide is 0.68 parts by weight, and the addition of ammonium chloride is 0.27 parts by weight.

[0051] The obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com