Preparation method of dumbbell-shaped bismuth vanadate

A technology of bismuth vanadate and dumbbells is applied in the field of preparation of new photocatalysts, which can solve the problems of undiscovered preparation methods of dumbbell-shaped bismuth vanadate, and achieve controllable morphology and crystal phase, mild conditions and good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0040] This example prepares dumbbell-shaped BiVO 4 The method has the following steps:

[0041] ①Weigh 20.0205g (0.001mol) of polyethylene glycol 20000 (hereinafter referred to as PEG-20000, CAS No. 25322-68-3) white solid powder into a beaker filled with 200 mL of water, stir magnetically until PEG-20000 20,000 dispersed evenly; then measure 12mL of benzene and add it to the above-mentioned mixed liquid of polyethylene glycol and water, and mix evenly under magnetic stirring to obtain an emulsion. The emulsion is evenly divided into 2 parts as a mixed dispersion medium, and 10.1550 g (0.0209 mol) of bismuth nitrate Bi (NO 3 ) 3 ·5H 2 Colorless crystalline particles of O, magnetically stirred until uniformly dispersed, and obtained Bi(NO 3 ) 3 The mixed liquid; another part was added 2.6348g (0.0225mol) of ammonium metavanadate NH as a dispersed substance 4 VO 3 The white crystalline particles are heated in a water bath to 95°C to disperse them evenly, and the NH-conta...

Embodiment 2)

[0051] This example prepares BiVO 4 The rest of the method is the same as in Example 1, except that in step 3., the time for the reaction solution to carry out the hydrothermal reaction at 170° C. is 6 hours.

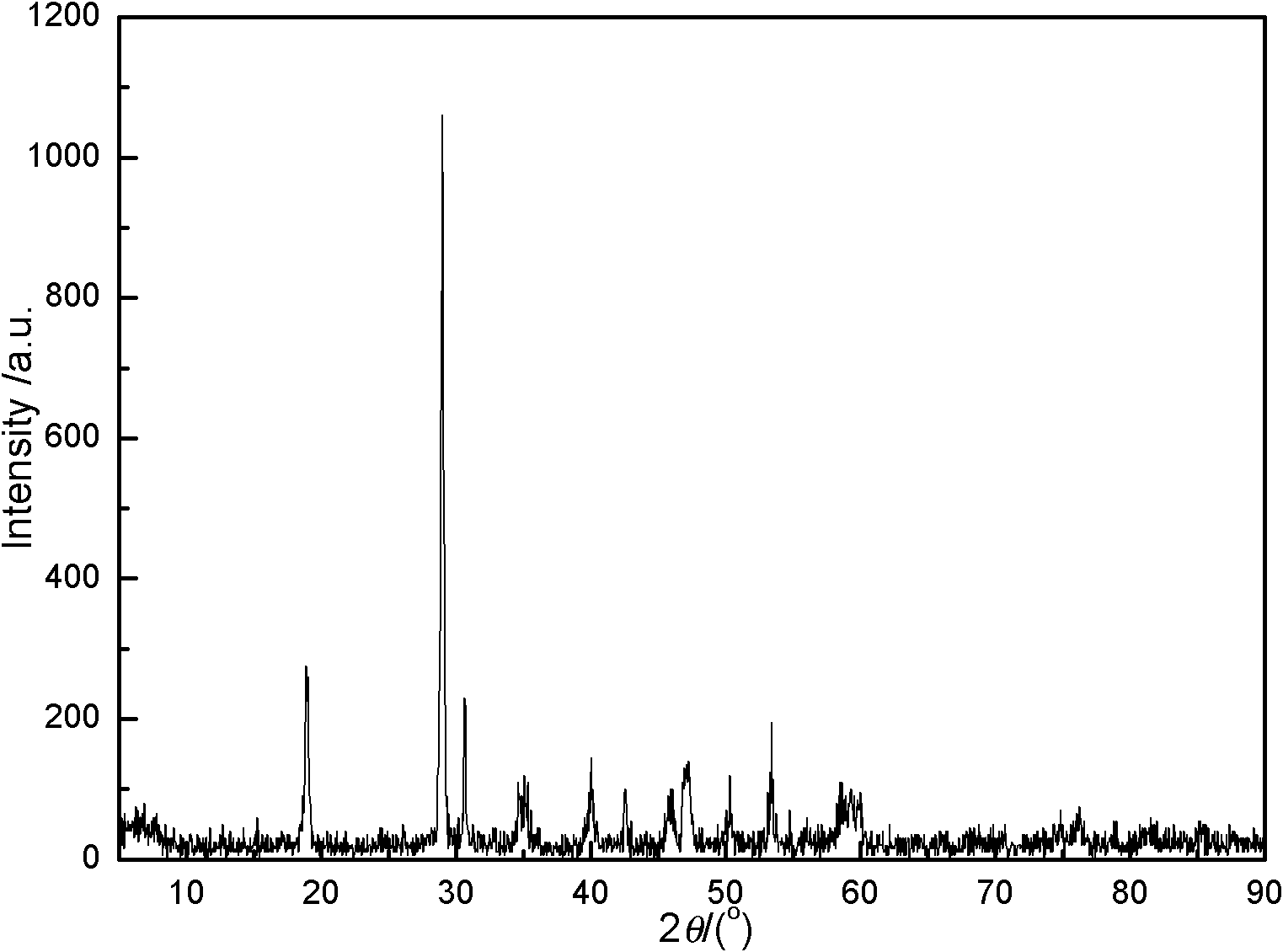

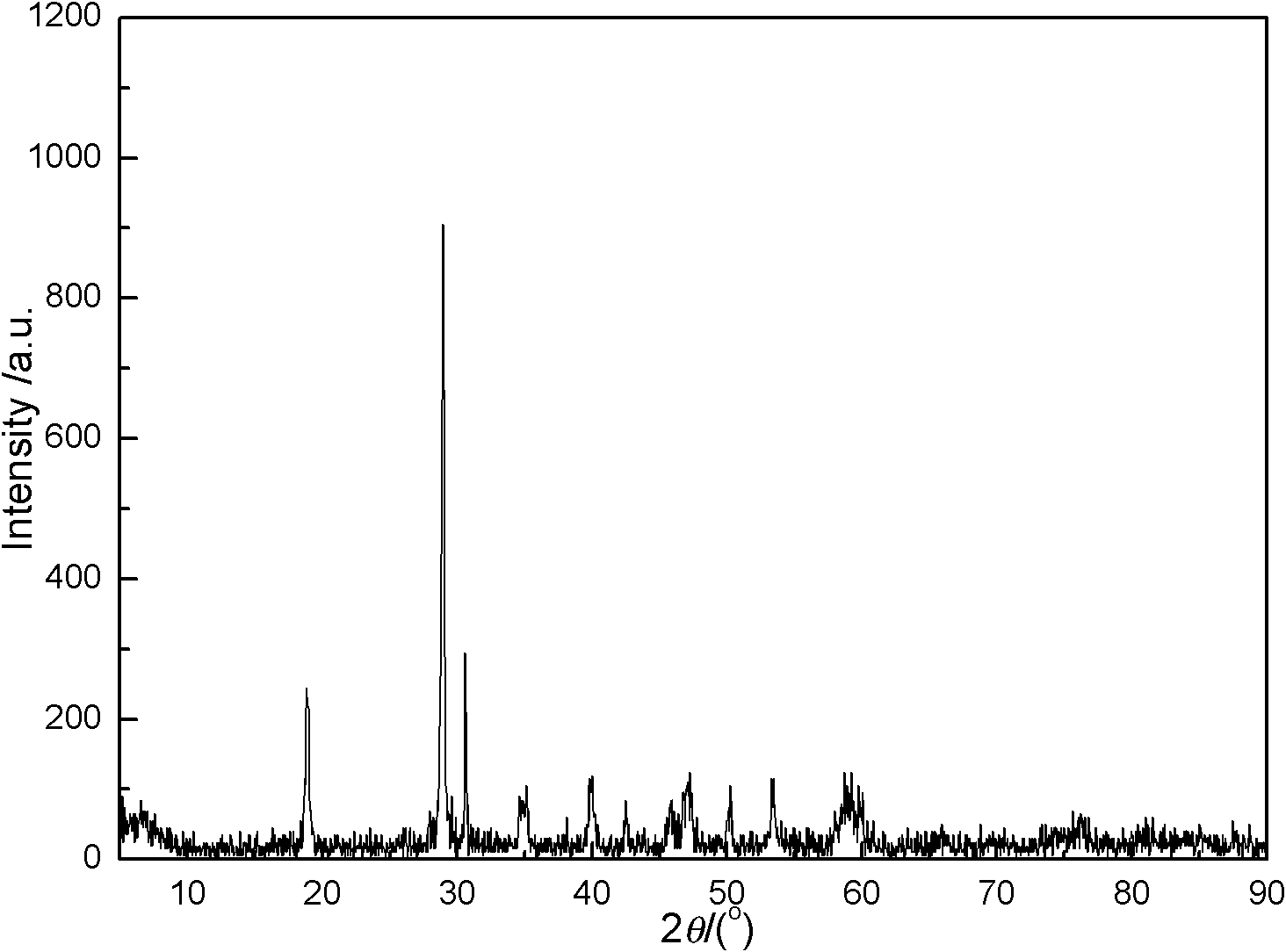

[0052] The X-ray powder diffraction pattern of the product is shown in image 3 , strong diffraction peaks appeared at the positions of 18.93°, 28.96°, 39.90° and 53.38°, and BiVO 4 The XRD standard card (JCPDF NO.14-0668) coincides, indicating that the product belongs to the monoclinic scheelite structure, and its unit cell parameters are a=0.5195nm, b=1.1701nm, c=0.5092nm, β=90.38 °. The intensity of diffraction peaks at other positions is weaker, and no other impurity phases appear, indicating that the purity of the sample is higher.

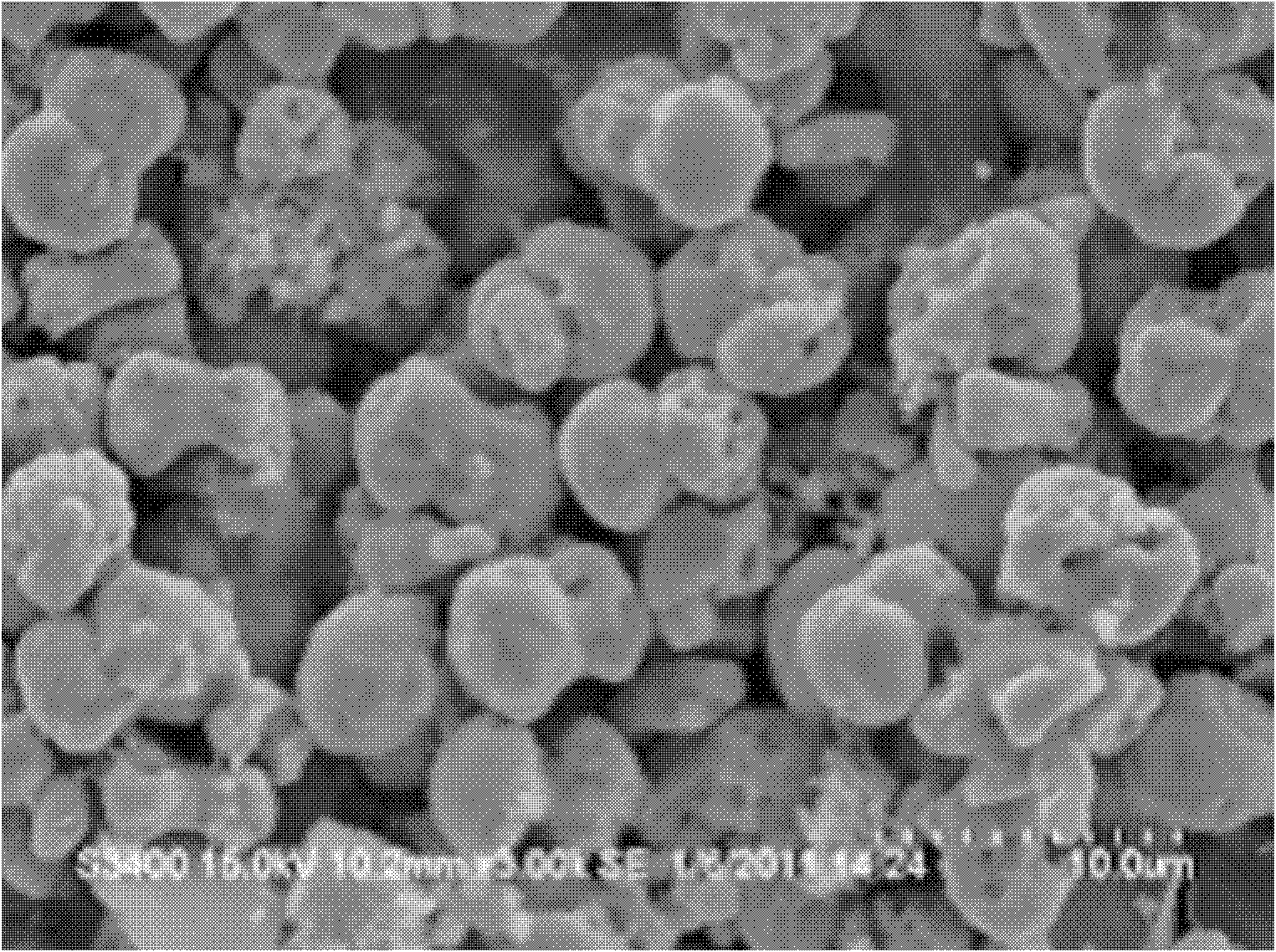

[0053] The SEM photo of the product is shown in Figure 4 , the product has a relatively uniform morphology and good dispersion. The SEM photo of the powder shows that the particles are dumbbell-shaped, and both ends of the dumbbe...

Embodiment 3)

[0056] This example prepares BiVO 4 The method all the other are identical with embodiment 1, difference is: in step 3., the time that reaction solution carries out hydrothermal reaction at 170 ℃ is 16 hours.

[0057] The SEM photo of the product is shown in Figure 5 , the SEM photo of the powder shows that the particles are dumbbell-shaped, and both ends of the dumbbell-shaped particles are cauliflower-shaped. The length of the particle is 6-12 μm, the maximum width of the head is 3-7 μm, and the width of the waist is 3-6 μm.

[0058] Detect the synthesized BiVO according to the method described in Example 1 4 Catalytic performance, the photocatalytic degradation rate of methylene blue is 91.36%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com