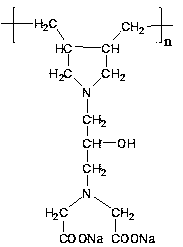

Macromolecule chelating agent and preparation method thereof

A technology of polymer chelating agent and epichlorohydrin, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of expanding application fields, easy access to raw materials, easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

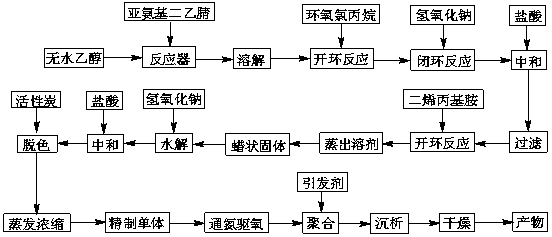

Embodiment 1

[0029] (1) According to the volume ratio of absolute ethanol and epichlorohydrin as 10:1, first add 158mL of absolute ethanol to a 500mL three-necked bottle with a reflux condenser and a mechanical stirrer, and then add 17.1g of imino di Acetonitrile was stirred until dissolved, then 15.8mL of epichlorohydrin was added dropwise, and reacted at 40°C for 6h;

[0030] (2) Keep the temperature at 40°C, add 14.4mL of NaOH solution with a mass percentage concentration of 45% to the solution in step (1) dropwise within 2h, continue to react for 1h after the dropwise addition, and then add 6.7mL of 6mol / L hydrochloric acid and excess NaOH, filtered to remove NaCl, then added 22.4mL diallylamine to the filtrate and continued the reaction at 70°C for 4h, distilled off the solvent to obtain 41.7g light yellow waxy solid;

[0031] (3) Add the solid obtained in step (2) to 365 mL of NaOH solution with a mass percent concentration of 4.5%, heat up to 95°C for hydrolysis for 0.5 h, add 12 mL...

Embodiment 2

[0033] (1) According to the volume ratio of absolute ethanol and epichlorohydrin as 15:1, first add 237mL of absolute ethanol to a 500mL three-necked bottle with a reflux condenser and a mechanical stirrer, and then add 18.1g of imino di Acetonitrile was stirred until dissolved, then 15.8mL epichlorohydrin was added dropwise, and reacted at 50°C for 5h;

[0034] (2) Keep the temperature at 50°C, add 13.3mL NaOH solution with a mass percentage concentration of 48% to the solution in step (1) dropwise within 2h, continue to react for 1h after the dropwise addition, and then add 6.7mL of 6mol / L hydrochloric acid and excess NaOH, filtered to remove NaCl, then added 23.6mL diallylamine to the filtrate to continue the reaction at 60°C for 4.5h, distilled off the solvent to obtain 43.6g light yellow waxy solid;

[0035] (3) Add the solid obtained in step (2) to 345 mL of NaOH solution with a mass percent concentration of 5%, heat up to 95° C. for hydrolysis for 1 h, add 12.7 mL of 6m...

Embodiment 3

[0037] (1) According to the volume ratio of absolute ethanol and epichlorohydrin as 20:1, first add 316mL of absolute ethanol to a 500mL three-necked bottle with a reflux condenser and a mechanical stirrer, then add 19g of iminodiacetonitrile Stir until dissolved, then add 15.8mL of epichlorohydrin dropwise, and react at 60°C for 4h;

[0038] (2) Keep the temperature at 60°C, add 12.6mL of 50% NaOH solution dropwise to the solution in step (1) within 2h, continue to react for 1h after the dropwise addition, and then add 6.7mL of 6mol / L hydrochloric acid and excess NaOH, filtered to remove NaCl, then added 24.9mL diallylamine to the filtrate and continued the reaction at 70°C for 4h, distilled off the solvent to obtain 45.6g light yellow waxy solid;

[0039] (3) Add the solid obtained in step (2) to 364 mL of NaOH solution with a mass percent concentration of 5%, heat up to 95° C. for hydrolysis for 1 h, add 13.3 mL of 6 mol / L hydrochloric acid to neutralize excess NaOH after c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com