Automatic generation method of cable bridge

An automatic generation, cable tray technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as cable tray waste, and achieve the effect of solving waste problems and avoiding errors and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

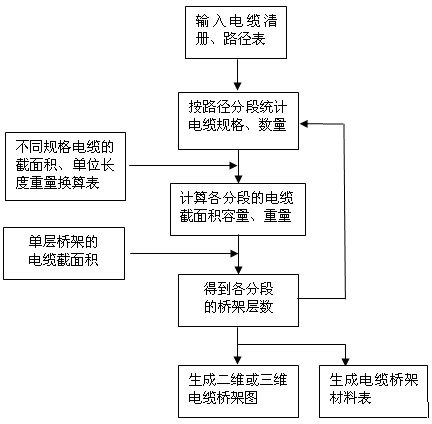

[0031] The method for automatically generating cable trays in this embodiment is applied in a power plant to generate a design drawing and a list of materials for cable trays in a certain area of the main powerhouse. The flow chart of its operation steps is as follows figure 1 shown.

[0032] This method is based on thermal control design technology and computer technology, with EXCEL VBA as the design platform, and specifically includes the following steps:

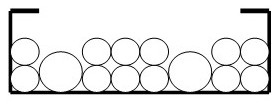

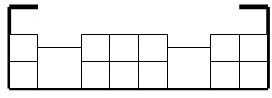

[0033] a. In the computer system, define the conversion table of cable specifications, cross-sectional area, and weight per unit length. As shown in Table 1, not all models are listed in the table, but only the cable models used in the example are listed. The calculation method for the cross-sectional area of the cable is to calculate the area of a square with the diameter of the cable as the side length. Schematic diagram of the arrangement of cables in the bridge frame in actual engineering. The actual shape o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com