Medicine for treating child influenza and preparation method thereof

A drug and children's technology, which is applied in the field of treating children's cold medicine and its preparation, can solve the problems of troublesome treatment and large volume of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

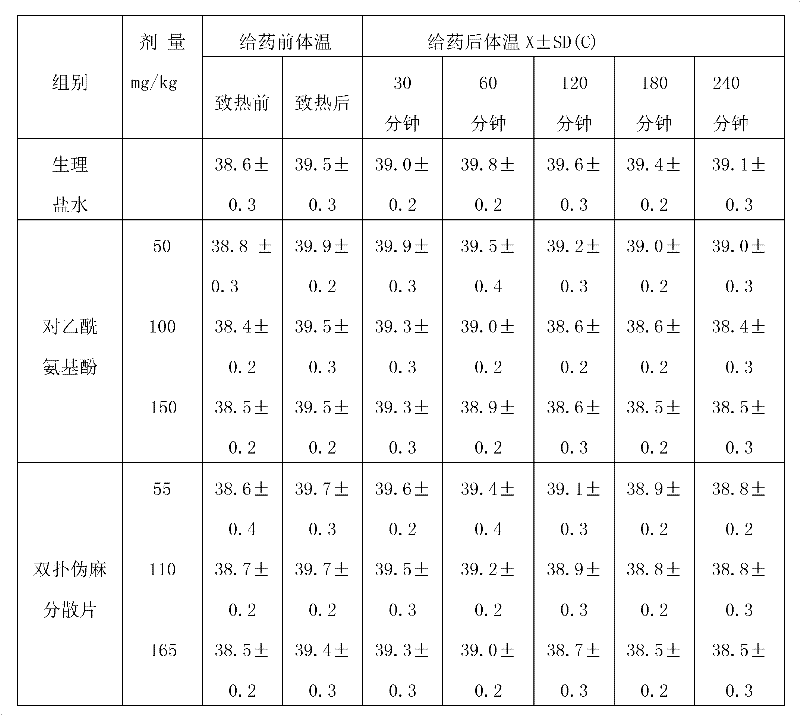

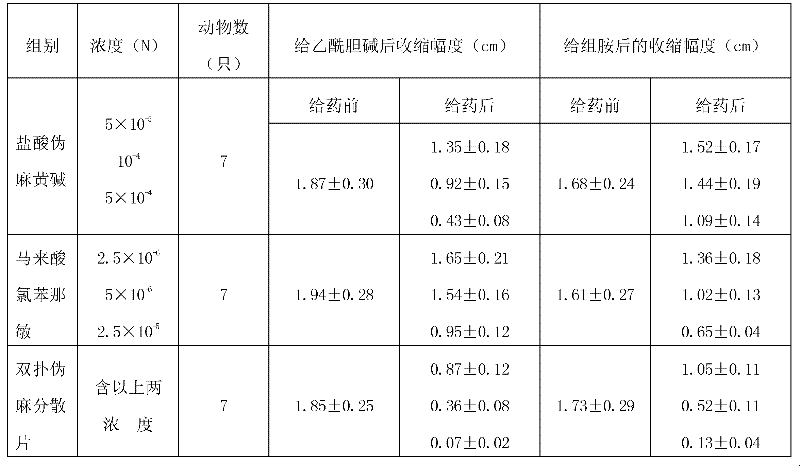

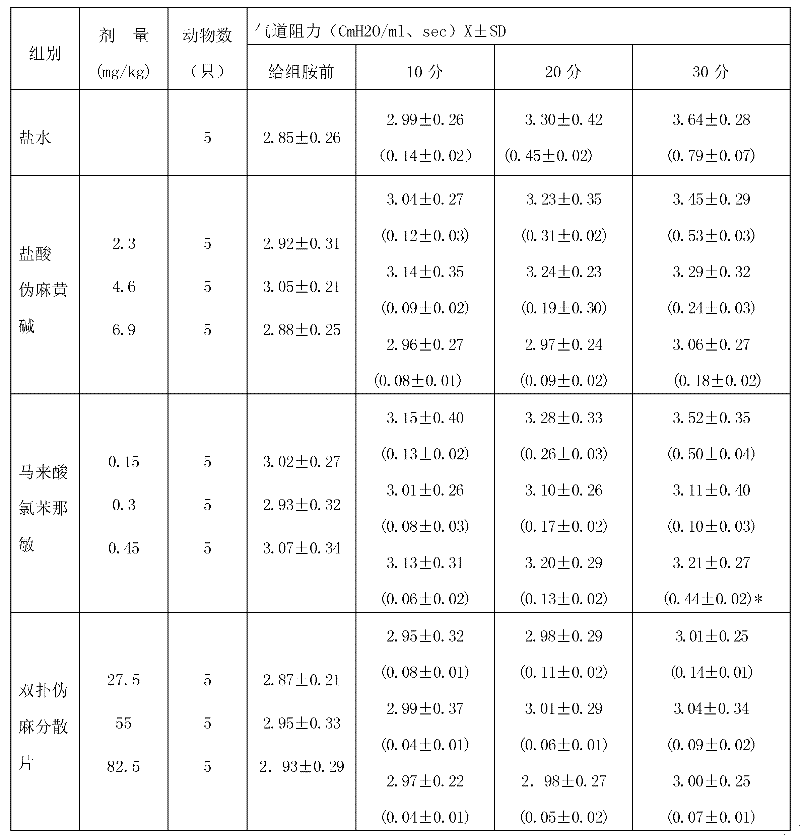

Examples

Embodiment 1

[0082] Weigh the raw materials according to the following ratio:

[0083] Paracetamol 80g, pseudoephedrine hydrochloride 7.5g, chlorpheniramine maleate 0.5g,

[0084] 44g of microcrystalline cellulose, 21.5g of starch, 8g of aspartame, 9g of sodium starch glycolate, 0.8g of magnesium stearate, 6.7g of 60% ethanol and 25g of 2% aqueous solution of sodium starch glycolate are used as auxiliary materials.

[0085] Specific preparation method:

[0086] 1) Paracetamol, pseudoephedrine hydrochloride, and chlorpheniramine maleate are respectively pulverized into fine powders for subsequent use;

[0087] 2) Mix chlorpheniramine maleate with acetaminophen and pseudoephedrine hydrochloride uniformly in an equal increment method;

[0088] 3) Weigh 24 g of microcrystalline cellulose, 19.5 g of starch, 8 g of aspartame, and 1 g of sodium starch glycolate, mix them uniformly, crush and sieve, and mix uniformly with the product obtained in step 2);

[0089] 4) Add 60% ethanol 6.7g and 2% ...

Embodiment 2

[0093] Weigh the raw materials according to the following ratio:

[0094] Acetaminophen 70g, pseudoephedrine hydrochloride 6g, chlorpheniramine maleate 0.3g,

[0095] 44g of microcrystalline cellulose, 21.5g of starch, 8g of aspartame, 9g of sodium starch glycolate, 0.8g of magnesium stearate, 6.7g of 60% ethanol and 25g of 2% aqueous solution of sodium starch glycolate are used as auxiliary materials.

[0096] Specific preparation method:

[0097] 1) Paracetamol, pseudoephedrine hydrochloride, and chlorpheniramine maleate are respectively pulverized into fine powders for subsequent use;

[0098] 2) Mix chlorpheniramine maleate with acetaminophen and pseudoephedrine hydrochloride uniformly in an equal increment method;

[0099] 3) Weigh 24 g of microcrystalline cellulose, 19.5 g of starch, 8 g of aspartame, and 1 g of sodium starch glycolate, mix them uniformly, crush and sieve, and mix uniformly with the product obtained in step 2);

[0100] 4) Add 60% ethanol 6.7g and 2% ...

Embodiment 3

[0104] Weigh the raw materials according to the following ratio:

[0105] Paracetamol 75g, pseudoephedrine hydrochloride 7g, chlorpheniramine maleate 0.4g,

[0106] 44g of microcrystalline cellulose, 21.5g of starch, 8g of aspartame, 9g of sodium starch glycolate, 0.8g of magnesium stearate, 6.7g of 60% ethanol and 25g of 2% aqueous solution of sodium starch glycolate are used as auxiliary materials.

[0107] Specific preparation method:

[0108] 1) Paracetamol, pseudoephedrine hydrochloride, and chlorpheniramine maleate are respectively pulverized into fine powders for subsequent use;

[0109] 2) Mix chlorpheniramine maleate with acetaminophen and pseudoephedrine hydrochloride uniformly in an equal increment method;

[0110] 3) Weigh 24 g of microcrystalline cellulose, 19.5 g of starch, 8 g of aspartame, and 1 g of sodium starch glycolate, mix them uniformly, crush and sieve, and mix uniformly with the product obtained in step 2);

[0111] 4) Add 60% ethanol 6.7g and 2% ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com