Copper-based nano catalyst for preparing high-carbon alcohol from synthetic gas as well as preparation method and application thereof

A nano-catalyst and high-carbon alcohol technology, applied in the preparation of hydroxyl compounds, organic compounds, physical/chemical process catalysts, etc., can solve the problems of unstable activity and selectivity, loss of catalyst additives, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

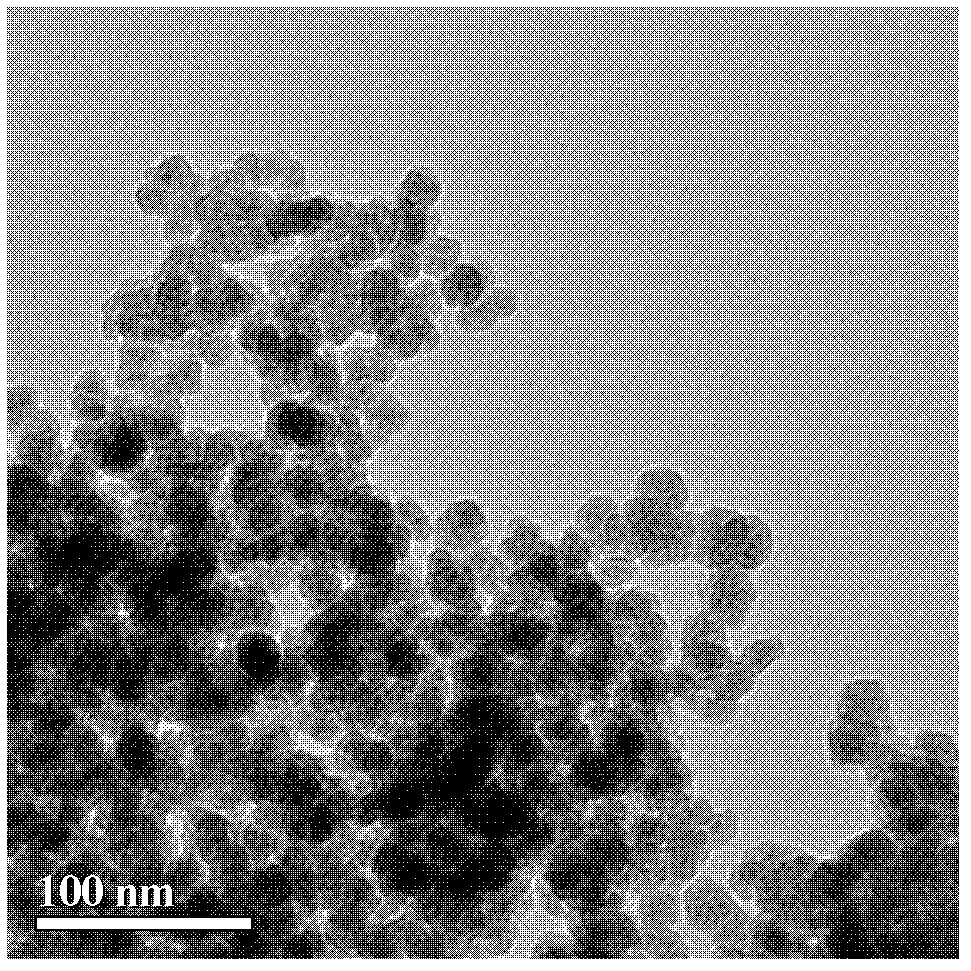

Image

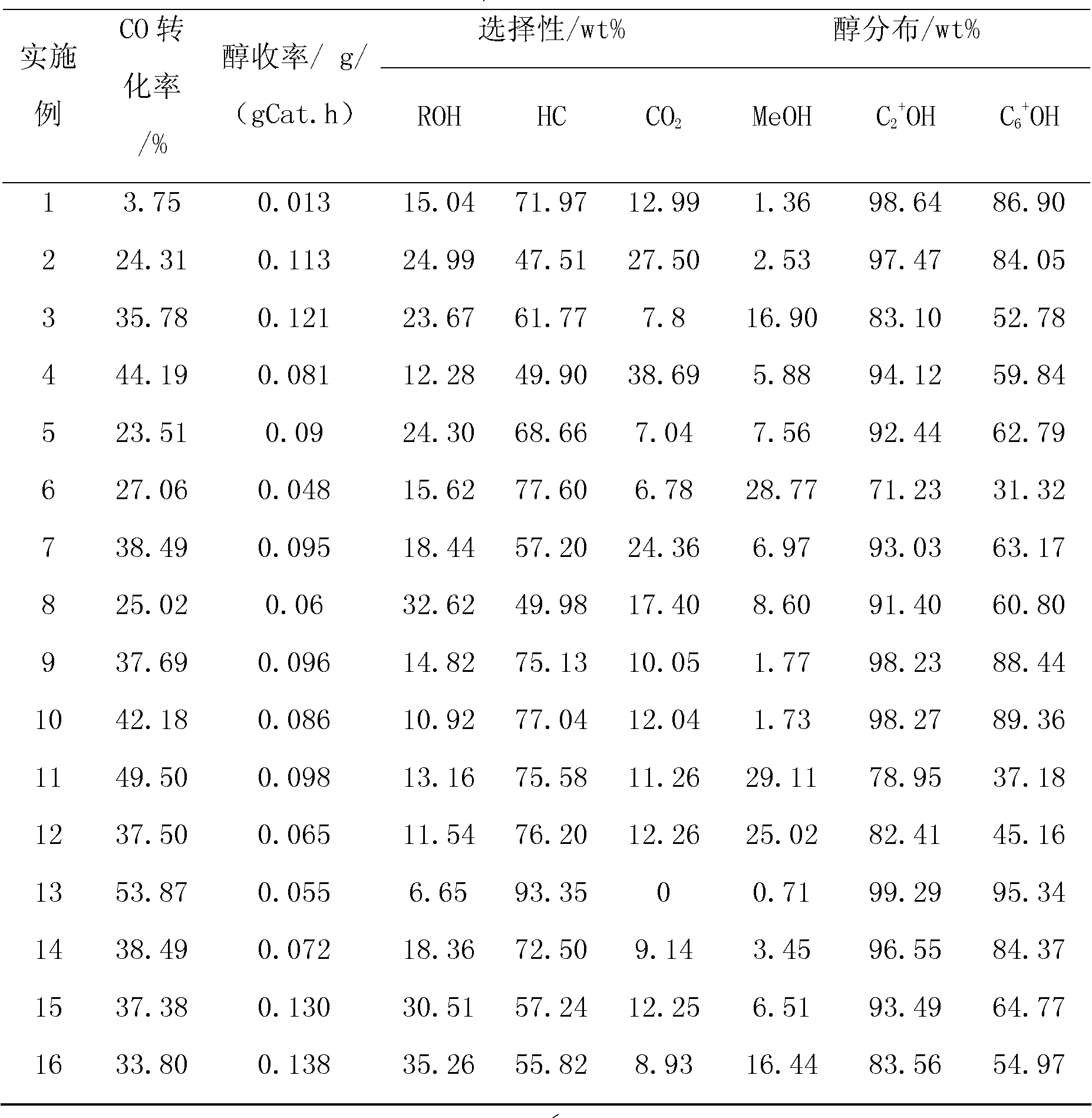

Examples

Embodiment 1

[0052] Cu(NO 3 ) 2 ·3H 2 O and Fe(NO 3 ) 3 9H 2 O is dissolved in ethylene glycol (EG) according to the Cu / Fe=3 / 2 ratio (molar ratio), so that the total metal ion concentration is 0.15mol / L to obtain a mixed metal solution, which is cooled in an ice-water bath. excess NaBH 4 Soluble in H 2 O and EG mixed solvent (H 2 The volume ratio of O and EG is 1 / 5), quickly drop the mixed metal solution, and stir for 10 minutes after dropping to complete the reduction. After cooling to room temperature, dilute with acetone and centrifuge. The resulting black solid was washed once with acetone, once with deoxygenated water, and twice with acetone, dried in an oven at 80°C to form a block, and then transferred to a tube furnace. 2 Dry at 300°C for 1 h under protection to obtain the catalyst. The reaction conditions for preparing higher alcohols from synthesis gas in a fixed-bed catalytic reaction device are as follows: 220°C, H 2 And the total pressure of CO is 6.0MPa, GHSV=6000h...

Embodiment 2

[0054] Cu(NO 3 ) 2 ·3H2 O and Fe(NO 3 ) 3 9H 2 O was dissolved in ethylene glycol (EG) according to the ratio of Cu / Fe=3 / 1, so that the total metal ion concentration was 0.13mol / L to obtain a mixed metal solution, which was cooled in an ice-water bath. excess NaBH 4 Soluble in H 2 O and EG mixed solvent (H 2 The volume ratio of O and EG is 1 / 5), quickly drop the mixed metal solution, and stir for 10 minutes after dropping to complete the reduction. After cooling to room temperature, add deoxygenated water to dilute, and centrifuge. The resulting black solid was washed once with deoxygenated water, then once with ethanol, dried at room temperature into a block, and then transferred to a tube furnace for N 2 Dry at 150°C for 1 hour under protection to obtain the catalyst. The reaction conditions for preparing higher alcohols from synthesis gas in a fixed-bed catalytic reaction device are as follows: 210°C, H 2 And the total pressure of CO is 6.0MPa, GHSV=6000h -1 , H ...

Embodiment 3

[0056] Cu(NO 3 ) 2 ·3H 2 O and Fe(NO 3 ) 3 9H 2 O was dissolved in ethylene glycol (EG) according to the ratio of Cu / Fe=3 / 1, so that the total metal ion concentration was 0.13mol / L to obtain a mixed metal solution, which was cooled in an ice-water bath. excess NaBH 4 Soluble in H 2 O and EG mixed solvent (H 2 The volume ratio of O and EG is 1 / 5), quickly drop the mixed metal solution, and stir for 10 minutes after dropping to complete the reduction. After cooling to room temperature, add deoxygenated water to dilute, and centrifuge. Gained black solid was washed 2 times with deoxygenated water, then 3 times with ethanol, dried at room temperature into a block, and then transferred to a tube furnace for N 2 Dry at 150°C for 2 hours under protection to obtain the catalyst. The reaction conditions for preparing higher carbon alcohols from synthesis gas in a fixed bed catalytic reaction device are as follows: 240°C, H 2 And the total pressure of CO is 6.0MPa, GHSV=6000h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com