Modified anion exchange resin with double long carbon chains and preparation method and application thereof

A technology for exchanging resins and anions, which is applied in the field of double-long carbon chain modified anion exchange resins and its preparation, which can solve the problems of obvious disadvantages of liquid caustic soda, difficulty in continuous production and retention, etc., and achieve increased steric hindrance effects and simplified Subsequent separation process to achieve the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a) Pretreatment of polystyrene tertiary amine weak base resin:

[0030] The impurities on the surface of the polystyrene tertiary amine weak base resin were washed with water, loaded into a glass exchange column, ion-exchanged with 5% HCl overnight, and then washed with water until the pH was close to 7. Ion-exchange with 1mol / L NaOH in a glass exchange column overnight, and wash with water until the pH is close to 7. Dry in vacuum for 6 hours.

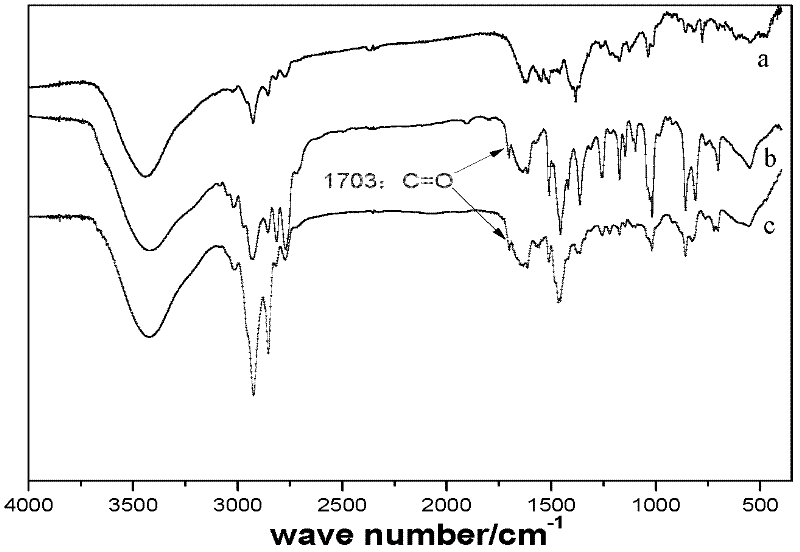

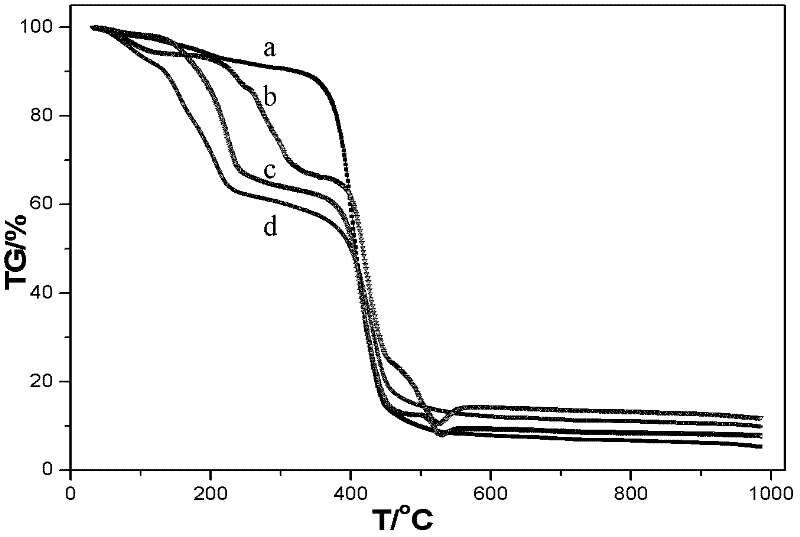

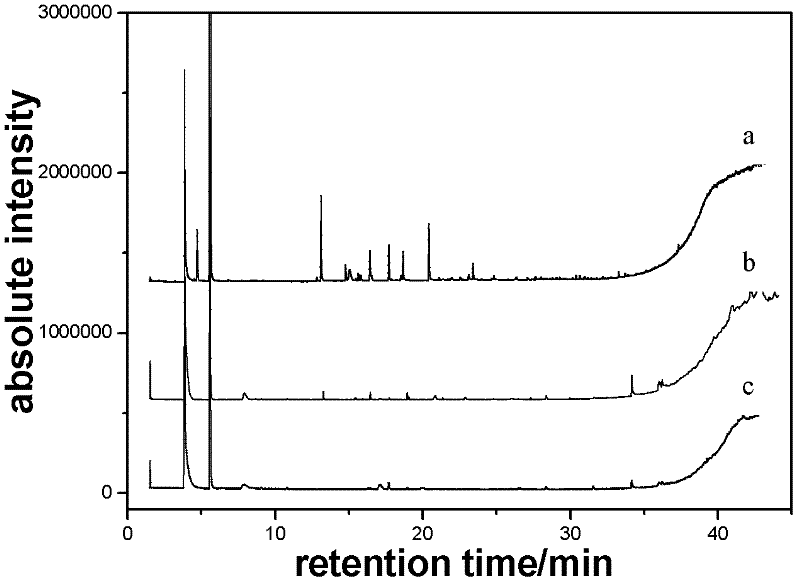

[0031] b) Friedel-Crafts reaction to synthesize stearyl tertiary amine weak base resin:

[0032] Take 5 g of pretreated polystyrene tertiary amine weak base resin, soak it in 200 ml of nitrobenzene, and put it into a 1000 ml three-necked bottle. Add 5g of anhydrous AlCl at 0°C 3 And 20.2g stearyl chloride, stir, and carry out nitrogen protection. After reacting for 32 hours, filter out the resin, and wash with 100ml, 1N hydrochloric acid, 300ml deionized water, 300ml H 2 Wash with O / THF mixed solution and 300ml THF, and th...

Embodiment 2

[0036] a) Pretreatment of polystyrene tertiary amine weak base resin:

[0037]The impurities on the surface of the polystyrene tertiary amine weak base resin were washed with water, loaded into a glass exchange column, ion-exchanged with 5% HCl overnight, and then washed with water until the pH was close to 7. Ion-exchange with 1mol / L NaOH in a glass exchange column overnight, and wash with water until the pH is close to 7. Dry in vacuum for 6 hours.

[0038] b) Friedel-Crafts reaction to synthesize stearyl tertiary amine weak base resin:

[0039] Take 5g of the pretreated resin, soak it in 200ml nitrobenzene, and put it into a 1000ml three-neck bottle. Add 5g of anhydrous AlCl at 25°C 3 And 20.2g stearyl chloride, stir, and carry out nitrogen protection. After reacting for 32 hours, filter out the resin, and wash with 100ml, 1N hydrochloric acid, 300ml deionized water, 300ml H 2 Wash with O / THF mixed solution and 300ml THF, and then vacuum-dry for 2 hours to obtain octad...

Embodiment 3

[0043] a) Pretreatment of polystyrene tertiary amine weak base resin:

[0044] The impurities on the surface of the polystyrene tertiary amine weak base resin were washed with water, loaded into a glass exchange column, ion-exchanged with 5% HCl overnight, and then washed with water until the pH was close to 7. Ion-exchange with 1mol / L NaOH in a glass exchange column overnight, and wash with water until the pH is close to 7. Dry in vacuum for 6 hours.

[0045] b) Friedel-Crafts reaction to synthesize stearyl tertiary amine weak base resin:

[0046] Take 5g of the pretreated resin, soak it in 200ml carbon disulfide, and put it into a 1000ml three-neck bottle. Add 5g of anhydrous AlCl at 0°C 3 And 20.2g stearyl chloride, stir, and carry out nitrogen protection. After reacting for 32 hours, filter out the resin, and wash with 100ml, 1N hydrochloric acid, 300ml deionized water, 300ml H 2 Wash with O / THF mixed solution and 300ml THF, and then vacuum-dry for 2 hours to obtain o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com