Titanium dioxide nanotube array-carbon nanotube-hydroxyapatite biological composite coating and preparation thereof

A nanotube array, hydroxyapatite technology, applied in the intersection of materials science and biomedicine, can solve the problem of insignificant overall effect, reduced biological activity and compatibility of the coating, and low bonding force between the coating and the substrate interface, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The proportion of the carbon nanotube-hydroxyapatite composite powder is (wt%): 90% of the hydroxyapatite powder, and 10% of the carbon nanotube.

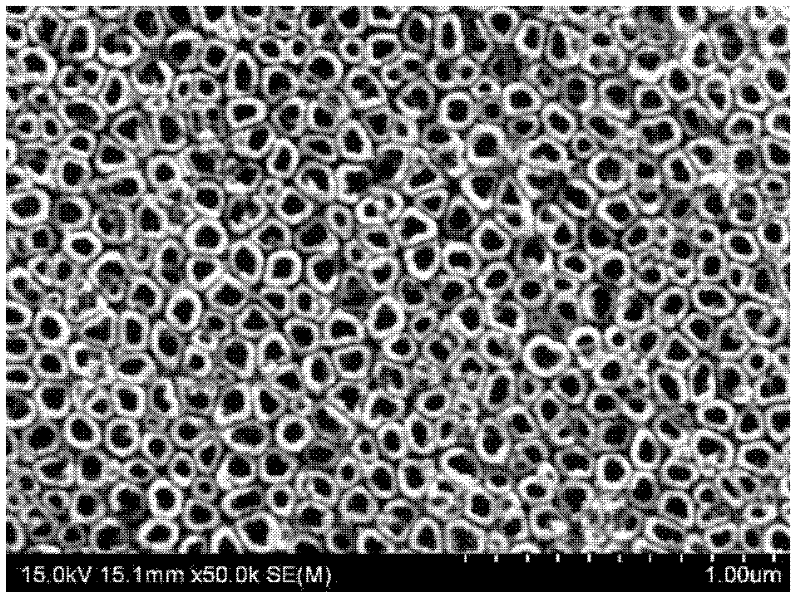

[0025] (1) Use metal platinum as the cathode, and use a titanium sheet with a smooth and traceless surface as the anode, anodize it in a 0.5wt% hydrofluoric acid solution for 20 minutes, then clean the titanium sheet and heat treat it at 450 ° C for 2 hours to obtain a surface with titanium dioxide nanoparticles. Titanium substrate for tube arrays. Scanning electron microscope observation of its surface morphology as figure 1 Shown (its tube diameter is about 100nm).

[0026] (2) Accurately weigh 63.466 grams of Ca (NO 3 ) 2 4H 2 O, 21.300 g (NH 4 ) 2 HPO 4 , were poured into 250ml of distilled water to make a solution. Accurately weigh 3 g of the treated carbon nanotubes, add Ca(NO 3 ) 2 solution, ultrasonically disperse for 30min, and transfer it to a three-necked flask, adjust the pH value to 10 with ammonia wat...

Embodiment 2

[0031] The proportion of the carbon nanotube-hydroxyapatite composite powder is (wt%): 80% of the hydroxyapatite powder and 20% of the carbon nanotube.

[0032] (1) Use metal platinum as the cathode, and use a titanium sheet with a smooth and traceless surface as the anode, anodize it in a 0.5wt% hydrofluoric acid solution for 20 minutes, then clean the titanium sheet and heat treat it at 450 ° C for 2 hours to obtain a surface with titanium dioxide nanoparticles. Titanium substrate for tube arrays.

[0033](2) Accurately weigh 56.414g of Ca(NO 3 ) 2 4H 2 O, 18.932 g (NH 4 ) 2 HPO 4 , were poured into 250ml of distilled water to make a solution. Accurately weigh 3 g of the treated carbon nanotubes, add Ca(NO 3 ) 2 solution, ultrasonically dispersed for 30 min, and transferred to a three-necked flask. Use ammonia water to adjust the pH value to 10-13, and (NH 4 ) 2 HPO 4 The solution was dripped into a three-necked flask under constant stirring for 1 hour, and kept ...

Embodiment 3

[0038] The proportion of the carbon nanotube-hydroxyapatite composite powder is (wt%): 70% of the hydroxyapatite powder, and 30% of the carbon nanotube.

[0039] (1) Use metal platinum as the cathode, and use a titanium sheet with a smooth and traceless surface as the anode, anodize it in a 0.5wt% hydrofluoric acid solution for 20 minutes, then clean the titanium sheet and heat treat it at 450 ° C for 2 hours to obtain a surface with titanium dioxide nanoparticles. Titanium substrate for tube arrays.

[0040] (2) Accurately weigh 49.363 grams of Ca(NO 3 ) 2 4H 2 O, 16.566 g (NH 4 ) 2 HPO 4 , were poured into 250ml of distilled water to make a solution. Accurately weigh 3 g of the treated carbon nanotubes, add Ca(NO 3 ) 2 solution, ultrasonically dispersed for 30 min, and transferred to a three-necked flask. Use ammonia water to adjust the pH value to 10-13, and (NH 4 ) 2 HPO 4 The solution was dripped into the reaction vessel under constant stirring for 1 hour, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com