Yttrium-element autoclaved aerated concrete block and preparation method thereof

A technology of concrete block and aerated concrete, applied in the field of building materials, can solve the problems of increasing foundation treatment and construction costs, wasting raw materials, long production cycle, etc. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 The yttrium element sand aerated concrete block is composed of the following raw materials in weight ratio:

[0057] 55 parts of sand, 0.03 parts of yttrium oxide, 28 parts of lime, 11 parts of cement, 2 parts of gypsum, 0.8 parts of aluminum powder, and 2 parts of calcium-based bentonite.

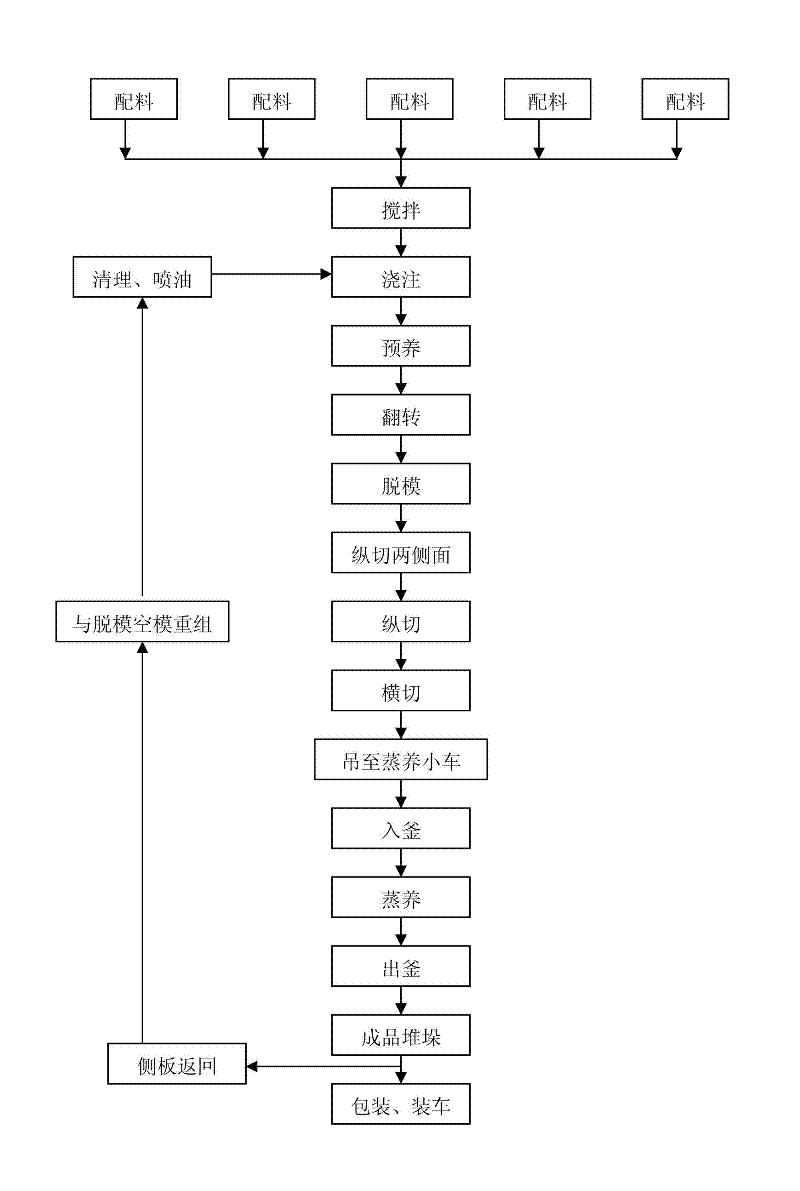

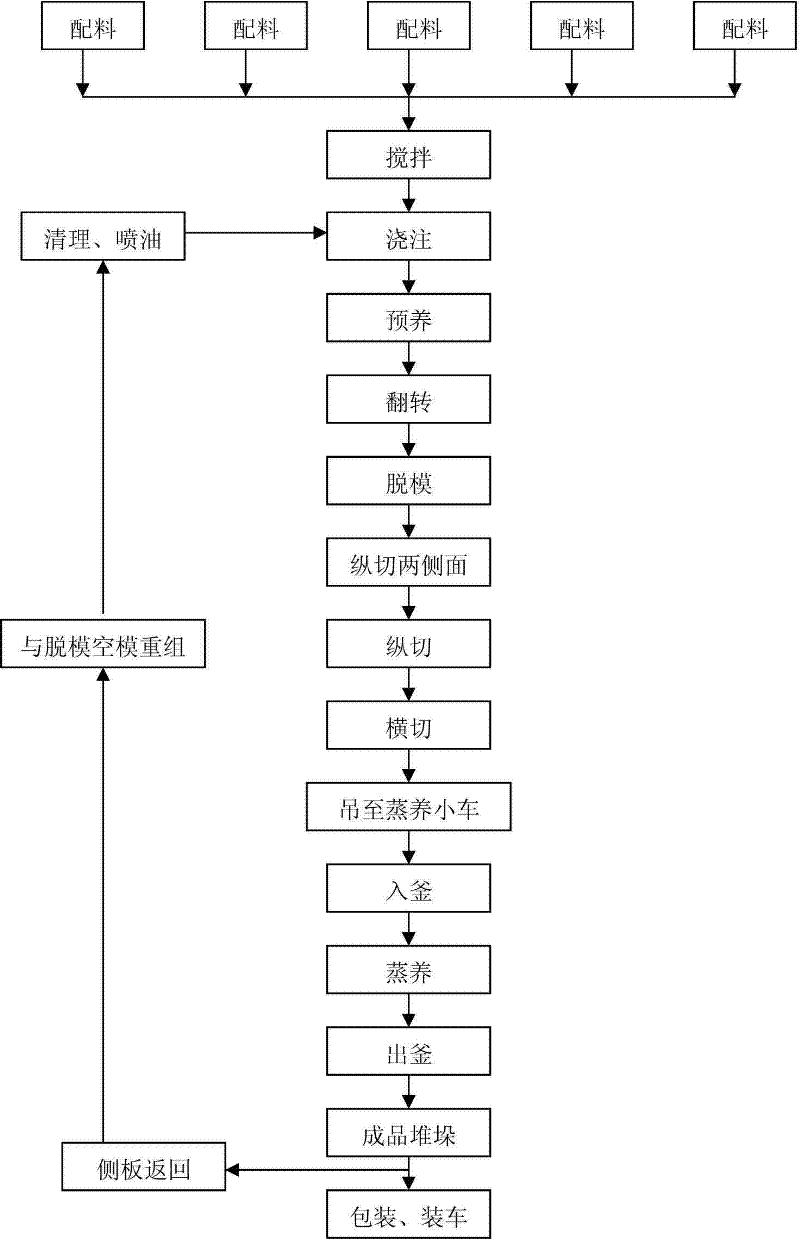

[0058] Its preparation method is as figure 1 Shown:

[0059] (1) Raw material processing;

[0060] ① Process the sand until it passes through a 0.080mm square hole sieve, with a sieve allowance of ≤15%, and stack it for use;

[0061] ② Lime is processed until it passes through a 0.080mm square hole sieve, the sieve allowance is ≤15%, the digestion speed (min) is 5-15, the digestion temperature (°C) is 60-90, and the undigested residue (%) is ≤10;

[0062] ③Calcium-based bentonite is processed until it passes through a 300-mesh sieve, and the sieve allowance is ≤1%;

[0063] ④ Yttrium oxide is a commercially available product and can be used directly;

[0064] ⑤ Cement...

Embodiment 2

[0100] Example 2 The yttrium element sand aerated concrete block is composed of the following raw materials in weight ratio:

[0101] 70 parts of sand, 0.06 parts of yttrium oxide, 23 parts of lime, 6 parts of cement, 6 parts of gypsum, 1.2 parts of aluminum powder, and 7 parts of calcium-based bentonite.

[0102] Its preparation method is with embodiment 1.

[0103] After testing, the average compressive strength of this product is 5.0MPa, which is 1.4 times of the GB11968-2006 standard of "Steam Pressurized Concrete Block", and the minimum value of a single group is 4.6MPa, which is 1.6 times of the above standard.

Embodiment 3

[0104] Example 3 The yttrium element sand aerated concrete block is composed of the following raw materials, in weight ratio:

[0105] 62 parts of sand, 0.03 parts of yttrium oxide, 25 parts of lime, 9 parts of cement, 4 parts of gypsum, 0.9 parts of aluminum powder, and 2 parts of calcium-based bentonite.

[0106] Its preparation method is with embodiment 1.

[0107] After testing, the average compressive strength of this product is 5.6MPa, which is 1.6 times of the GB11968-2006 standard of "Steam Pressurized Concrete Blocks", and the minimum value of a single group is 5.2MPa, which is 1.5 times of the above standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com