Granular preparation for promoting rice tillering

A granule preparation and rice technology, applied in the field of granule preparations to promote rice tillering, can solve the problems of low rice quality and harvesting difficulties, and achieve the effects of well-developed root system, good yield increase, and prevention of stiff seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

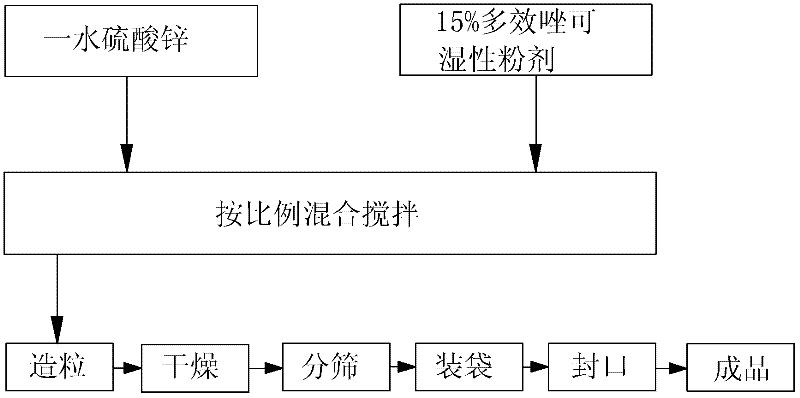

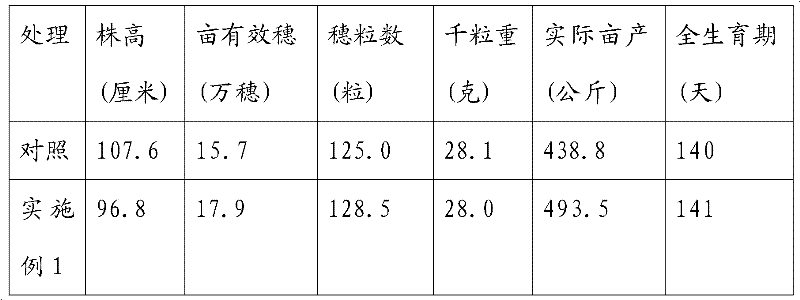

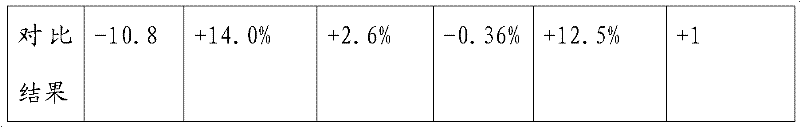

[0023] 1. Granule production method (please refer to figure 1 )

[0024] (1) Get 65 parts of zinc sulfate monohydrate as trace element fertilizer, 15% paclobutrazol wettable powder (it is processed by 95% paclobutrazol former medicine and suitable auxiliary agent and filler. National standard stipulates that in 15% paclobutrazol wettable powder Pure paclobutrazol mass percentage is 15%) 25 parts, according to above-mentioned weight ratio batching, mix, pass ≥ 70 mesh sieves, the powder after mixing sieving is sent to granulator, and described granulator can be spherical body granulation machine.

[0025] (2) Use a high-pressure pump to send water to the atomizing head of the granulator, and start the granulator at the same time for granulation.

[0026] (3) The shaped particles are sent to drying equipment for drying, and the drying equipment can be a hot air blower, a drying bed, etc.

[0027] (4) Sieve the dried granular product and pack it into bags. The spherical produc...

Embodiment 2

[0039] Take 75 parts of trace element fertilizer zinc sulfate monohydrate and 15 parts of 15% paclobutrazol wettable powder respectively by weight, and set aside.

[0040] Its preparation method is the same as that of Example 1 and will not be repeated here.

[0041] In 2011, a comparative test was carried out between the application of Example 2 and no application (control) on the middle rice "Liangyoupeijiu", and the results are as follows:

[0042]

[0043] As can be seen from the above table, after using the granule preparation of Example 2, compared with no application, the effective panicle is increased by 10.4%, the yield is increased by 10.1%, and the plant height is reduced by 7.2 centimeters.

Embodiment 3

[0045] Take 70 parts of trace element fertilizer zinc sulfate monohydrate and 21 parts of 15% paclobutrazol wettable powder respectively by weight, and set aside.

[0046] Its preparation method is the same as that of Example 1 and will not be repeated here.

[0047] In 2011, the application of Example 3 and no application (control) on the middle rice "Yangliangyou No. 6" was used as a comparative test, and the results were as follows:

[0048]

[0049] As can be seen from the above table, after using the granule preparation of Example 3, compared with no application, the effective panicle is increased by 14.2%, the yield is increased by 14.0%, and the plant height is reduced by 9.6 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com