Nano-structure controllable oligomerized benzophenanthrene and synthesis method thereof

A nanostructure and synthesis method technology, applied in chemical instruments and methods, condensation hydrocarbon production with dehydrocarbons, organic chemistry, etc., can solve the problems of poor photoelectric performance, high price, low yield, etc., and solve difficult Processing and synthesis of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] A method for synthesizing oligotriphenylene with controllable nanostructure, specifically comprising the following steps:

[0091] (1) Accurately weigh 115mg (0.5mmol) of triphenylene and dissolve in 50mL of dichloromethane to form a 0.01mol / L triphenylene monomer solution;

[0092] (2) According to the molar ratio of oxidant and triphenylene monomer of 20:1, weigh 1622 mg (10 mmol) of anhydrous ferric chloride and dissolve it in 75 mL of nitromethane to form an oxidant solution;

[0093] (3) After blending the oxidizing agent solution and the monomer solution, shake it violently for a while and then vibrate ultrasonically for 30 minutes, then place it in a water bath at a constant temperature, and react with magnetic stirring for 48 hours to obtain oligotriphenylene with a controllable nanostructure Crude reaction solution;

[0094] (4) After taking out the reaction liquid, control the rotation speed to 3000~4500r / min, centrifuge and settle for 30~60 minutes to obtain...

Embodiment 2

[0109] A method for synthesizing oligotriphenylene with controllable nanostructure, specifically comprising the following steps:

[0110] Chlorobenzene was used instead of dichloromethane, and the others were the same as in Example 1, and brown powdery oligotriphenylene with controllable nanostructure was finally obtained.

Embodiment 3

[0112] A method for synthesizing oligotriphenylene with controllable nanostructure, specifically comprising the following steps:

[0113] Nitrobenzene was substituted for dichloromethane, and the others were the same as in Example 1, finally obtaining a brown powdery oligotriphenylene with a controllable nanostructure.

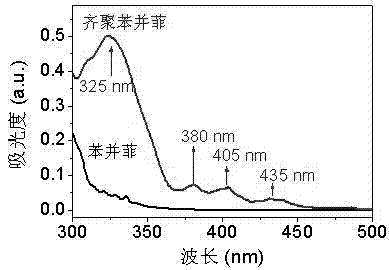

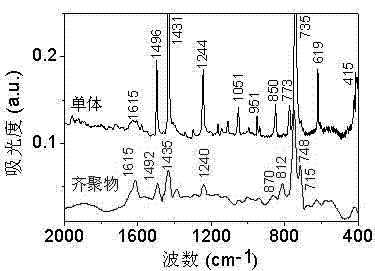

[0114] The nano-morphology of the oligomerized triphenylene obtained in the above-mentioned embodiment 1, embodiment 2 and embodiment 3 is shown in Figure 6 , Figure 7 and Figure 8 . When dichloromethane, chlorobenzene and nitrobenzene are used as solvents for triphenanthrene monomers, the diameters of the obtained oligomerized triphenanthrene nanofibers are 50 nm, 80 nm and 120 nm, respectively. The use of dichloromethane as a solvent enables relatively small diameters to be formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com