Method for producing methyl heptenone

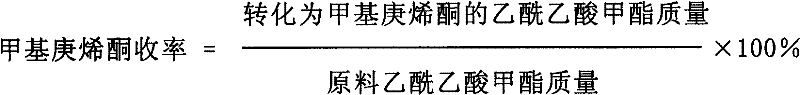

A technology of methyl heptenone and methyl butenol, which is applied in the field of synthesis of methyl heptenone, can solve the problems such as the inability to increase the yield, and achieve the effect of increasing the yield and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

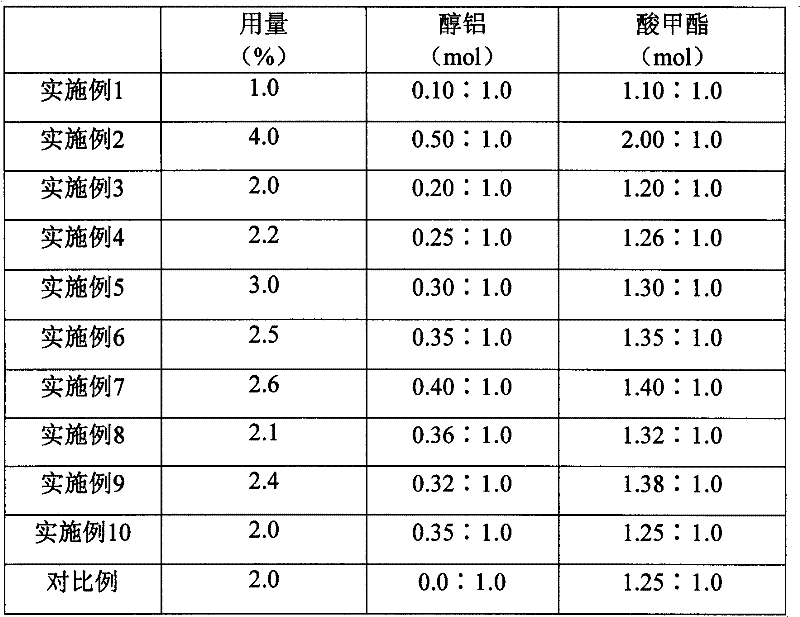

Embodiment 1~10

[0019] The reaction is carried out in a reactive distillation device, which is composed of a reactor and a rectification column. The reactor is a 1000ml glass reactor with a three-neck flask. The left and right sides are respectively the raw material inlet and the temperature measuring thermometer socket. The middle top is connected to the rectification column. The theoretical plate number of the rectification column is 18. Condensation and reflux devices at the vent and outlet.

[0020] First add 100 grams of methyl heptenone and an appropriate amount of catalyst into the reactor, heat the reactor to 140-160 ° C, and then maintain the temperature to continuously pump the prepared methyl butenol and methyl acetoacetate solution into the reaction The device reacts. The reaction pressure is normal pressure, and the reflux ratio of rectification is controlled. The carbon dioxide produced by the reaction is discharged through the vent at the top of the rectification column, and ...

Embodiment 11

[0029] A method for producing methyl heptenone, the raw material methyl butenol and methyl acetoacetate are placed in a reactor, the molar ratio of methyl butenol and methyl acetoacetate is 1.1:1, and the reaction temperature is 140°C , the reaction time is 5 hours, the catalyst that adopts is aluminum isopropoxide / diethanolamine composite catalyst, wherein the consumption of aluminum isopropoxide catalyst is 1% of the methyl acetoacetate feeding quality, the mol ratio of diethanolamine / aluminum isopropoxide The ratio is 0.1:1, and high-purity methyl heptenone is prepared by catalytic transesterification and Caroll reaction.

Embodiment 12

[0031] A method for producing methyl heptenone, the raw material methyl butenol and methyl acetoacetate are placed in a reactor, the molar ratio of methyl butenol and methyl acetoacetate is 1.2:1, and the reaction temperature is 146°C , the reaction time is 8 hours, the catalyst that adopts is aluminum isopropoxide / diethanolamine composite catalyst, wherein the consumption of aluminum isopropoxide catalyst is 2% of the methyl acetoacetate feeding quality, the mol ratio of diethanolamine / aluminum isopropoxide The ratio is 0.2:1, and high-purity methyl heptenone is prepared by catalytic transesterification and Caroll reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com