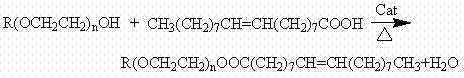

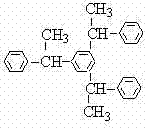

Preparation method of triphenylethylene phenol polyoxyethylene ether oleate

A technology of polyoxyethylene ether oleate and tristyryl phenol is applied in the field of preparation of tristyryl phenol polyoxyethylene ether oleate, which can solve problems such as troublesome product purification and environmental pollution, and achieves equipment investment and energy efficiency. Consumption saving, cost reduction, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 200 parts of tristyrene phenol polyoxyethylene ether (10) and 67 parts of oleic acid by weight into a 500ml flask, add 0.8 parts of calcium methanesulfonate catalyst under stirring, slowly raise the temperature, and separate water in time under the condition of nitrogen flow , kept at 140° C. for 2.0 hours, then cooled to 60° C. and discharged, and the acid conversion rate was 93.2%. This embodiment has the characteristics of reasonable process, simple operation, stable product, short reaction cycle and good usability.

Embodiment 2

[0020] Add 200 parts of tristyrene phenol polyoxyethylene ether (18) and 44.6 parts of oleic acid by weight into a 500ml flask, add 1.7 parts of calcium methanesulfonate catalyst under stirring, slowly raise the temperature, and separate water in time under the condition of nitrogen flow , kept at 160° C. for 2.8 hours, then cooled to 60° C. and discharged, and the acid conversion rate was 97.0%. This embodiment has the characteristics of reasonable process, simple operation, stable product, short reaction cycle and good usability.

Embodiment 3

[0022] Add 200 parts of tristyrene phenol polyoxyethylene ether (13) and 56.9 parts of oleic acid by weight into a 500ml flask, add 1.0 parts of zinc methanesulfonate catalyst under stirring, slowly raise the temperature, and separate water in time under the condition of nitrogen flow , kept at 150° C. for 1.5 hours under the reaction condition, then cooled to 60° C. and discharged, and the conversion rate of the acid was 95.0%. This embodiment has the characteristics of reasonable process, simple operation, stable product, short reaction cycle and good usability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com