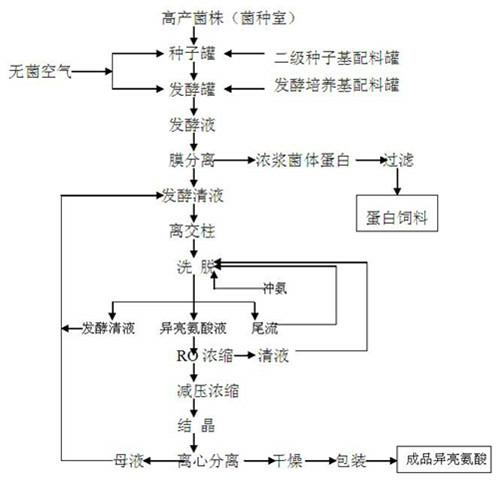

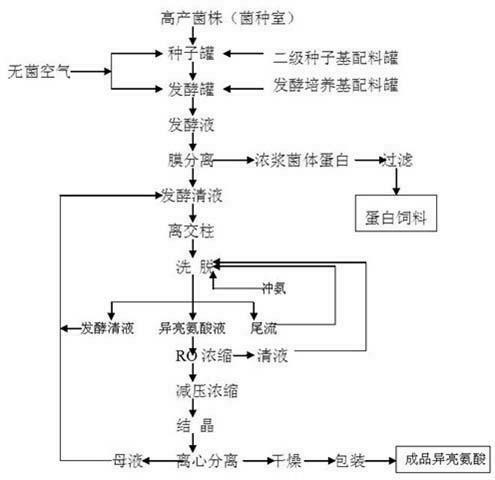

Isoleucine fermenting process

A technology of isoleucine and fermentation process, applied in the field of isoleucine fermentation process, can solve the problems of continuous, low level of automation, low level, high yield but not good harvest, etc., to reduce fermentation cost and extraction cost, and reduce metabolism Formation of by-products, favorable effect on product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] at 50m 3 Fermenter and 7 m 3 In the practice of seed tank production, the operation is as follows:

[0032] (1) Cultivate strains

[0033] Select and breed high-yield strains grown on plates containing 200g / L glucose and 35g / L isoleucine, expand the cultivation in the strain room to produce first-grade seeds, and then connect them to the second-grade seed tanks to continue to expand the cultivation. The secondary seed medium formula in the secondary seed tank is: glucose: 2.2g / L, corn steep liquor: 20g / L, dipotassium hydrogen phosphate: 3g / L, ammonium sulfate: 25 g / L, magnesium sulfate: 0.15 / g / L, V H : 3.0μg / L, Molasses: 25g / L, Thiamine: 500μg / L, V B1 : 0.2g / L, the strain index obtained by the secondary seed solution in the secondary seed tank after decontamination, cooling, and cultivation is: △OD=1.05, Gram staining is positive;

[0034] (2) fermentation

[0035] Put the secondary seed liquid into the fermenter equipped with the fermentation medium. The batchin...

example 2

[0049] The difference between example 2 and example 1 is that the formula of secondary seed culture medium formula is different from the formula of fermentation medium formula, and processing step is identical with example 1 so omits. Among them, the secondary seed medium formula is: glucose: 3.0g / L, corn steep liquor: 25g / L, dipotassium hydrogen phosphate: 3g / L, ammonium sulfate: 30g / L, magnesium sulfate: 0.15 / g / L, V H : 4.0μg / L, Molasses: 50g / L, Thiamine: 600μg / L, V B1 : 0.3g / L, the strain index obtained by the secondary seed solution in the secondary seed tank after decontamination, cooling, and cultivation is: △OD=1.16, Gram staining is positive;

[0050] The formula of the fermentation medium is: glucose: 160g / L, ammonium sulfate: 50g / L, corn steep liquor: 20g / L, magnesium sulfate: 0.2g / L, potassium dihydrogen phosphate: 3.0g / L, V B1 : 0.2g / L, V H : 4.0μg / L, molasses: 30g / L, thiamine: 600μg / L, the secondary seed liquid and the fermentation medium are continuously fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com