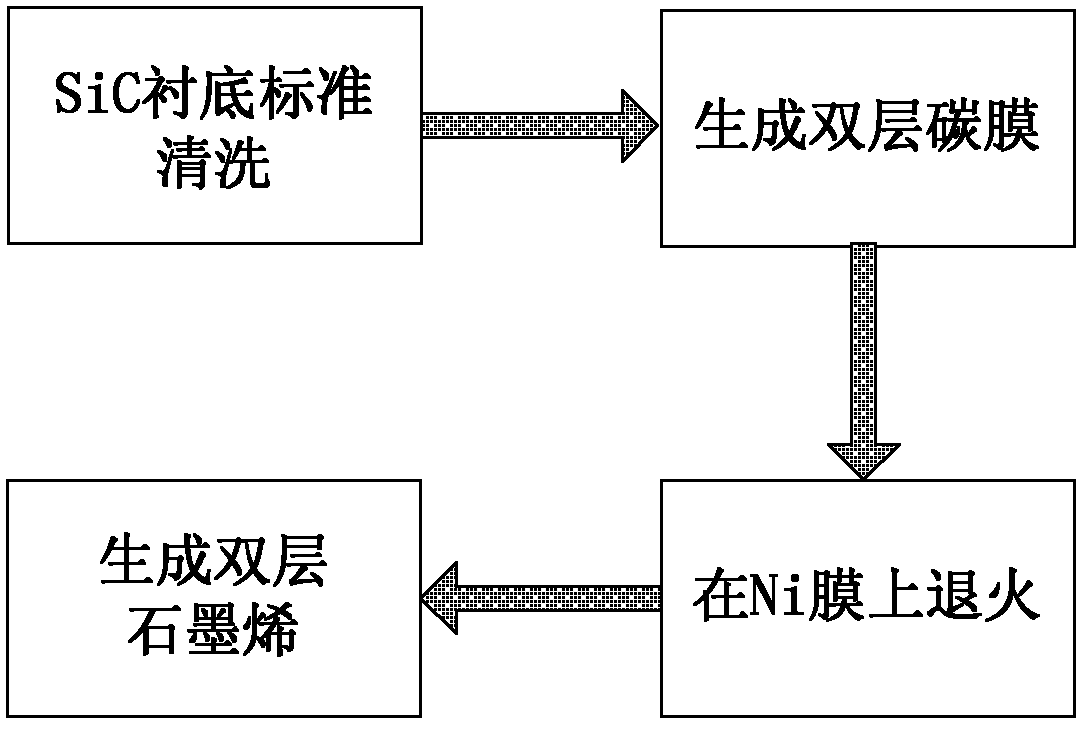

Preparation method of graphene on SiC substrate based on Ni film-aided annealing

A graphene and annealing technology, applied in the field of microelectronics, can solve the problems of complex process, high production cost, large energy consumption, etc., and achieve the effects of simple process, low porosity and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Clean the 6H-SiC sample to remove surface contamination.

[0023] (1.1) Use NH for 6H-SiC substrate 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample;

[0024] (1.2) Use HCl+H to remove the 6H-SiC sample after removing the surface organic residues 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0025] Step 2: Put the 6H-SiC sample into the quartz tube, and heat it with exhaust gas.

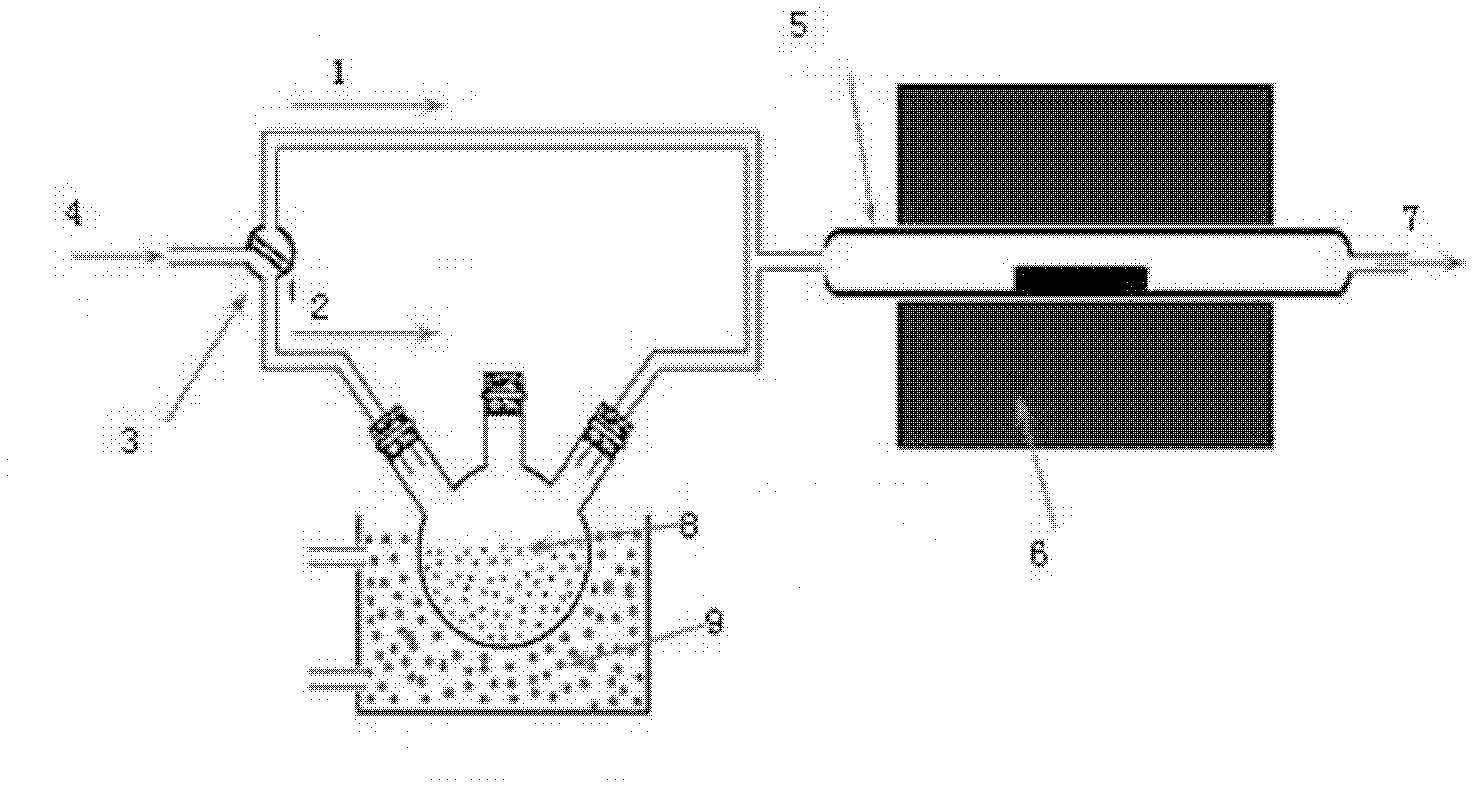

[0026] (2.1) Put the cleaned 6H-SiC sample into the quartz tube 5, and place the quartz tube in the resistance furnace 6;

[0027] (2.2) Check the airtightness of the whole preparation equipment, feed the Ar gas with a flow rate of 80ml / min from the air inlet 4, and use the three-way valve 3 to control the Ar gas to enter from the first passage 1 to empty the quartz tube for 30 Minutes, the air in the quartz tube is discharg...

Embodiment 2

[0038] Step 1: Clean the 4H-SiC sample to remove surface pollutants.

[0039] For 4H-SiC substrates, use NH first 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0040] Step 2: Put the 4H-SiC sample into the quartz tube, and heat it with exhaust gas.

[0041] Place the cleaned 4H-SiC sample in the quartz tube 5, and place the quartz tube in the resistance furnace 6; check the airtightness of the entire preparation equipment, and pass into the Ar gas with a flow rate of 80ml / min from the air inlet 4 , and use the three-way valve 3 to control Ar gas to enter from the first channel 1 to empty the quartz tube for 30 minutes, so that the air in the quartz tube is discharged from the gas outlet 7; turn on the power switch of the resistance furnace, and heat the ...

Embodiment 3

[0048]Step A: Clean the surface of the 6H-SiC substrate, that is, use NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; then use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0049] Step B: Place the cleaned 6H-SiC sample in the quartz tube 5, and place the quartz tube in the resistance furnace 6; check the airtightness of the entire preparation equipment, and the flow rate from the air inlet 4 is 80ml / min Ar gas, and use the three-way valve 3 to control the Ar gas to enter the quartz tube from the first channel 1 to empty the quartz tube for 30 minutes, so that the air in the quartz tube is discharged from the gas outlet 7; open the resistance furnace power switch, and the quartz tube is heated up to 1150°C.

[0050] Step C: turn on the water bath 9 power supply, to house CCl 4 Heat the liquid three-necked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com